Aqua Metals successfully recovers cobalt and manganese in Li-ion recycling pilot

Green Car Congress

JUNE 30, 2023

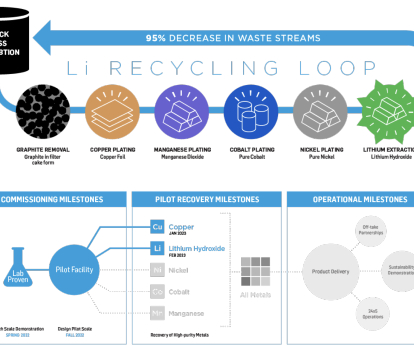

Aqua Metals, a developer of sustainable lithium-ion battery recycling, announced the successful completion of its Li AquaRefining recycling pilot; transition to 24/5 operations; and production of high-purity, saleable quantities of sustainably recycled battery materials. Earlier post.)

Let's personalize your content