MFE Magnesium For Europe GmbH was founded in 2021 to establish a clean, green and competitive magnesium production in Kupres, Bosnia-Herzegovina, Europe.

Magnesium (Mg) metal is a unique, strategically important, and critical raw material for many downstream industries such as aircraft, vehicle, and steel manufacturing and notably aluminium (Al) alloy production. No substitute materials can rival Mg’s powerful combination of light weight, sturdiness, and relatively low cost.

At present, the European industry is entirely reliant on Asian primary Mg supplies. Another challenge for Europe’s Mg-consuming industries is the increasing pressure on them to become climate-neutral and the relatively large CO2 footprint of conventional magnesium production.

Fortunately, there is a solution in sight. About two decades after European Mg manufacturers closed their unprofitable plants, MFE is pioneering the re-establishment of a clean, green, and sustainably competitive Mg production in Europe.

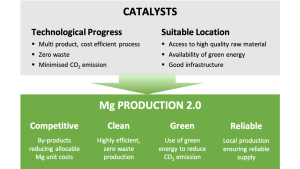

MFE’s project is motivated and facilitated by two important catalysts:

- Progress in Mg manufacturing technology; and

- An advantageous location where MFE has control over and access to a high quality dolomite deposit with up to 100 million MT proven and probable reserves of raw material, ownership of a suitable production site close to the deposit, good infrastructure, and access to an abundance of low-cost green energy (hydro, wind, photovoltaic).

The two catalysts pave the way for a cleaner, greener, and more efficient Mg manufacturing – European Mg production 2.0.

Benefitting from technological progress

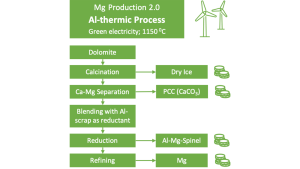

MFE will use the Aluminothermic (Al-thermic) process for its future production, a fully established Mg production process with a Technology Readiness Level of eight to nine. The Al-thermic process constitutes a quantum leap in magnesium production regarding efficiency and environmental friendliness. It is a further development and a combination of the conventional Pidgeon process and the Magnetherm process used by Alcoa for about 50 years and until the beginning of this century.

The Pidgeon process, which extracts Mg from calcined dolomite in a vacuum at high temperatures with ferrosilicon as a reducing agent, has been the gold standard of Mg production for over half a century, particularly in China. However, the process has been attracting increased criticism for its high energy use (also in connection with the required ferrosilicon production), the resulting slag as a waste product, and the emission of substantial amounts of CO2 (c. 20-25 tonnes per tonne of Mg), especially where coal-generated gas and electricity is used to power the process.

The development of the Al-thermic process involved three critical changes: The insertion of a process step where calcium and magnesium are separated, the use of Al-Scrap (or pure Al) as reductant, and a slightly lower operating temperature of 1150°C instead of 1250°C. In summary, these three seemingly minor differences make for a radically different result:

- Highly efficient conversion of dolomite into four sellable products: Mg and Mg-Alloys, PCC (Precipitated Calcium Carbonate), Al-Mg-Spinel, and dry ice — four products with substantial market value and deep markets across Europe and thus lower unit costs allocated to each ton of Mg produced; and

- No waste material and, therefore, no waste disposal cost.

MFE will power its Al-thermic Mg production plant with green electricity (hydro, wind, photovoltaic). By using Al-scrap as a reductant and with its multi-product output, MFE will be able to produce Mg with a carbon footprint of less than one ton of CO2 per one ton of Mg and about twelve tons of by-products (as determined by DLR, the external LCA auditor acting on behalf of MFE).

MFE is in the final stages of an industrial scale test using its Kupres dolomite in an Al-thermic pilot plant. The test and the process have been audited by DMT (TÜV Nord), and the final test results will be available in April 2024.

Advantages of Kupres, Bosnia-Herzegovina, as a production location

The other factors required for a clean, green, and competitive Mg production are to be found in the specific characteristics of MFE’s production location. These include:

- Access to a high quality and sufficiently large proven and probable dolomite raw material source;

- Access to vast amounts of green electricity to power the production;

- A large production site sufficiently close to the dolomite deposit;

- Reliable infrastructure, educated workforce, and political and legal stability; and

- Proximity to large clients (mainly for the by-products with a limited catchment area).

Bosnia-Herzegovina (BiH) is part of the Western Balkans and strategically well positioned with its proximity to the EU and the Adriatic Sea. In December 2022, the EU unanimously granted BiH EU candidate status. Since 2013, duties, visas, and trade restrictions for industrial products have largely disappeared between BiH and the EU. MFE’s raw material, the production site, and all relevant utilities are located in Kanton 10, the very Western and Croatian-speaking part of BiH, and less than 150km away from the industrial port of Ploce, the major deep-water gateway for goods shipped to and from the Balkans.

The Grguljaca mine from which MFE will source its raw material covers an area of ~9.5 ha (23.5 acres) with ~11 million MT of mineable dolomite, sufficient to feed a 15kt p.a. Mg production for over 50 years. An additional adjacent deposit s.t. exploration covers a further ~47.5 ha with enough raw material to run a 50 kt p.a. Mg production for over 75 years. DMT (TÜV Nord) has audited the deposit twice (PERC resource and PERC reserve audit report). The deposit in Kupres is one of the highest quality dolomite deposits currently known in Europe.

Kanton 10 is generating green electricity only (so far mainly hydro and wind power) and is a net exporter of green electricity. The Kanton’s topography and weather are extremely favourable for hydro, wind, and solar power generation. As a result, a substantial ramp-up of further wind farm capacity is planned for the next decade, warranting an ample supply of green electricity for MFE’s production.

Multi-product output for sustainable competitiveness

Combining the Al-thermic process and MFE’s specific location advantages will make for a diversified revenue base and improved economics, ensuring MFE can offer Mg, Mg-alloys and the three by-products at competitive prices.

Whilst Mg prices have historically been very volatile, prices for the by-products are much more stable and predictable, particularly if the products are of high quality. At current market prices, the combined sales value of the by-products covers most of MFE’s forecast production cost. Consequently, MFE’s ability to tolerate price fluctuations in the Mg and Mg-alloy markets is expected to be very high.

In terms of cost control, MFE’s project is also unique. Besides long-term price and supply stability for the raw material, MFE is investigating the possibility of building its own wind and solar park near the production site, thus relying much less on the local grid for its electricity supply. Furthermore, the reductant, the second largest cost item in the production process, can be hedged short- to medium-term. In contrast to ferrosilicon, aluminium is quoted on the LME; therefore, the price of Al (and Al-Scrap) can be much better managed.

MFE’s project is close to implementation readiness

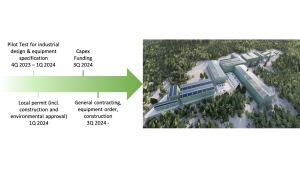

MFE is in the final stages of the preparation and planning phase, with only three tasks left to finalise:

- Completion of the industrial scale pilot test to optimise industrial design and equipment specification;

- Receipt of a local permit comprising of general construction approval and environmental permit; and

- Organisation of ~$80m-$200m capital expenditure funding, subject to the degree of backward integration, consisting of equity and debt.

Following the successful completion of the above, MFE will proceed with general contracting, equipment order, and construction in Q3 2024. MFE is in the process of signing a letter of intent with an experienced contractor and operator who will also commission MFE’s Mg production facility.

MFE is grateful for the support that it has and will receive from numerous stakeholders and is looking forward to a cleaner, greener, and more competitive European magnesium production future.

Please note, this article will also appear in the seventeenth edition of our quarterly publication.