Ford is experimenting with auto part prototypes made from olive tree scraps.

Ford engineers in Cologne started researching the possibilities of using food waste to create auto part prototypes. They found that pruning olive trees created 7 million tons of waste every year and thought it would be an excellent material for their experiment.

“One major benefit is that these fibers are usually waste. They are not used for anything else,” said Ford Project Lead Inga Wehmeyer. “And so we don’t have any additional land usage or water consumption to grow these fibers.

Ford recycled and repurposed olive tree scraps from Andalusia, Spain—a region with the highest production of olive oil in the world. Their research led to the COMPOlive project, which yielded auto part prototypes that were durable and lighter.

Ford engineers also reduced the amount of plastic in vehicle parts and its carbon footprint through the COMPOlive project. The prototype car parts from the project were made of 40% olive tree fibers and 60% recycled polypropylene plastic.

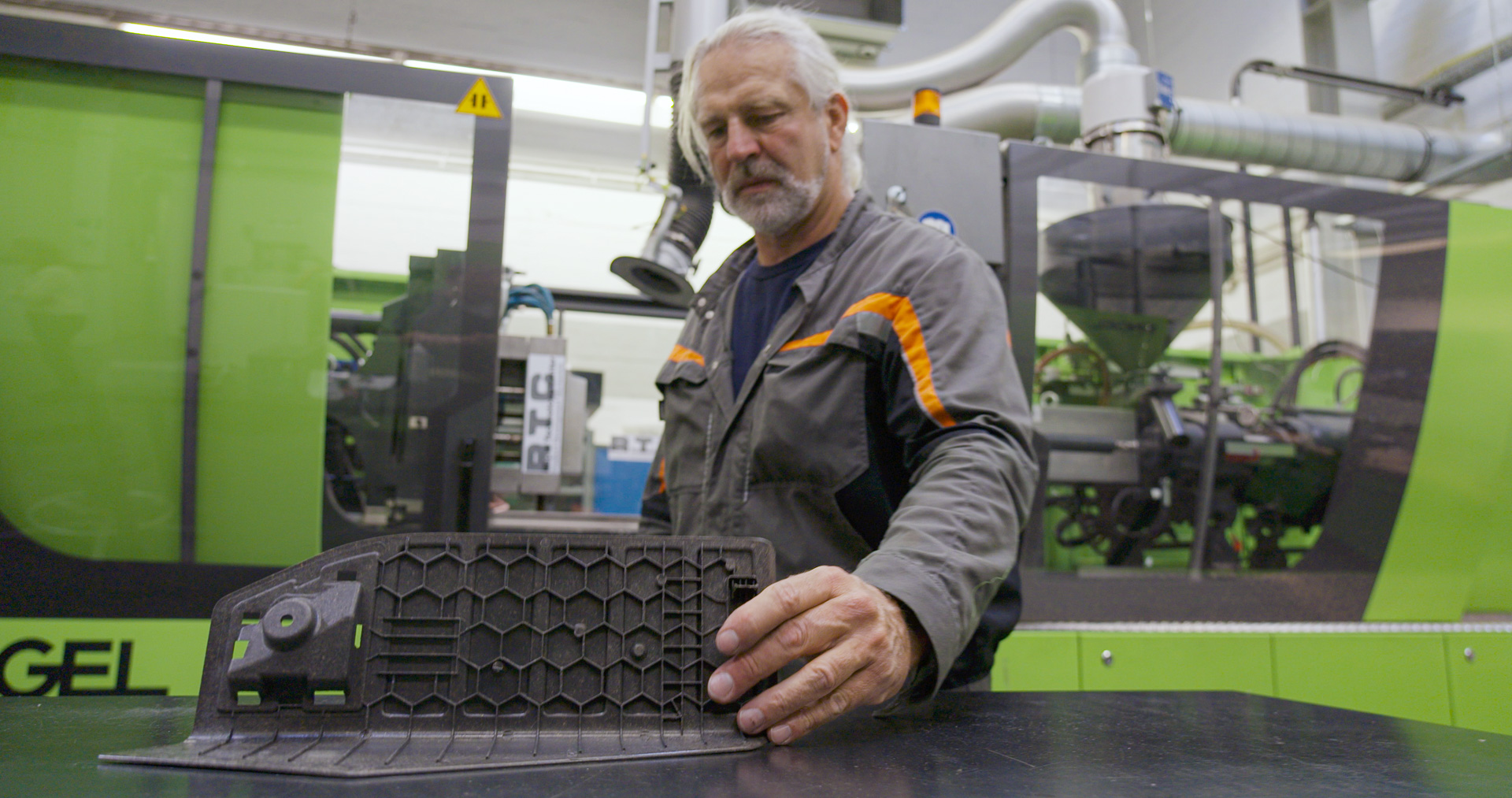

In a Ford video, Inga showed a footrest made out of olive tree waste for the Ford Focus. She noted that Ford was able to test the footrest under real conditions.

“The tests that we did, the simulations showed that this material is very capable of being used in our cars,” noted Thomas Baranowski, an injection molding expert.

Ford is no stranger to using food waste in auto parts. For was one of the first automakers to use soybean-based foam seats and headrests. The legacy OEM also incorporated used yogurt cups for the Ford Mustang Mach-E frunk insert. It also uses recycled ocean plastic in the Ford Bronco Sport’s wiring harness clips.

If you have any tips, contact me at maria@teslarati.com or via X @Writer_01001101.