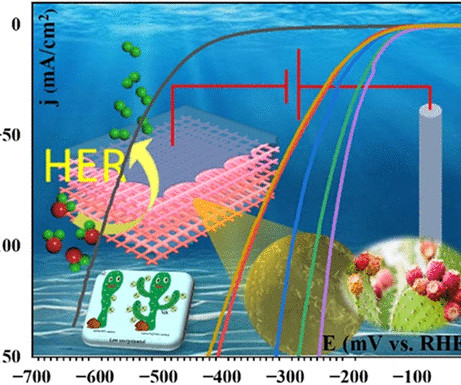

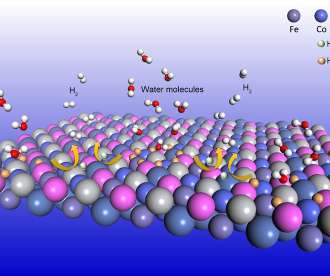

UT El Paso-led team designs cactus-inspired low-cost, efficient water-splitting catalyst

Green Car Congress

MAY 16, 2023

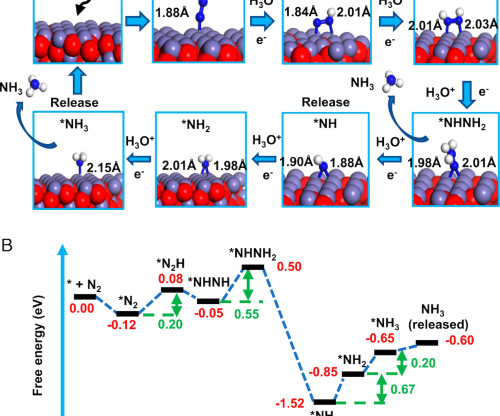

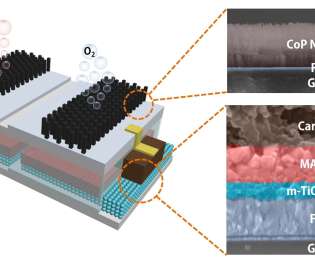

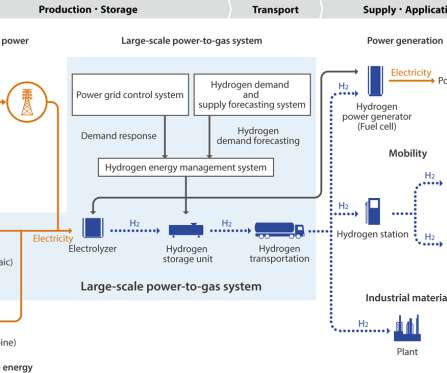

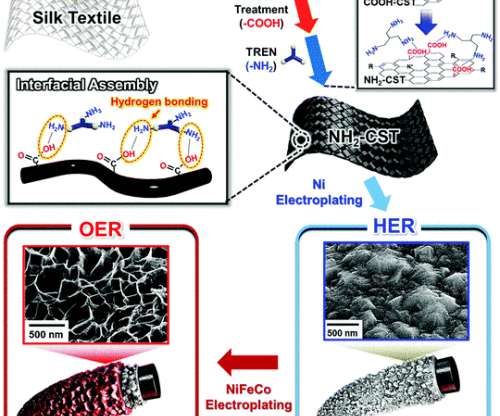

Researchers led by engineers at The University of Texas at El Paso (UTEP) have proposed a low-cost, cactus-inspired nickel-based material to help split water more cheaply and efficiently. Nickel, however, is not as quick and effective at breaking down water into hydrogen. who led the study.

Let's personalize your content