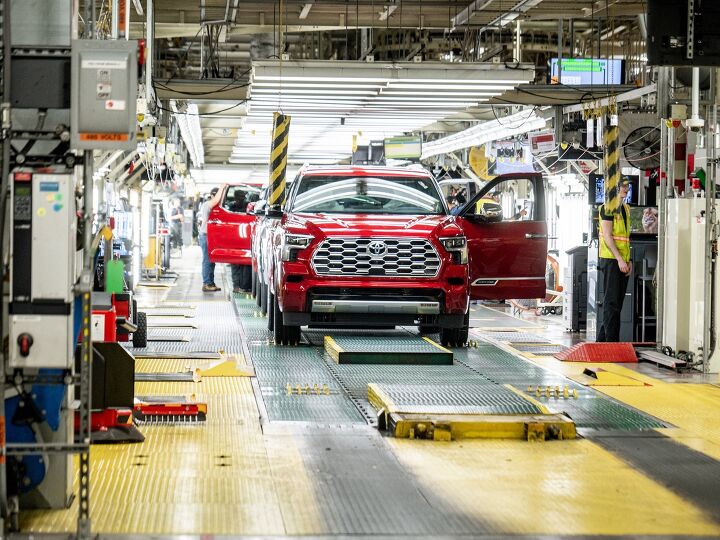

Toyota Assembly Plant in Texas Turns Twenty

Whilst we don’t generally run news of this sort, it is worth noting that this month represents a full two decades since Toyota put shovels in the ground to build what would become their San Antonio truck plant, a spot which currently cranks out Tundra and Sequoia machines.

Why is it worth noting? Because the products that pop from this plant are one of the few that have had even a meager amount of success in challenging the Detroit Three in the half-ton truck game. Other challengers have come and gone but the Tundra and Sequoia have managed to stick around and be relatively successful. That’s something to crow about – even if the market share of these models remains a sliver of what Detroit grabs every year.

Since breaking ground in 2003, Toyota Texas has assembled upwards of 3 million trucks and SUVs since production started in 2006. The company claims this place represents $4.2 billion in the Lone Star State, though specifics on that figure are tough to nail down. Suffice it to say that any automotive plant producing this many vehicles has far-reaching positive effects on the area in which it is located, from direct jobs to supplier contracts to local businesses that benefit from people spending their Toyota paychecks.

If you need a brief history lesson, the Tundra has been produced steadily at this facility since it opened in 2006, though the Sequoia only began life there in 2022. That was one year after Tacoma production was shuttled off elsewhere, ending an 11-year run that began in 2010. Through the third quarter of this annum, just over 92,000 Tundra pickups have been sold plus about 15,000 Sequoia SUVs.

Toyota has also donated more than $50 million to local nonprofit organizations, including a hundred grand this week to The Institute for School & Community Partnerships at Texas A&M University San Antonio and The 100 Club of San Antonio. It seems the names of societies in Texas are as big as the state itself.

[Images: Toyota]

Become a TTAC insider. Get the latest news, features, TTAC takes, and everything else that gets to the truth about cars first by subscribing to our newsletter.

Matthew buys, sells, fixes, & races cars. As a human index of auto & auction knowledge, he is fond of making money and offering loud opinions.

More by Matthew Guy

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- NotMyCircusNotMyMonkeys so many people here fellating musks fat sack, or hodling the baggies for TSLA. which are you?

- Kwik_Shift_Pro4X Canadians are able to win?

- Doc423 More over-priced, unreliable garbage from Mini Cooper/BMW.

- Tsarcasm Chevron Techron and Lubri-Moly Jectron are the only ones that have a lot of Polyether Amine (PEA) in them.

- Tassos OK Corey. I went and saw the photos again. Besides the fins, one thing I did not like on one of the models (I bet it was the 59) was the windshield, which looked bent (although I would bet its designer thought it was so cool at the time). Besides the too loud fins. The 58 was better.

Comments

Join the conversation

Is that 3 million vehicle number correct? It averages out to 150,000 vehicles a year, that seems like a rather lower volume plant.

Too bad for all of those rusty truck frames getting through.