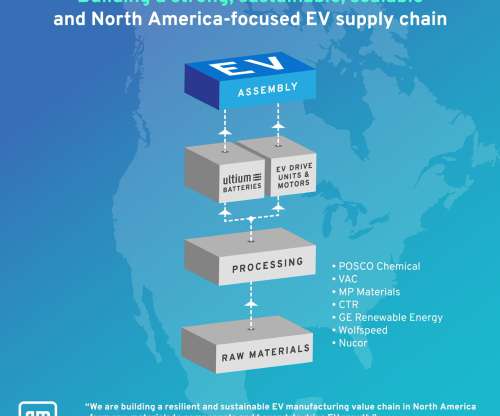

Government of Canada, Québec invest in GM-POSCO CAM plant in Québec

Green Car Congress

JUNE 1, 2023

CAM are key battery materials that consist of components such as processed nickel, lithium and other materials that make up about 40% of the cost of a battery. The project was first announced in March 2022 to supply General Motors’ fast-expanding battery production in North America.

Let's personalize your content