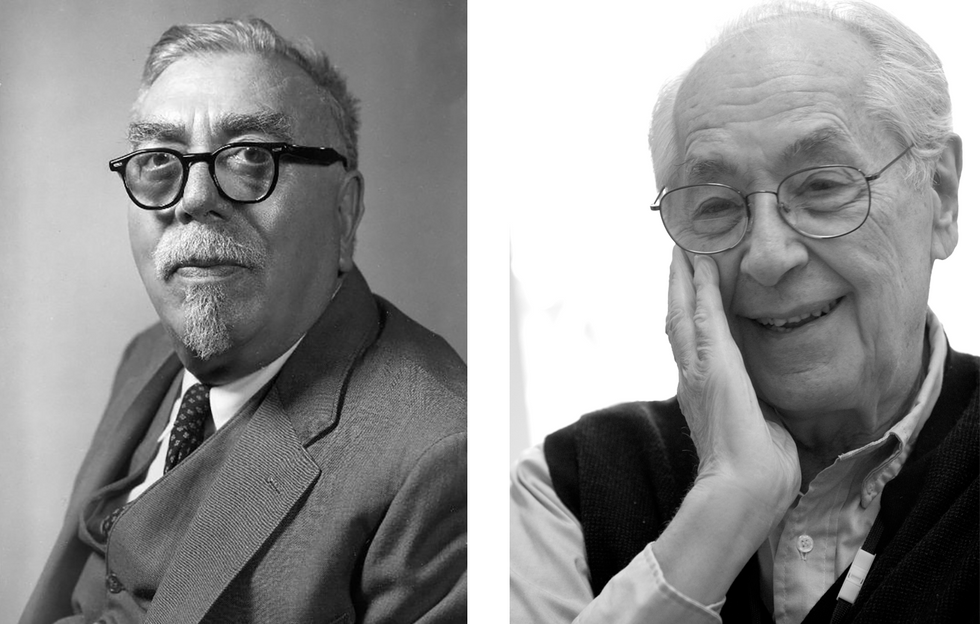

In 1961, Norbert Wiener, the father of cybernetics, broke his hip and wound up in Massachusetts General Hospital. Wiener’s bad luck turned into fruitful conversations with his orthopedic surgeon, Melvin Glimcher. Those talks in turn led to a collaboration and an invention: the Boston Arm, an early myoelectric prosthesis. The device’s movements were controlled using electrical signals from an amputee’s residual bicep and tricep muscles.

What was the Boston Arm?

Wiener had first postulated that biological signals could be used to control a prosthesis in the early 1950s, but research in this area did not flourish in the United States.

Instead, it was Russian scientist Alexander Kobrinski who debuted the first clinically significant myoelectric prosthesis in 1960. Its use of transistors reduced the size, but the battery packs, worn in a belt around the waist, were heavy. A special report in the Canadian Medical Association Journal in 1964 deemed the prosthesis cosmetically acceptable and operationally satisfactory, with a few drawbacks: It was noisy; it only had two motions—the opening and closing of the hand; and it came in just one size—appropriate for an average adult male. Historically, most upper arm amputations resulted from combat injuries and workplace accidents, and so had disproportionately affected men. But the use of thalidomide during pregnancy in the early 1960s resulted in an increase of babies of both genders born missing limbs. There was a need for prosthetics of different sizes.

In 1961, Glimcher traveled to the Soviet Union to see a demo of the Russian Hand. At the time, he was working one day a week at the Liberty Mutual Rehabilitation Center, treating amputees. Glimcher and Thomas Delorme, the center’s medical director, noticed that many amputees were not using their prostheses due to the limitations of the devices. Liberty Mutual Insurance Co., which ran the rehab center, had a financial interest in developing better prostheses so that their users could get back to work and get off long-term disability. The company agreed to fund a working group to develop a myoelectric prosthetic arm.

References

I first came across the Boston Arm when I was researching Norbert Wiener’s “hearing glove,” a device to help people who are deaf and hard of hearing interpret sound waves. A search of the MIT Museum’s database came up empty (no known example of the hearing glove exists), but I did find the entry on the Boston Arm. Curator Deborah Douglas sent me digitized copies of Ralph Alter’s doctoral thesis, a press release on the Boston Arm, and numerous press clippings.

Looking for a broad overview of the history of prosthetics, I found “The evolution of functional hand replacement: From iron prostheses to hand transplantation” by Kevin Zuo and Jaret Olson (Plastic Surgery vol. 22, no. 1, Spring 2014) to be particularly useful, as was “Historical Aspects of Powered Limb Prostheses” by Dudley Childress (Clinical Prosthetics & Orthotics, vol. 9, no. 1, 1985).

The Office of Technology Assessment closed in 1995, but Princeton University hosts the legacy site, which has a full run of the agency’s digitized reports, including Health Technology Case Study 29, “The Boston Elbow.”

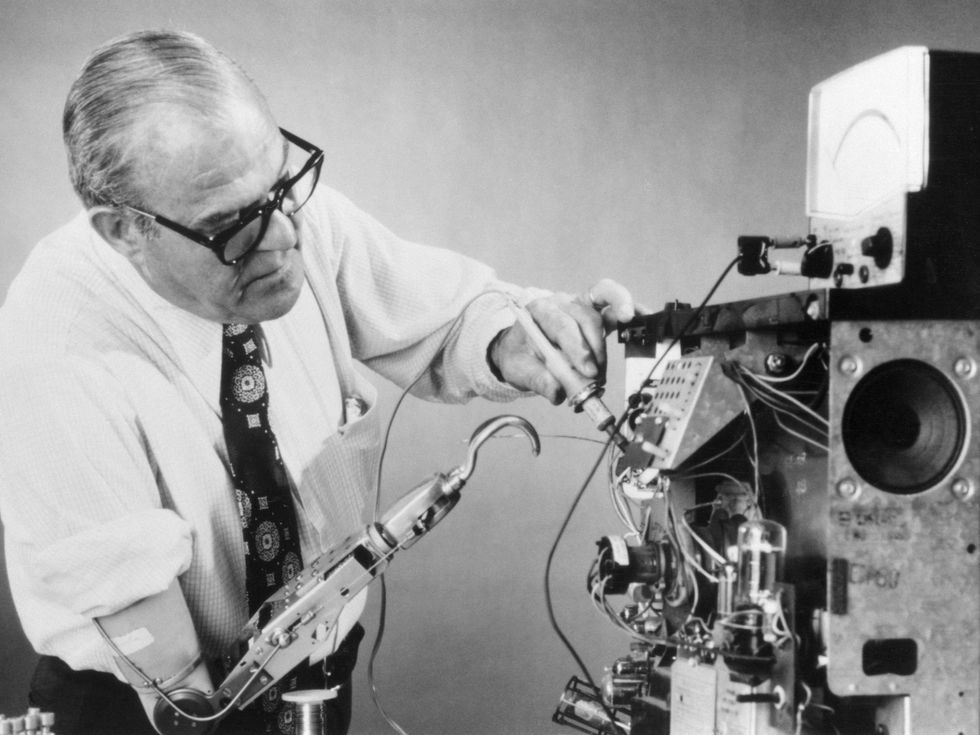

Wiener suggested that Amar G. Bose, a professor of electrical engineering at MIT, and Robert W. Mann, a professor of mechanical engineering also at MIT, join the group. Bose and Mann in turn recruited grad students Ralph Alter, to work on signal processing and software, and Ronald Rothschild, to work on hardware. Over the next few years, this collaboration of MIT, Harvard Medical School, Massachusetts General Hospital, and Liberty Mutual developed the Boston Arm.

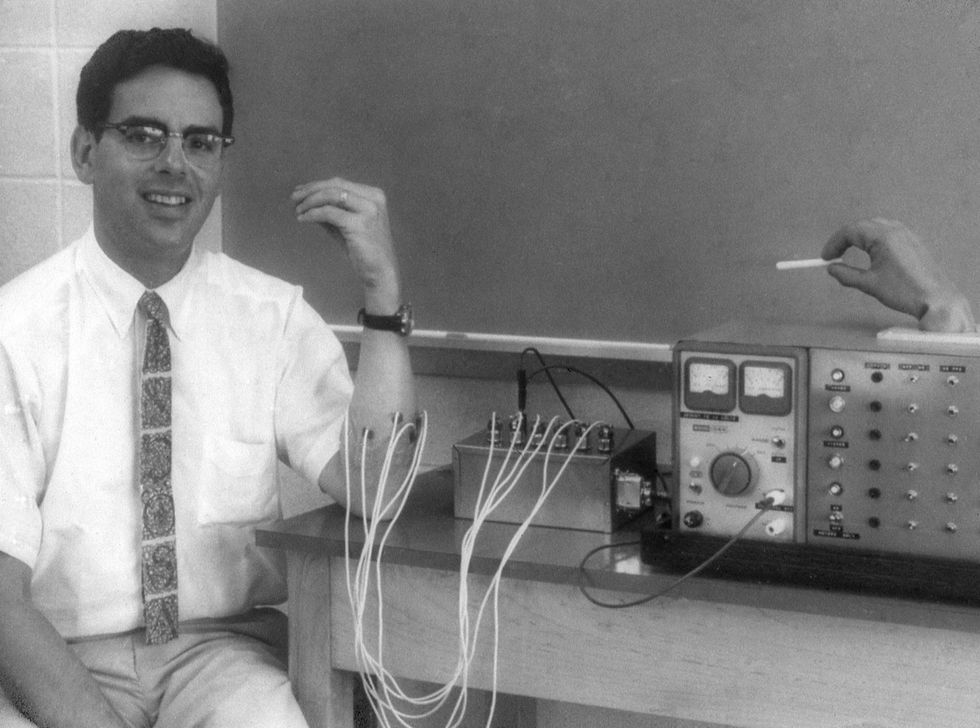

In 1966, MIT’s Research Laboratory of Electronics published Alter’s doctoral thesis, “Bioelectric Control of Prostheses,” as Technical Report 446. Alter had studied the electromyographic (EMG) signals stemming from muscle tissue and concluded they could be used to control the prosthesis. Meanwhile, Rothschild was working on his master’s thesis, “Design of an externally powered artificial elbow for electromyographic control.” Working with Alter, Rothschild designed, constructed, and demonstrated a motor-driven elbow controlled by emg signals.

Even as Rothschild and Alter were putting the final touches on their theses, Glimcher was teasing the press with the group’s experimental results during the summer of 1965. TheNew York Times ran a story claiming “New Process Will Help Amputee To Control Limb With Thought.” TheBoston Globe was a bit more sensational, comparing the prosthetic device to black magic and supernatural abilities. Glimcher did try to temper expectations, explaining that practical use of the arm was still a number of years away.

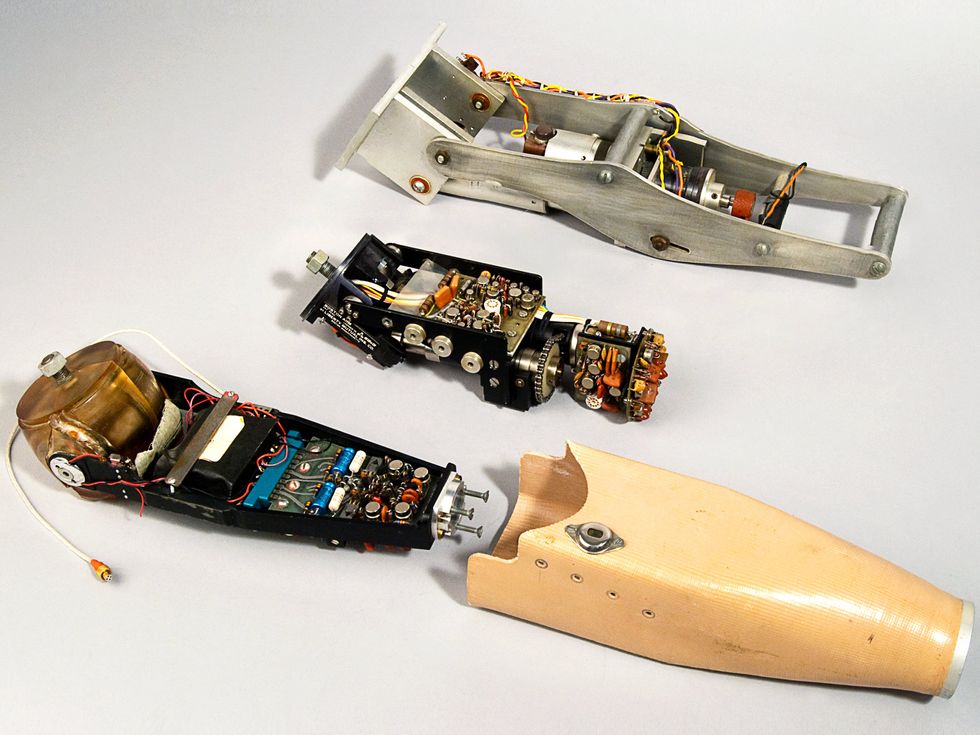

After many design iterations and improvements, the Boston Arm debuted in 1968 at a press conference at Massachusetts General Hospital. (Technically, it was an elbow rather than an arm, and in medical circles and technical reports, it was called the Boston Elbow. But colloquially and in the popular press, the name “Boston Arm” stuck.) Although the Boston Arm mostly remained a research project, several hundred were produced and fitted to amputees by the R&D company Liberating Technologies.

The Boston Arm, in turn, influenced the Utah Artificial Arm, developed by Stephen Jacobsen, who had completed his Ph.D. in 1973 at MIT under Robert Mann and then returned to his alma mater, the University of Utah. The Utah Arm went on to become one of the most widely used myoelectric prosthetics.

Was the Boston Arm a success?

In 1984, the U.S. Congress’s Office of Technology Assessment (OTA) analyzed the Boston Arm as Health Technology Case Study 29, part of its assessment of the medical devices industry.

It is a fascinating read, and it does not mince words. The first iterations of the Boston Arm, it concluded, “were by all accounts failures.” Eighteen were produced and fitted to an amputee, and every single user rejected it. The most serious problem, similar to the Russian Hand, was the bulky, belt-worn rechargeable battery, which had a limited charge. MIT students and employees went back to work, improving the battery and creating a slimmer profile for the device. The several hundred that were produced enjoyed better adoption, according to the OTA report.

The newer version of the Boston Arm weighed about 1.1 kilograms, could lift 23 kg, and could hold over 22.7 kg in a locked position. It had a battery life of about 8 hours, and charging took about 2 hours. It had a range of 145° from full flection to full extension, a distance covered in approximately 1 second. It had an estimated service life of five years, with a recommended annual tune-up that required shipping the elbow back to Liberty Mutual for adjustments.

The first iterations of the Boston Arm were by all accounts failures.

In 1983, about 100 people were regularly using the Boston Arm out of an estimated 30,000 to 40,000 people with above-elbow amputations in the United States. Why wasn’t it more widely adopted? Cost was one major hurdle. The base cost of the Boston Arm was US $3,500, but that rose to $9,500 (more than $29,000 in today’s dollars) once it was properly fitted. The Utah Arm, the only commercially available myoelectric alternative to the Boston Arm, had a full fitting cost of $20,000. In comparison, the total cost for a mechanical cable elbow prosthesis averaged about $1,500 (including the price of the socket and the fitting) and had a service life of 10 years. The OTA report quoted an engineer at the National Institute of Handicapped Research describing the Boston Arm as “essentially overkill”—”an unnecessarily complex technology at a correspondingly high price,” the report stated. In the engineer’s opinion, the Boston Elbow did not outperform a conventional mechanical prosthesis.

Of course, cost takes on a different meaning depending on who is paying. What may be an exorbitant price for a consumer might be a shrewd calculation for a business. Liberty Mutual marketed the Boston Arm as a “worker’s arm,” and in advertising materials the battery life was described as “a full 8-hour work day.” The majority of amputees fitted with a Boston Arm happened to be covered by Liberty Mutual’s worker’s compensation insurance. Getting them back on the job motivated the research and development process.

But cost is not the only factor in determining what type of prosthesis to choose, or whether to use one at all. The OTA report acknowledged the psychological impact of amputation and the idiosyncratic and contextual nature of individual choice. Depending on the amputee’s situation, a prosthesis may or may not be the right choice. The latest electrotechnology may not be better than a mechanical design that had been in use for more than 100 years.

Were prosthetic users involved in the R&D process?

I’m the type of person who always jumps to the end of a book, just to see how things work out, so it is no surprise that I read the last section of Alter’s thesis, “Suggestions for the Future,” first. One sentence stood out: “Thus far, only two persons have operated the prosthetic system.”

One person was Alter himself, even though he had two fully functioning arms. The other was a 55-year-old male with a 25-year-old unilateral, above-elbow amputation. That user sat for one session, which lasted about two hours. Presumably Glimcher would have provided some background from users based on his clinical experience. Later, Neville Hogan, director of the Eric P. and Evelyn E. Newman Laboratory for Biomechanics and Human Rehabilitation at MIT, involved other prosthetic users in the research process, as shown in this short undated video:

Robert W. Mann’s “Boston Arm”www.youtube.com

But a question still looms large in my mind, especially after I read Britt H. Young’s critique of the modern prosthetics industry and the editorial reflections of Spectrum editor-in-chief Harry Goldstein: Might the Boston Arm have seen wider adoption if potential users had been a more integral part of its development?

I’m currently teaching a history of industrial design course, part of a program for first-generation college students who plan to major in computer science and engineering. Student retention is the program’s primary goal. But my personal goal for the course is to help these new students think about inclusive, user-centered design from the start. Imagine how adding that perspective could change the future of engineering.

Part of a continuing serieslooking at historical artifacts that embrace the boundless potential of technology.

An abridged version of this article appears in the August 2023 print issue as “Ode to an Arm.”

- Creating a Prosthetic Hand That Can Feel ›

- Winner: The Revolution Will Be Prosthetized ›

- The Bionic-Hand Arms Race ›

Allison Marsh is a professor at the University of South Carolina and codirector of the university's Ann Johnson Institute for Science, Technology & Society. She combines her interests in engineering, history, and museum objects to write the Past Forward column, which tells the story of technology through historical artifacts.