Wind-to-Hydrogen Tech Goes to Sea

Is electrolysis cheaper offshore? Siemens Energy and the H2Mare project will find out

In a future wind farm, far out at sea, each individual wind turbine could have all the necessary systems to produce hydrogen on a platform affixed to the turbine’s tower. Hydrogen from multiple turbines would be fed via pipeline to a Power-to-X platform [left] where the gas would be used to produce fuels such as methane or methanol.

Imagine this hopeful, and not impossible, energy scenario for the year 2040. Many countries have met their climate goals and are on track to be completely carbon neutral. Wind and solar parks produce a large portion of their energy. Then, as now, wind farms are operating off the world’s coasts—but not all of these offshore sites are connected to the mainland via underwater power cables.

Some of the wind farms instead sit in clusters more than 100 kilometers out at sea. They are highly automated production islands that directly convert wind energy to hydrogen, with a few of them processing the gas into fuels and other goods. In these clusters, the wind turbines are integrated with electrolyzers that generate hydrogen from desalinated seawater. Chemical plants on dedicated platforms then process part of the hydrogen, combining it with nitrogen to make ammonia, or with carbon dioxide to produce substitutes for fossil fuels.

Ships regularly dock at these offshore platforms to deliver raw materials and take away the fuels and goods produced, but all the processes are fully automated and largely self-sufficient. Someday, even the ships themselves might be autonomous. Back on shore, service technicians support operations remotely and only have to head out to sea a few times a year to check on machinery and make adjustments.

It seems like science fiction now, but major efforts are already underway to demonstrate the technologies needed to realize this vision. Most of the activity is in Europe, where there are at least 10 major offshore wind and hydrogen projects, including demonstration systems being built or planned in the North Sea, the Atlantic, and off the coast of Ireland. In France, for example, the hydrogen producer Lhyfe is operating a pilot project called SEM-REV off the coast of Saint-Nazaire, which has been producing small amounts of hydrogen since September 2022.

US $5 PER KILOGRAM

Cost of green hydrogen today. Conventional, or gray, hydrogen: $1.50 to $2.00

A British company, ERM, plans to have a 10-megawatt demonstration project called Dolphyn up and running off the coast of Aberdeen, Scotland, in 2026. Sweden’s Vattenfall is aiming to build an offshore, hydrogen-producing wind-turbine demonstrator in the same area. Denmark is planning a hydrogen island designed to generate about 1 million tonnes of offshore hydrogen starting in 2030. And the Norwegian company H2Carrier recently received approval in principle for its concept for an industrial-scale floating production unit to make green ammonia at sea.

Longer term, California, the Canadian province of Nova Scotia, Japan, and Western Australia are all looking to the sea to help meet their demands for hydrogen.

At Siemens Energy, we are working with a consortium of 32 partners from industry and academia on a wind-and-hydrogen project called H2Mare. Together, Siemens Energy and Siemens Gamesa are investing a total of €120 million in the technology. H2Mare began in 2021 and will run until 2025. By then, we expect to have tested a 5-MW offshore electrolysis system and a full process chain for fuel production at a scale of about 50 liters per day. We also expect to demonstrate the viability of other key concepts and systems, as well as the ability of these systems to interact with each other reliably in the harsh environment out at sea.

Europe Is Getting Serious About Developing a Hydrogen Economy

H2Mare is one of three hydrogen flagship projects that have received a total of €700 million in funding from the German Federal Ministry of Education and Research. And Germany isn’t the only country investing in hydrogen technologies. Even a casual reading of the business press might convince you that the world has fallen in love with this molecule. The European Union has approved over €10 billion in funding for hydrogen-related industrial projects. The U.S. Department of Energy has spent over US $9 billion on developing a hydrogen economy, with many of its initiatives specified in the Inflation Reduction Act of 2022. In mid-2022, the International Renewable Energy Agency counted 32 countries that had adopted hydrogen strategies and 11 others that were preparing such plans.

Why all the hype about hydrogen? In the fight against climate change, many countries have pledged to reduce their CO2 emissions to net zero. Unlike today, the future will see a climate-neutral world where energy will primarily be electricity from photovoltaics, wind turbines, and hydroelectric power plants. But not all of the vehicles, buildings, and industrial processes that now use fossil fuels can run on electricity alone. Airplanes, for example, won’t be able to fly long distances on battery power. In addition, for many uses, energy can’t be used the instant it’s generated but must be stored for hours or days and transferred across continents or even oceans, neither of which is currently economically or technologically feasible.

The upshot is that a portion of the green electricity will have to be converted to other types of energy appropriate for specific applications. Experts call this Power-to-X (PtX). These applications tend to be strongly clustered in three broad sectors: transportation, heating, and industry, in such segments as manufacturing and processing. All are quite energy intensive. Powering these applications will require electrifying these sectors or converting electricity to a more suitable form via PtX.

The European Union’s net-zero scenario for 2050 already calls for an installed offshore wind capacity of about 450 gigawatts for power generation

That’s where hydrogen comes into play. The technology to produce hydrogen by electrolyzing water has been around for more than 200 years. The gas can power fuel-cell vehicles or gas turbines; it can be used directly in chemical processes or converted with CO2 to produce methane, methanol, and other substitutes for fossil fuels. If the electricity used to produce the hydrogen and the fuels derived from it comes from renewable sources, these products are considered “green.”

Hydrogen is thus greasing the wheels of the global transition to cleaner energy. And the world is going to need a lot more of it. In 2021, global hydrogen demand was 94 million tonnes, most of it used in refining and in chemical industries. Almost all hydrogen produced today is designated as brown, black, or gray, meaning it was generated by burning natural gas or coal. The process emits about 10 tonnes of CO2 per tonne of hydrogen. In the future we’ll need to replace this dirty hydrogen with green hydrogen, produced by electrolysis using renewable electricity.

Depending on how rapidly countries decarbonize, the International Energy Agency predicts that global demand for hydrogen will reach 115 to 130 million tonnes per year in 2030, about 30 million of which will come from low-emission production. However, much more than that will be needed for the world to achieve net-zero emissions by 2050. The IEA calculates this amount to be around 200 million tonnes of hydrogen in 2030, half of which would come from low-emission production. There’s still a long way to go: According to the IEA, not even 1 percent of hydrogen produced in 2021, amounting to 0.6 million tonnes, was low emission.

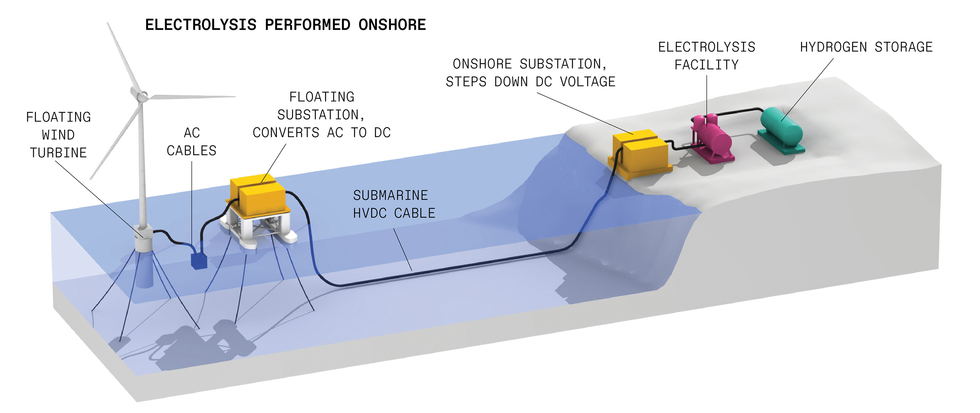

In one proposed configuration, where floating wind turbines are located more than about 60 kilometers out to sea, electricity would be transmitted via HVDC cables to an electrolyzer facility onshore.

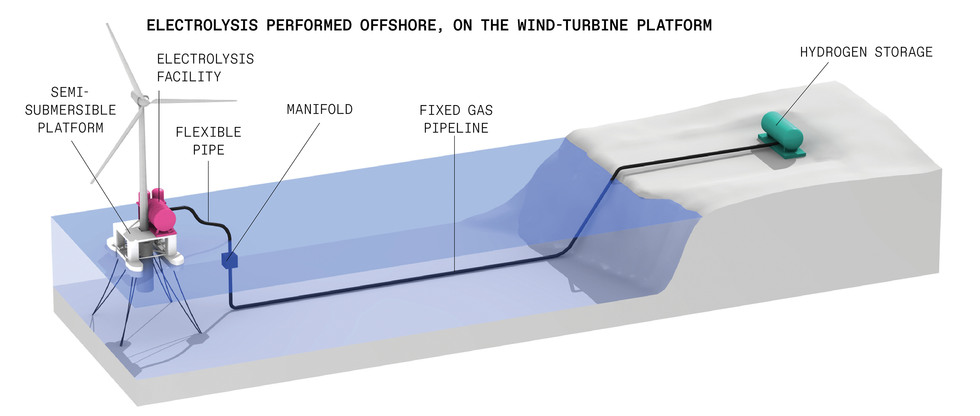

In the H2Mare research consortium, Siemens Energy is analyzing a decentralized configuration in which hydrogen is produced at each wind turbine. The gas could then be transferred by pipeline or ship.

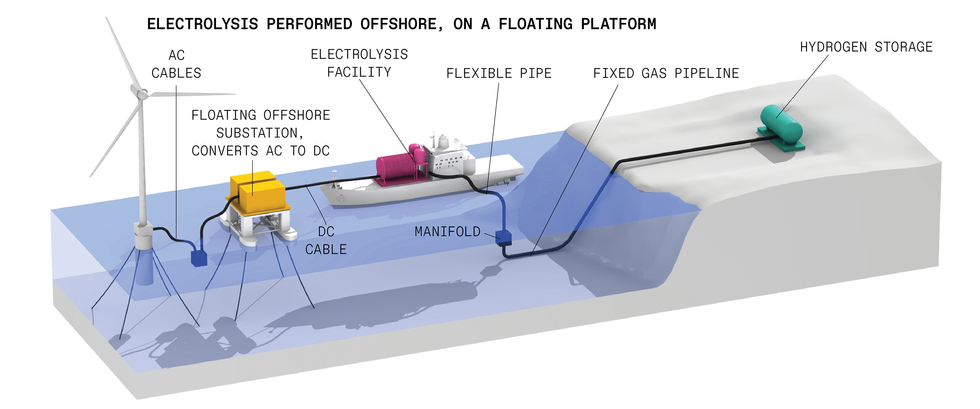

In a centralized configuration, multiple wind turbines offshore would feed a floating substation, which would convert AC to DC. The DC would then be used to generate hydrogen.

John MacNeill

Why It Makes Sense to Produce Hydrogen Offshore

How will offshore hydrogen generation fit into existing decarbonization plans? The European Union’s net-zero scenario for 2050 already calls for an installed offshore wind capacity of about 450 gigawatts for power generation. (Today, a typical offshore wind farm has about 1 GW of installed capacity; future farms will offer about 2 GW each.) Recent analysis, however, has suggested that the EU could install, for hydrogen production, a great deal more offshore wind generation beyond the 450 GW specified in the net-zero projections—perhaps hundreds of gigawatts more, in fact.

To meet such targets, it’ll be necessary to build, and build fast. Green hydrogen production requires electrolyzers, solar and wind parks, and clean water—about 10 liters per kilogram of hydrogen generated. Add to this the PtX systems to produce methane, methanol, synthetic e-fuels, and ammonia. For these green products to be competitive, the sites will have to offer low power-generation costs and will have to produce power at near-full capacity much of the time.

Offshore wind parks can meet both of these criteria. Offshore sites could make it possible for densely populated regions like Europe and Japan to generate at least part of their hydrogen close to coastal demand centers, thereby cutting transportation costs. Also, wind speeds are generally higher and steadier out at sea, permitting consistently greater output.

The savings would accrue from several factors. In a typical scenario, wind power out at sea would be converted only once to direct current and then used to electrolyze water. The water supply would literally surround the offshore platform—all that would be needed would be to desalinate and purify it. In contrast, electricity produced by offshore wind power typically requires multiple conversions and transmission across long distances before it’s fed into the grid or an electrolyzer onshore, processes that siphon off power and reduce efficiency. Delivery of hydrogen from offshore, on the other hand, would be easy via pipeline. PtX products such as methanol and ammonia would be even easier to transport than hydrogen, whether via pipeline or ship.

Key Questions That H2Mare Will Answer

Our H2Mare project has several major goals. We are doing the detailed analysis necessary to determine conclusively whether it will make economic sense, and be technically feasible, to produce hydrogen and other fuels offshore. And if so, how, exactly? What would be the best configurations, distances, production volumes, and so on? Although we’re not going to build a full-scale offshore PtX production platform, we do plan to build a test platform on a barge on the open sea, as well as an onshore test setup of the electrolysis system.

One of the most important questions we’ll be answering is, What is the best way to supply PtX production facilities out at sea? To produce fuels or goods such as ammonia, these facilities can be supplied with either hydrogen or with electricity; in the latter case, the PtX platform would produce its own hydrogen from electrolysis of desalinated seawater. But if the PtX facility is being furnished with hydrogen from other platforms, the question becomes, What is the best way to produce the gas? You could produce hydrogen at each wind turbine and then combine it at the PtX facility, or you could combine the electricity from multiple wind turbines to produce hydrogen on a separate platform and then supply it to the PtX platform. It turns out that the former option is better.

30 MILLION TONNES

Amount of low-emission hydrogen the IEA predicts will be produced in 2030

Another big question is how to achieve stable production for these multimegawatt wind-hydrogen islands as well as autonomous operation of the PtX islands. Regardless of whether hydrogen or PtX products are being generated, the production islands won’t be directly connected to an onshore power grid, and so they’ll need to operate reliably on their own.

That won’t be easy, given the extremely dynamic environment these platforms will have to function in. Offshore, the weather alternates among brisk winds, storms, and occasional lulls, sometimes going from one to another in mere minutes. That will mean great variability in the levels of power supplied by the wind turbines. As a result, the supply of electricity and hydrogen to the various facilities will vary widely.

That variability will also strain the electrical systems. Because there’s no grid connection, the platforms will basically operate as small, isolated power grids and therefore have to handle any sudden surges in power.

Conversely, after a long lull in the wind, the chemical plants and other offshore facilities will have to restart themselves without receiving external power. This is called black-start capability. There are no standard procedures for doing this in a tiny, automated, and isolated grid, so we are trying to devise some. We’re considering, for example, what kinds of batteries to use and how to design chemical processes so that the facilities can restart themselves reliably.

The electrolyzers, too, must be chosen for best performance in the dynamic environment out at sea. There are three main types of industrial electrolysis, and of the three, the proton-exchange-membrane (PEM) is ideal in this scenario. A PEM electrolyzer starts up within minutes and can handle rapid load changes. As part of H2Mare, we are designing and building PEM cells specifically for offshore use, and we expect to test them soon to see how well they perform when the power is highly variable.

H2Mare Project

Project goal:

Investigate offshore production of hydrogen and secondary products

Funding:

Partially funded by the German Federal Ministry of Education and Research

Duration:

April 2021 to March 2025

Consortium:

32 partners from industry and research

Project budget:

Approximately €150 million, about €100 million of which consists of subsidies

What we’re finding is that process control will play an important role. The individual electrolyzers connected to a turbine will need to be controlled in such a way that they age uniformly and their total downtime is kept to a minimum. Our experiments now are aimed at finding the most efficient operating mode. For example, there’s an investigation into whether the electrolyzer’s waste heat can be used for desalination, and if this amount of heat is sufficient over the entire operating range of the plant.

H2Mare will also look into initial strategies for managing a small island grid. What happens when an electrolyzer shuts down unexpectedly? Where can the excess electrical energy be channeled at a speed fast enough to prevent the grid from collapsing? And conversely, How can the electrolyzer be designed to handle a situation where the wind fades away and the power supply is suddenly gone?

To answer these questions, we intend to build and operate, in the next two years, a 5-MW electrolyzer with a seawater desalinization system in an onshore test. For the tests, we’ll re-create an offshore environment, including offshore-wind profiles.

From Here to Hydrogen

For the power generation and electrolysis systems, as well as the PtX facilities, the most important research objective is figuring out how to operate stably despite the dynamic environment, isolation, and automation. The chemical processes are generally most efficient when there’s a constant supply of power and reactants. But out at sea, they will inevitably fluctuate, so we’re developing concepts that use batteries or hydrogen-storage systems to smooth out the fluctuations. The trick will be to keep the cost of these buffers to a minimum. Another possibility is a modular design in which parallel modules are started up or shut down in coordination with one another.

The home base for much of our PtX-focused research is the Energy Lab 2.0 at Karlsruhe Institute of Technology. The lab has a variety of energy-related R&D facilities, including ones for renewable-energy generation, energy storage, and PtX, as well as smart-home and electric-vehicle infrastructure. For H2Mare, it serves as a kind of dry dock: There, we are operating the prototype PtX plants with power profiles typical for offshore wind farms and are simulating their optimal operation under transient conditions and in island mode.

Meanwhile, Siemens Energy is going ahead with plans to develop a commercial electrolysis system for offshore wind turbines. According to current estimates, the company’s first prototype of a wind turbine with integrated hydrogen production could be in the water in 2026, and commercial projects with capacities ranging from several hundred megawatts to gigawatt scale could follow by the end of the 2020s.

If it all goes well, offshore hydrogen could help enable the kind of rapid, mass-scale transition to climate-neutral energy that we’ll need to meet the goals for the 2040 time frame. We expect that self-sufficient commercial-scale PtX-production islands will be a realistic possibility, but not until 2040 at the earliest. Whether they’ll look and function exactly like those we’ve described in this article will depend in large measure on knowledge gained from H2Mare and from similar projects in Europe and elsewhere.

- 2022—The Year the Hydrogen Economy Launched? ›

- Wind-to-Hydrogen Production Reaches Deep Water ›

- Australia Goes All-in on Green Hydrogen ›