Silica-based cathode enables long-life Li-S batteries

Green Car Congress

JUNE 7, 2020

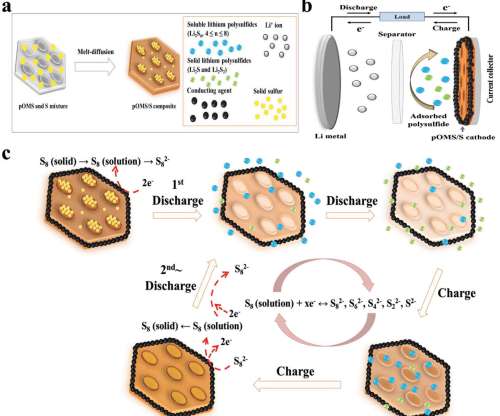

Scientists from the Daegu Gyeongbuk Institute of Science and Technology, Korea, have developed a novel silica-based cathode for lithium–sulfur batteries, thereby enabling the realization of batteries that can last for more than 2,000 charge/discharge cycles. However, using sulfur in batteries is tricky for two reasons.

Let's personalize your content