Uppsala U team identifies main performance bottlenecks in Li-sulfur battery performance

Green Car Congress

MARCH 28, 2022

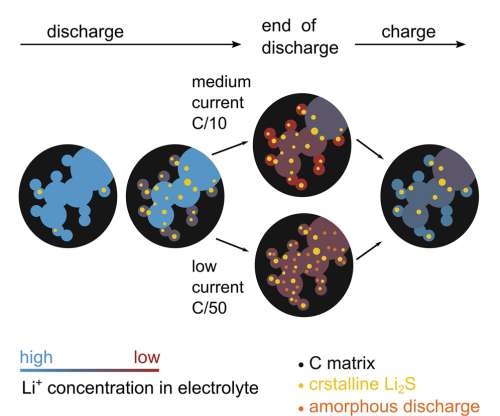

Lithium-sulfur batteries are prospects for future batteries as they are made from cheaper and more environmentally friendly materials than lithium-ion batteries. They also have higher energy storage capacity and work well at much lower temperatures. However, they suffer from short lifetimes and energy loss.

Let's personalize your content