As the energy transition and electrification of mobility drive the explosive demand for batteries, Christophe Mazeaud, director of Battery Industry Solution, Siemens Digital Industries Software, discusses the key role that a holistic quality program plays in scaling and stabilizing battery production.

What we are seeing across the battery manufacturing landscape is an extraordinary drive to meet unprecedented demand, and this environment makes digital solutions essential to achieving quality, cost, volume and delivery targets. Quality management is at the heart of these efforts. Only a digital manufacturing solution that integrates a quality culture throughout the design and manufacturing cycle enables cell, module and pack manufacturers to efficiently scale and stabilize production in this highly challenging marketplace.

Market trends and manufacturing challenges

The rapidly increasing demand we are seeing for batteries is propelled largely by climate-driven market forces, including accelerated production of electric vehicles and energy storage solutions, as well as diverse financial incentives from governments across the world. These governments hope to encourage local development of gigafactories (plants with annual production capacity measured in gigawatt-hours) and to reap the economic windfall that would follow.

In response, manufacturers are entering the battery market in large numbers, leading to greenfield factory development in nearly every global region and refurbishing factories by existing battery makers and automotive OEMs. These developments lead both to price pressure and to the need for continuous product innovation and process improvement. Under such conditions, it is challenging for new and experienced manufacturers alike to produce high-quality batteries profitably and at scale.

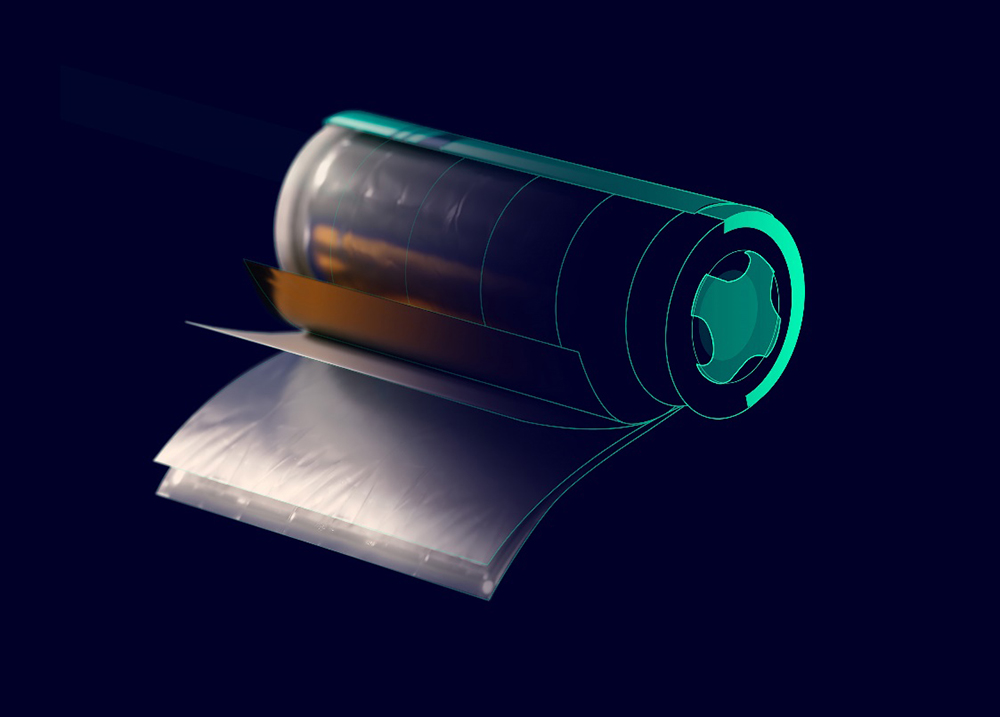

Three primary characteristics of today’s battery industry contribute to this challenge. First is the newness of the industry. The microstructure and chemical composition of battery materials have a considerable impact on quality and battery performance, and the interdependencies of materials and processes along the value chain are not yet well understood. Additionally, comprehending the interdependencies is a moving target, with fast-paced product and process innovations constantly underway as battery manufacturing matures. Technological newness makes it difficult for both startups and incumbent companies to set control parameters in the battery production process.

The second challenging characteristic of the industry is the need for scalability. A battery production ecosystem, whether newly built or an existing factory, must be capable of scaling rapidly without undermining battery quality. With the exponential growth in battery demand, all manufacturers must quickly ramp up production of each line, often while building multiple lines and factories in parallel. This challenge is compounded for startups who are also growing their organization at the same time.

Third, compliance with stringent and quickly evolving regulations requires a high level of traceability through three distinct kinds of manufacturing: batch, continuous and discrete processes. In this regard, greenfield companies have an advantage over incumbents. They can turn this challenge into an opportunity by setting up the correct information technology/operational technology (IT/OT) landscape, right from the beginning. Traceability can then be supported through seamless connections across digital platforms.

Building better batteries faster by leveraging innovative and advanced digital solutions from battery design to battery manufacturing

Siemens Digital Industries Software is collaborating with battery manufacturers as they develop innovative manufacturing solutions to address these challenges. Through these collaborations, we have realized the importance of digital manufacturing solutions for accomplishing high-volume, high-quality battery production. If companies are to control and document end-to-end quality while also managing the complexity, innovation, and rapid scale that characterize today’s battery manufacturing ecosystem, they must figure out how to accelerate battery production through the whole product lifecycle and implement a smart manufacturing strategy.

Delivering high-quality batteries requires you to manage different processes across the whole product lifecycle, from new product development to mass production. It is essential to design with a quality mindset to accelerate battery production. Quality engineers can leverage engineering data, such as 2D or 3D models, to acquire relevant information or perform tolerance evaluations, and the project quality can be monitored and approved in respective milestones. Risks can be identified, assessed, and mitigated in the virtual product and process structures, and residual risks can be managed through a control plan.

By “smart manufacturing” we mean a digital strategy that encompasses the entire manufacturing process, from battery design and factory floor optimization to streamlined orchestration of manufacturing operations, to fast, accurate sampling and testing. Smart manufacturing fully integrates all digital systems to drive quality and efficiency throughout the battery manufacturing process. To manage the fast pace of battery innovation, a fully integrated digital approach helps capture knowledge gained as each new material or process is brought into production. Manufacturing insights developed from this captured knowledge can be used to improve the next product run and reused on the next battery generation.

We have developed the Siemens Accelerated Battery Development and Smart Battery Manufacturing solutions purposefully to help battery companies achieve manufacturing efficiency, readiness and excellence. This is accomplished through integrated and standardized machines, processes and systems; virtual multidisciplinary planning and simulation; and connected, automated and continuously monitored lines.

Reaching quality excellence with a closed-loop quality management solution

In a digitalized ecosystem for the battery industry, the quality culture needs to be at the heart. Siemens solutions orchestrate consistently processes throughout the three major phases of battery development and production: (1) design and planning, (2) execution and control, and (3) continuous improvement.

Design for quality and quality planning—From the very start of product development, battery designers must apply quality guidelines and standards from the automotive or other end-user markets. Shifting left, designers and engineers must sort out problems in the virtual realm rather than discovering them on the manufacturing floor. With Siemens closed-loop quality management solutions, product, manufacturing and quality engineers work concurrently in the same digital environment, leveraging digital models from each other’s efforts. For example, design failure mode and effects analysis (FMEA) are built from the engineering bill of materials (eBOM). Product manufacturing information (PMI) includes 3D models, which serve as the starting point for quality control plans. Many other collaborative tasks benefit from the fully integrated digital solution.

A closed-loop quality management solution automatically maintains the traceability of changes, evolutions, and engineering decisions, which is of great benefit to the entire battery engineering team. Using this solution, the team can maintain the quality deliverable up-to-date and in sync with the requirements and engineering changes with significantly less effort.

Quality execution and control— As part of the depicted comprehensive flow, two other systems within the smart manufacturing solution for batteries execute the virtually defined control plans digitally. These are the manufacturing execution system (MES) and the laboratory information management system (LIMS). This holistic digital approach enforces preventive quality practices, avoiding human errors and getting the production line quickly to a stable quality level.

For the battery factory to reach the next level of quality and perform predictive quality control, data analytics capabilities within the smart manufacturing solution combine process parameters, image processing, product performance controls and environmental context, and leverages machine learning algorithms. Ultimately, the goal is to reach the prescriptive quality level. Securing product quality at this level involves injecting data analytics into simulation models deployed at the edge to calculate and apply corrective actions on-the-fly.

Continuous improvement – Of course, defects or nonconformances (NCs) cannot be completely avoided with strong planning or eliminated with constant production process monitoring. Instead, a smart manufacturing solution efficiently manages nonconformances and enables fast reaction as well as continuous learning. Nonconformances are captured digitally and treated immediately at the shopfloor level, whether they are detected through incoming goods inspection, in-line inspections or offline laboratory quality control testing.

When required, certain quality issues are escalated to the engineering domain to trigger a proper root cause analysis. Within Siemens digital threads, the problem-solving process occurs in the same collaborative platform as product design, manufacturing planning and quality engineering. Full integration allows centralized management of issues and actions, as well as an intuitive identification of the required improvements, in any domain at the enterprise level.

Not only quality issues are treated quickly, but actions are also taken immediately to prevent recurrence. Lessons learned are captured for the benefit of all departments and factories. The result is truly continuous quality improvement.

Benefits within the battery manufacturing plant and beyond

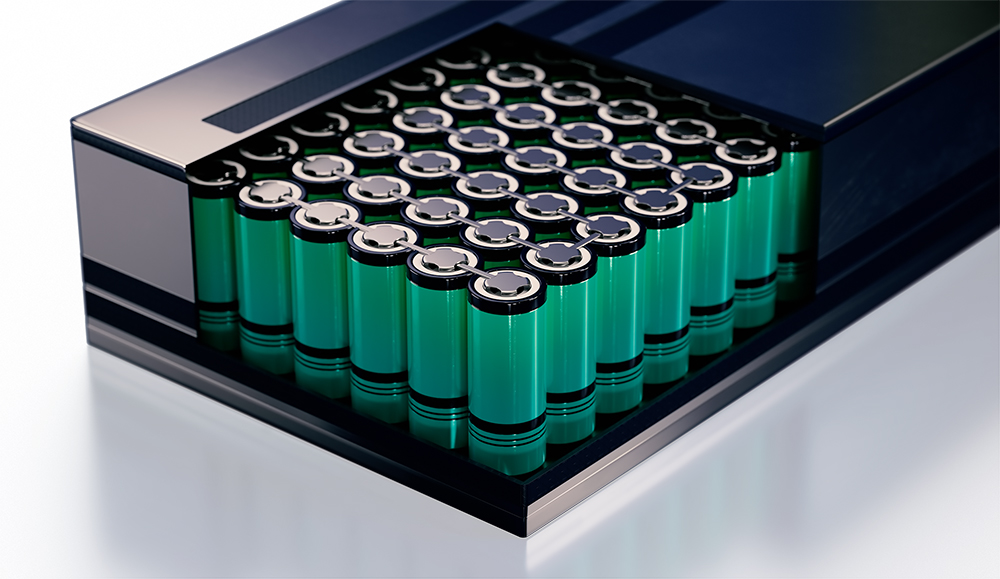

Efficiently scaling and stabilizing the production of battery cells, modules and packs is the goal and primary benefit of Accelerated Battery Development and Smart Manufacturing solutions with a closed-loop quality approach.

Other direct benefits for the battery maker include:

- Minimize costs of poor quality thanks to continuous improvement throughout the whole product lifecycle

- Faster time to market and scale-up thanks to cross-domain collaboration in a quality-driven product development

- Start compliant and stay compliant, with traceable, auditable and model-based quality processes

There are compelling business cases for digital transformation and quality management in this rapidly growing and evolving industry. Siemens Accelerated Battery Development and Smart Manufacturing solutions with closed-loop quality management accelerate the adoption of intelligent, efficient, and adaptable battery development and production processes. This digital technology enables development centers and factories to manufacture battery cells, modules, and packs that meet quality, throughput, cost, and sustainability goals. The insights acquired from both design and operational data allow for continuous improvement and increased agility. These capabilities empower battery manufacturers to secure a dominant position in this expanding industry.

Siemens closed-loop quality management solutions go beyond the traditional paradigm of the company itself, reaching out to the extended enterprise. The solutions strengthen upstream supplier collaboration and downstream assessment and monitoring of core quality processes. These close ties with suppliers and auditors are critical, especially as the battery industry incorporates frequently updated quality standards and innovates cell chemistries and formats, new materials and next-generation sustainable technologies.

Learn more about Siemens Battery Smart Manufacturing solutions.