With the summer heat and rainy flood season now prevalent worldwide, the complex weather challenges the safety management of charging stations. So how should the administrator maintain the EV charging station? Don’t worry; using this guide can solve all your doubts.

Regular cleaning

Ensuring normal heat dissipation from the EV charging station is crucial in maintenance in the hot summer environment. Pay attention to the side dust screen to ensure that no foreign objects are blocking the air ducts of the air inlet and outlet to ensure good ventilation. Regularly clean the surface of the charging station to ensure that the surface is free of foreign matter, and the cleaning cycle is once a week. Regularly do dust cleaning or replacement work on the dustproof cotton of the air inlet once a month.

Error example, the air inlet not cleaned for months and covered with an ash layer of anti-dust cotton will block the air inlet and outlet, affecting the normal heat dissipation of the equipment.

In the summer, maintenance also needs to give the charging module regular dust cleaning to ensure the module’s cooling effect. It should be noted that the module should be placed horizontally after taking it out. Please do not place it vertically on the ground to avoid the module falling and the connector damage at the bottom of the module.

Gateway Maintenance

The gateway does not have a waterproof function and cannot be placed directly in the outdoor rain or wet place to use. The gateway must be placed in the distribution box, which can play a protective and anti-theft role. The surface of the gateway should be kept clean, and the surface of the gateway should be cleaned regularly to avoid dust and metal dust from entering the gateway’s interior and affecting the equipment’s operation.

Connector Maintenance

Summer is the season of the high incidence of stormy weather; pay attention to keeping the connector dry. After the end of charging, the connector must be inserted back and confirmed into place to avoid dropping and causing damage to the connector; a timely connector return can also avoid the connector pins exposed to the air to prevent the accumulation of dust and water damage and other foreign objects into the connector caused by the safety hazard problem.

Regularly check if the connector is clean and clear, and ensure there is no dust and sediment residue inside. The inspection cycle is a daily inspection. Before charging, we need to check whether the electric vehicle charging interface is clean and clear and confirm that there is no dust, sediment residue or scorch marks inside the interface. If there is any abnormality above, it is recommended to ask the driver to go for maintenance and cleaning before charging.

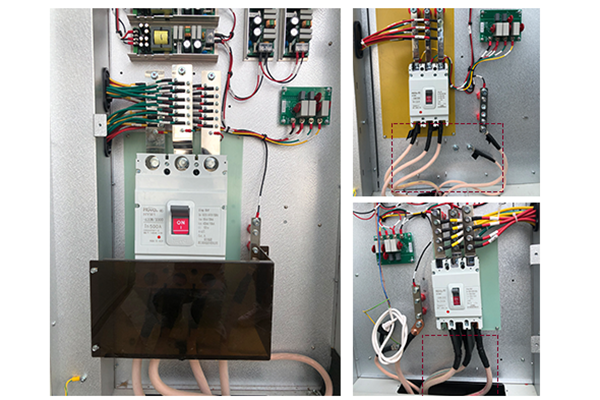

Power line inspection

The high temperature in summer makes the power cord prone to damage. Therefore, during maintenance, it is necessary to check whether the power line in the charging pile is grey, black or yellow and whether it has poor contact, ageing or looseness. It should be noted that the power line should be checked with power off and avoid working in the energized state.

It is important for charging station operators to implement standard maintenance to provide a better charging experience for customers and extend the equipment’s life. In addition to regular daily inspections, charging station managers need to pay attention to gateway maintenance, surface cleaning and maintenance, connector homing and cleaning, and power cord troubleshooting in their daily work. If you have any questions, please contact SETEC Power’s after-sales team for a consultation.