Honda Patents Seats With Shock Absorption

Modern car seats are notoriously uncomfortable. We can blame manufacturers for cutting costs while seeking to standardize snazzier equipment elsewhere. Buyers often don’t consider the importance of seat comfort, especially when they’re only spending 10 minutes on a test drive. However, worsening road conditions have made us long for prior decades when car companies went overboard with the springs and foam.

The industry knows this and the phenomenon may even help explain the popularity of crossover vehicles, which often have softer suspensions than their sedan counterparts. But Honda is working on something that would bring the buffering inside the cabin.

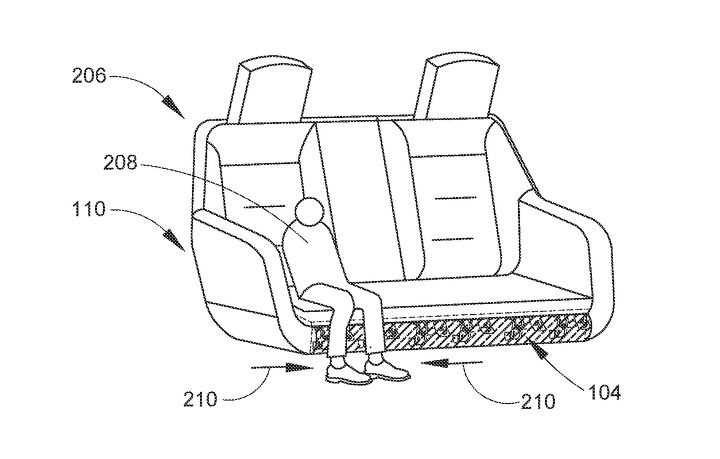

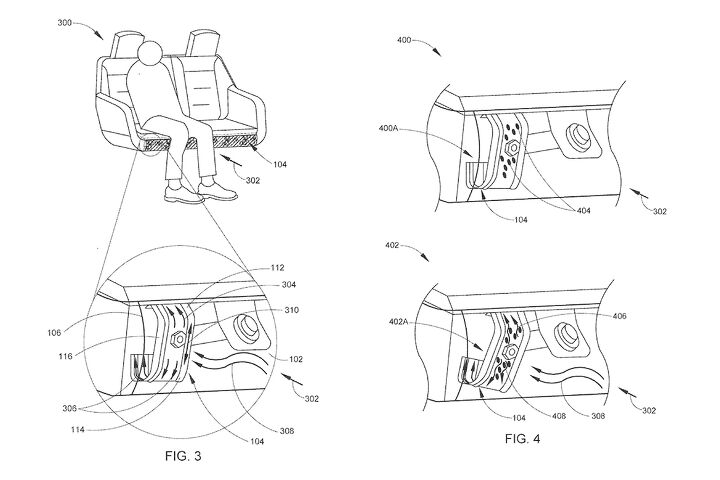

According to a report from CarBuzz, the Japanese automaker has filed a patent with the United States Patent and Trademark Office for shock absorbers mounted directly to the seat frame. It’s basically a secondary suspension just for the seating and is designed to help smooth out any bumps the external springs couldn’t handle.

Though the system also seems to be designed to help minimize injuries during a serious accident as well.

From CarBuzz:

Honda specifically points to body regions like the tibia and elbow being affected in a discomforting manner. With additional shock absorbers as part of the seat frame, however, the remaining impact load can be absorbed before it unsettles occupants.

Honda repeatedly references "collisions" in the patent documentation, but we presume this doesn't only involve serious crashes, but also when the wheels strike bumps, hit objects like rocks and potholes in the road, or traverse rougher terrain. However, the company also stated that the seat shock absorbers could help cushion occupants in the event of a more serious collision with another car or a tree. This makes sense due to the forces that our bodies are subjected to in a crash, when the main point of contact is with the seat.

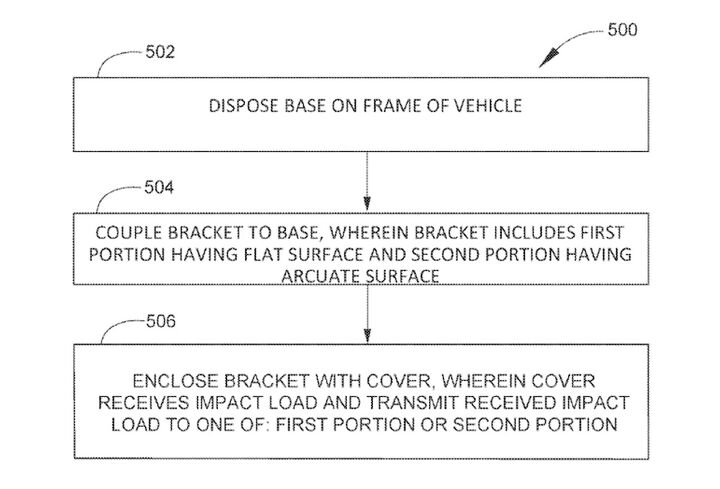

"In certain cases, during severe collisions of obstacles against the vehicle, the external shock absorbers may partially absorb the impact load and transmit the remaining impact load to the occupant compartment," says the description of the device. "The bracket located in the occupant compartment may absorb the remaining impact load that may not be dampened by the external shock absorbers."

The associated documentation is primarily about how these shock absorbers would mount to the vehicle frame using brackets. Everything else is basically there to make the explanation as broad as possible for the sake of legal protections, as “suspension seats” already exist. But Honda’s unit would function differently.

Rather than having an embedded webbing of springy textile materials designed to keep your tailbone from being destroyed while off-roading, the patented shock absorbers are separate from the seat itself. Based on the USPTO filing, the flat and rounded surfaces are connected by brackets and designed to redirect the load.

On smaller bumps, they’re supposed to create a smoother ride by evening out harsh vibrations. When exposed to a serious impact, the bracket itself is intended to warp as a way to help minimize the forces being inflicted upon passengers. Since the moment should be minimal the system is intended to be used with airbags — assuming Honda decides to implement it.

[Images: USPTO]

Become a TTAC insider. Get the latest news, features, TTAC takes, and everything else that gets to the truth about cars first by subscribing to our newsletter.

A staunch consumer advocate tracking industry trends and regulation. Before joining TTAC, Matt spent a decade working for marketing and research firms based in NYC. Clients included several of the world’s largest automakers, global tire brands, and aftermarket part suppliers. Dissatisfied with the corporate world and resentful of having to wear suits everyday, he pivoted to writing about cars. Since then, that man has become an ardent supporter of the right-to-repair movement, been interviewed on the auto industry by national radio broadcasts, driven more rental cars than anyone ever should, participated in amateur rallying events, and received the requisite minimum training as sanctioned by the SCCA. Handy with a wrench, Matt grew up surrounded by Detroit auto workers and managed to get a pizza delivery job before he was legally eligible. He later found himself driving box trucks through Manhattan, guaranteeing future sympathy for actual truckers. He continues to conduct research pertaining to the automotive sector as an independent contractor and has since moved back to his native Michigan, closer to where the cars are born. A contrarian, Matt claims to prefer understeer — stating that front and all-wheel drive vehicles cater best to his driving style.

More by Matt Posky

Latest Car Reviews

Read moreLatest Product Reviews

Read moreRecent Comments

- Dartdude Having the queen of nothing as the head of Dodge is a recipe for disaster. She hasn't done anything with Chrysler for 4 years, May as well fold up Chrysler and Dodge.

- Pau65792686 I think there is a need for more sedans. Some people would rather drive a car over SUV’s or CUV’s. If Honda and Toyota can do it why not American brands. We need more affordable sedans.

- Tassos Obsolete relic is NOT a used car.It might have attracted some buyers in ITS DAY, 1985, 40 years ago, but NOT today, unless you are a damned fool.

- Stan Reither Jr. Part throttle efficiency was mentioned earlier in a postThis type of reciprocating engine opens the door to achieve(slightly) variable stroke which would provide variable mechanical compression ratio adjustments for high vacuum (light load) or boost(power) conditions IMO

- Joe65688619 Keep in mind some of these suppliers are not just supplying parts, but assembled components (easy example is transmissions). But there are far more, and the more they are electronically connected and integrated with rest of the platform the more complex to design, engineer, and manufacture. Most contract manufacturers don't make a lot of money in the design and engineering space because their customers to that. Commodity components can be sourced anywhere, but there are only a handful of contract manufacturers (usually diversified companies that build all kinds of stuff for other brands) can engineer and build the more complex components, especially with electronics. Every single new car I've purchased in the last few years has had some sort of electronic component issue: Infinti (battery drain caused by software bug and poorly grounded wires), Acura (radio hiss, pops, burps, dash and infotainment screens occasionally throw errors and the ignition must be killed to reboot them, voice nav, whether using the car's system or CarPlay can't seem to make up its mind as to which speakers to use and how loud, even using the same app on the same trip - I almost jumped in my seat once), GMC drivetrain EMF causing a whine in the speakers that even when "off" that phased with engine RPM), Nissan (didn't have issues until 120K miles, but occassionally blew fuses for interior components - likely not a manufacturing defect other than a short developed somewhere, but on a high-mileage car that was mechanically sound was too expensive to fix (a lot of trial and error and tracing connections = labor costs). What I suspect will happen is that only the largest commodity suppliers that can really leverage their supply chain will remain, and for the more complex components (think bumper assemblies or the electronics for them supporting all kinds of sensors) will likley consolidate to a handful of manufacturers who may eventually specialize in what they produce. This is part of the reason why seemingly minor crashes cost so much - an auto brand does nst have the parts on hand to replace an integrated sensor , nor the expertice as they never built them, but bought them). And their suppliers, in attempt to cut costs, build them in way that is cheap to manufacture (not necessarily poorly bulit) but difficult to replace without swapping entire assemblies or units).I've love to see an article on repair costs and how those are impacting insurance rates. You almost need gap insurance now because of how quickly cars depreciate yet remain expensive to fix (orders more to originally build, in some cases). No way I would buy a CyberTruck - don't want one, but if I did, this would stop me. And it's not just EVs.

Comments

Join the conversation

Ironically, the best vehicle seats I've experienced were the hardest. The first new car I owned, a '78 Audi Fox, had seats upholstered in a tan velour, with very firm foam, with a nice ergonomic shape, including built-in lumbar support. The velour was also pretty grippy, which helped hold you in place in cornering.

i have found seats in my last 3 vehicles progressively more in comfortable after being in them 45 minutes. The last time. I experienced comfort was in a 98 Camry xle.