This sponsored article is brought to you by NYU Tandon School of Engineering.

With so many of the items we interact with in our daily lives — from soaps and fertilizers to pharmaceuticals to petrochemicals — deriving from products of the chemical industry, the sector has become a major source of economic activity and employment for many nations, including the United States and China. But as the global demand for chemical products continues to grow, so do the industry’s emissions.

These emissions are approaching a tipping point, and the companies responsible for creating these necessary products are increasingly looking at options to help offset their pollution outputs.

A range of government regulations aimed at achieving zero-carbon emissions are driving this migration. These greenhouse emissions regulations will progressively come into effect in the coming decades, culminating, for example, in the European Union’s aim to reduce 95 percent of 1990 level greenhouse emissions by 2050. These and other international regulations on greenhouse emissions could threaten up to 12 percent of all U.S. exports (US $220 billion). The task is clearly enormous, not just for the chemical manufacturing industry itself but for the larger economy.

Now, a new research organization has arisen to tackle the most daunting task looming over the industry: How to make industrial chemistry — especially petrochemistry — greener and more sustainable, partly to meet the escalating demands of these greenhouse emission regulations. The multi-institutional effort is called Decarbonizing Chemical Manufacturing Using Sustainable Electrification, or DC-MUSE, founded at the NYU Tandon School of Engineering and encompassing a number of schools and institutions.

“The chemical industry has unique needs, because there are different requirements within the sector,” says André Taylor, Center Director and Professor of Chemical and Biomolecular Engineering at NYU Tandon. “On one side, you have high volume, commodity chemicals that have low margins — products like feed stocks for example. And these are the products that generate most of the greenhouse gas emissions. But then you have specialty chemical companies that work with a little bit more higher end products that are low volume but highly profitable, like drugs and medications. They have the same problem with sustainability, but the solutions are different. That’s what DC-MUSE is addressing.”

A new start for decarbonizing chemical manufacturing

DC-MUSE was conceived in the summer of 2020 in a workshop attended by over 40 companies and institutions, and organized by a planning grant from the National Science Foundation to build capacity in convergent research. Its aim is to develop technologies and strategies to help the U.S. chemical industry migrate from thermal-based manufacturing processes to electricity-based ones.

Many experts believe that the first step in overhauling the chemical industry will involve moving away from thermally-driven chemical reactions and separation processes that require heat from fossil fuel combustion and moving towards reactions that use electricity generated by renewable resources, like wind and solar.

“DC-MUSE brings a unique contribution to the field of electrification of the chemical industry through our multidisciplinary approach,” says Elizabeth Biddinger, Deputy Director of DC-MUSE. “We are able to work on the nuances of electrified reactions from a fundamental through applied scale. We are able to model how these reactions would be implemented in the chemical plant and we are able to consider how the grid and chemical plant would work synergistically together.”

While this migration has already started to occur, with penetration of renewable sources into the U.S. electrical grid doubling in the past decade, the technologies for integrating these sources into cost-effective electrified chemical processes has remained practically non-existent.

DC-MUSE has already begun laying the groundwork for this endeavor, utilizing a multi-institution, collaborative approach to research and outreach, with the support of $1.2 million in grants from the Alfred P. Sloan Foundation. The researchers laid out the challenges they are facing in a paper in the journal Joule earlier this year.

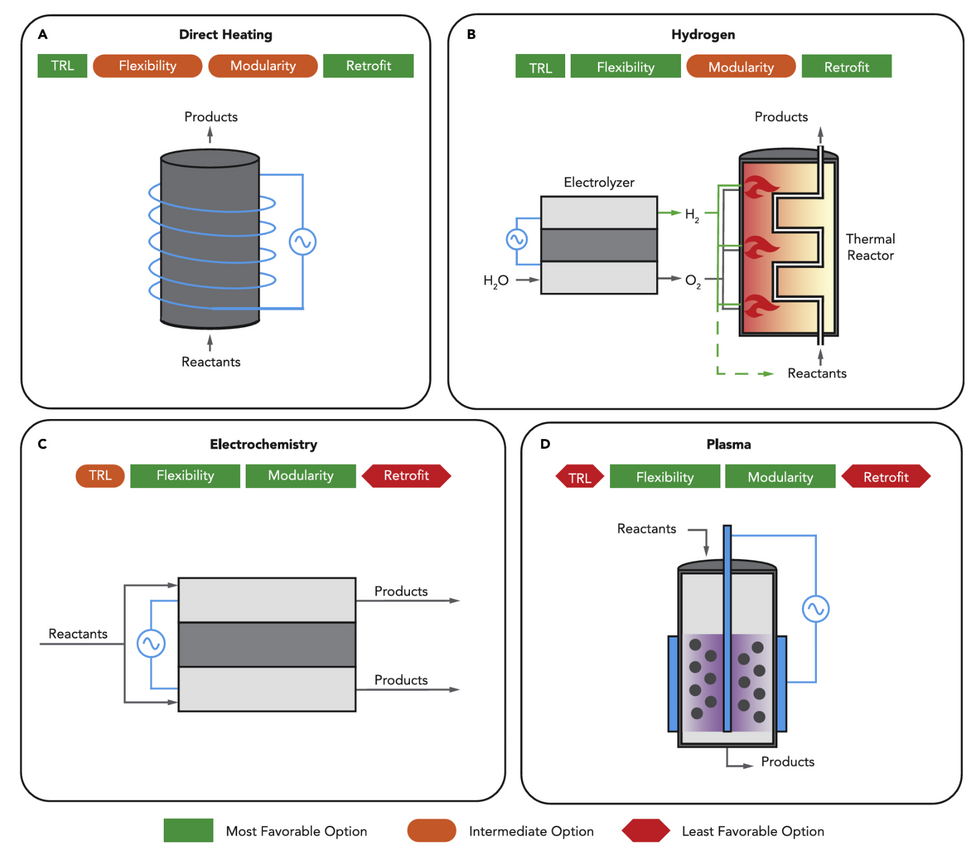

In the paper, the researchers identify four technological pathways — ranging from near-term options to further-out technologies in need of immediate research — with the goal of analyzing how effective they might be in long-term efforts for decarbonization.

The first two pathways directly substitute fossil fuel-produced heat (which facilitates the reactions inherent in chemical production) with electricity or electrochemically generated hydrogen. The researchers suggest that both options could be deployed now and potentially be used to retrofit existing facilities.

Electrolytic hydrogen is also highlighted as an opportunity to replace fossil fuel-produced hydrogen (a process that emits carbon dioxide) as a critical chemical feedstock. In 2020, fossil-based hydrogen supplied nearly all hydrogen demand (90 megatons) in the chemical and refining industries — hydrogen’s largest consumers.

The next two pathways introduced — utilizing electrochemistry and plasma — are less technologically mature but have the potential to replace energy- and carbon-intensive thermochemical processes currently used in the industry. By adopting electrochemical processes or plasma-driven reactions instead, chemical transformations can occur at lower temperatures and pressures, potentially enhancing efficiency.

A large barrier to deep decarbonization of chemical manufacturing relates to its complex, multi-product nature. But, according to the researchers, each of these electricity-driven pathways supports chemical industry decarbonization for various feedstock choices and end-of-life disposal decisions.

Regardless of the pathway chosen, the researchers stress the need for active research and development and deployment of these technologies. They also emphasize the importance of workforce training and development running in parallel to technology development.

New industry partnerships

While DC-MUSE has made strides in decarbonization research, truly transformative progress will require more extensive and deeper partnerships with industry leaders. As the researchers continue their work in developing cutting edge technologies, the team has also been busy conducting outreach to potential partners in the industry.

Early this Fall, the DC-MUSE team gathered members of the industry, including big names from the pharmaceutical and energy sectors, to gather ideas and assess industrial needs. One initiative is to establish an NSF Industry-University Cooperative Research Center (IUCRC) to develop an industry-driven research portfolio with the goal of catalyzing the decarbonization of the chemical sector.

“We need to work together with industry to identify the most beneficial path for decarbonization,” says Simon Mashala, Center Managing Director. “Especially for American companies, investments in long-term decarbonization strategies have not been substantial. In Europe, where consumers tend to be more unforgiving of companies who harm the environment, the industry has a head start. For America’s chemical sector to maintain its competitiveness, big changes need to be made.”

“Robust investments in long-term decarbonization solutions can ensure the future of the sector, and that’s where partnerships with DC-MUSE can transformationally change the outlook of the industry,” he adds.

Industry-university collaborations have enormous potential to accelerate innovation and deployment of decarbonization technologies

The NSF IUCRC program provides a structure for academic researchers to conduct fundamental, pre-competitive research of shared interest to industry and government organizations. Participating organizations pay membership fees so that they can collectively envision and fund research, with at least 90 percent of member funds allocated to the direct costs of shared research projects.

For DC-MUSE partners, the benefits they receive include accessing knowledge, facilities, equipment, and intellectual property in a highly cost-efficient model; leveraging Center research outcomes in their future proprietary projects; interacting in an informal, collaborative way with other private sector and government entities with shared interests; and identifying and recruiting talent. DC-MUSE is currently in the process of recruiting members, who will be able to get in on the ground floor of the opportunity.

Industry-university collaborations have enormous potential to accelerate innovation and deployment of decarbonization technologies. When academic researchers and company scientists work closely together, they can better understand real-world problems and constraints. And research can be rapidly translated into commercial solutions. However, these partnerships have been lacking in the decarbonization space. DC-MUSE aims to change that through collaborative initiatives like the NSF IUCRC.

A school-wide commitment to sustainable engineering

While DC-MUSE is a collaboration between multiple institutions, its heart is at NYU Tandon. And NYU Tandon has created a space where sustainability infuses a large portion of the work produced there.

For example, in 2022 Miguel Modestino was named the director of a new Sustainable Engineering Initiative (SEI) at NYU Tandon, which is devoted to developing comprehensive and tangible engineering methods of addressing the vast array of environmental challenges now facing the world.

Modestino, the Donald F. Othmer Associate Professor of Chemical Engineering, is himself a member of DC-MUSE, and Taylor is a member of the Sustainable Engineering Initiative. The initiative’s researchers, who include faculty across multiple departments, will be focused on a framework they call AMRAd: avoiding emissions and pollutants whenever possible; mitigating them when total avoidance isn’t possible; remediating in cases where mitigation is insufficient, such as when dealing with situations that developed before 1970s-era environmental protections were put into place; and, finally, developing engineering adaptations to situations beyond human control, such as when localized flooding occurs, almost inevitably carrying contaminants.

While still new, the initiative is ramping up its activities. It currently has multiple openings for faculty members and researchers to join the team, and new lab spaces are being set up in order to accommodate the new research.

Modestino and the other researchers involved are applying the framework to a variety of areas, such as clean transportation, industrial decarbonization, efficient and resilient power grids, disaster risk analysis, environmental justice, and others.

While still new, the initiative is ramping up its activities. It currently has multiple openings for faculty members and researchers to join the team, and new lab spaces are being set up in order to accommodate the new research.

Beyond research, SEI has a strong educational platform. An interdisciplinary team of faculty members, led by Professor Ingrid Paredes, have started to integrate sustainability into the first-year engineering curriculum at NYU Tandon, including General Engineering, mathematics, physics, expository writing, and more. Even something as simple as framing exam questions as sustainability problems can help recruit these young engineers into tackling some of the planet’s most stubborn issues.

“Engineering decisions are not made in a vacuum — they are shaped by and can shape our environment, and that is a responsibility that our engineering community holds,” says Paredes. “We hope for our students to understand this responsibility early in their academic years, and to consider sustainability as a key part of engineering design processes.”

Beyond the School, Modestino has been establishing connections with local green-tech industries. AIR COMPANY — a Brooklyn-based company that uses CO2 to create sustainable chemicals and fuels that can be applied to a variety of consumer and industrial products — now has access to a wet laboratory incubation spaceon campus. And the Initiative has brought in local entrepreneurs to teach Tandon students about how to create and support startups in the green tech space.

“We hope to have many other sustainable engineering companies joining us in the future, since we have truly unique facilities and a vibrant innovation ecosystem to offer them. With enhanced industry-university collaboration, rapid progress can be made. It’s time for more companies to partner with academic initiatives like DC-MUSE and SEI to decarbonize chemical manufacturing and build a sustainable future,” Modestino says. “Ultimately, our goal is to forge fruitful collaborations and help New York City become a global cleantech innovation hub.”