Innovation in the battery industry is crucial to the large-scale rollout of electric vehicles, and the development of aluminium cylindrical cell housing is a prime example.

Decarbonisation of transportation and industrial processes is one of the central challenges for humanity related to the 1.5°C target ratified in the Paris Agreement in 2015, which will require a massive increase of energy storage capacity. The vital role of lithium-ion battery (LIB) cells in future mobility concepts results in an anticipated demand in Europe of about 900 GWh/a in 2030.

Customers desire fast-charging, long range and safe vehicles at low cost. Focusing on these preferences, LIB designers as well as automotive OEMs aim to bring down cost on the one hand and increase energy as well as power density and safety of LIBs on the other hand, while pushing charging rates towards conventional refuelling times.

Targeting larger cell formats

The battery industry is targeting larger cell formats, which enable simplified module design and cell-to-pack or even cell-to-chassis solutions.

In this regard, hard case battery cells and in particular cylindrical cells will play an important role in enabling the named developments. Tesla’s announcement of a tabless 4680 cylindrical LIB has triggered a revival of cylindrical cells in the automotive industry. While the increased cell size provides several benefits, thermal management becomes more challenging. Larger cell dimensions lead to decreased surface area for heat dissipation in proportion to the cell volume and affect the rate of conductive heat transfer from the cell core to the cell housing.

While Tesla tackles this challenge with the tabless design and a crimping process, we have identified an alternative or complementary approach to overcome the drawbacks in thermal properties of 4680 sized LIBs, while simultaneously boosting their fast-charging performance and lifetime.

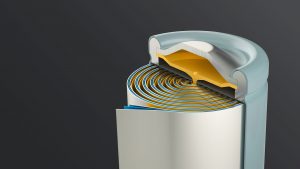

Within our concept study we have designed a cylindrical LIB in 4680 format, comprising an aluminium cell housing and compared it to a reference LIB cell with commonly used nickel-plated steel housing. To develop the concept cell, we considered the following design challenges:

- Tailoring an aluminium based cell housing material, which enables highest safety, performance and sustainability standards.

- The mechanical integrity of the aluminium cell housing was designed to be comparable to a nickel-plated steel housing resulting in an increased wall thickness.

- The jelly roll was turned upside down and the anode tabs were connected to the cap featuring a copper CID insulating the anode potential from the aluminium cell housing to avoid reactions of lithium and aluminium.

- The number of tabs, their dimension and positioning were designed to realise current densities and heat generation per volume comparable to 21700 high energy automotive cells.

Both versions of the cell were subsequently integrated into a thermal simulation model to evaluate their performance during fast-charging of constant current of 3°C, considering two cooling system concepts: Bottom plate and sidewall cooling.

Our design study reveals that aluminium cell housings are feasible for 4680 format cylindrical LIBs and provide several benefits compared to nickel-plated steel housings. On this basis we anticipate that an aluminium cell housing enables significant improvements of the fast-charging performance of large cylindrical LIBs such as the 4680 cells. At the same time, our ION cell design ensures feasibility of high recycled content and a low carbon footprint, while fulfilling all required specifications of state-of-the-art LIBs in terms of mechanical strength, good formability, weldability as well as electrolyte compatibility. The benefits of an aluminium housing perfectly fit the requirements of high energy and high-power density LIBs for electric vehicles (EVs).

However, the cells improved power capability also make it a good fit for power tools, while the superior gravimetric energy density could make LIBs featuring an aluminium cell housing an attractive solution for aircraft applications.

Material design for cylindrical LIB cell housings

Aluminium combines low density with excellent electrical and thermal conductivity, as well as high formability while maintaining good rigidity.

For state-of-the-art prismatic LIB cell housings as well as for pouch bags these properties are crucial and aluminium is the established industry standard. However, cylindrical LIB cells are traditionally equipped with heavier and less conductive nickel-plated steel (NPS) housings.

Larger LIB cell formats such as 4680 and the resulting challenges in the thermal management of the cells require significantly improved heat conduction as well as reduced internal resistance of the cells. Thereby, the low thermal and electrical conductivity of NPS become limiting factors. In this context, LIB cell housings made from aluminium alloys featuring about four times higher electrical and about three times higher thermal conductivity can help to overcome these challenges.

The material design for cylindrical LIB cell housing goes beyond conductivity

The following properties are vital for a successful application and are the basis of Speira ION cell:

- Strength: Competitive volumetric and gravimetric energy densities require high strength materials to keep the wall thickness as low as possible while maintaining highest safety standards.

- Chemical electrolyte compatibility: To give no chance to corrosion, cell housings must be resistant against chemical reactions with the electrolyte.

- Formability: High limiting drawing ratios and controlled earing are key to enable efficient cup drawing without excessive tooling costs or scrap generation and to a reliable forming operation.

- Weldability: Cell manufacturing can include ultrasonic and laser welding during tab welding and cell interconnection. Also lid designs and cell sealing operations may require laser welding.

- Sustainability: Battery and automotive industry target minimal greenhouse gas emissions and waste generation. Hence, cell housing materials must be designed for high recycled content and reliable closed-loop concepts. Speira Ion cell for cylindrical cell housings enables up to 80% recycled content.

Ion cell

Our ION cell exhibits a yield strength >250 MPa, electrolyte compatibility and laser weldability comparable to AA3003 H14 – the industry standard for prismatic cells – as well as limiting draw ratios and earing values equal to beverage can body materials. At the same time ION cell enables high recycled content, minimising the CO₂ footprint of the battery cell.

Regardless of the aluminium alloy used, specific design challenges of cylindrical LIB cells, such as aluminium-lithium reactions at the anode potential, need to be considered and overcome. Our approach towards these challenges is addressed in the following sections.

4680 aluminium housing cylindrical cell design concept

To analyse potential benefits of a cylindrical aluminium cell housing, we have developed two versions of a 4680 LIB concept cell.

One design featuring a ION cell aluminium housing and one reference design with NPS housing (reference cell). The final 4680 high energy LIB solution for EVs with a multi-tab arrangement and safety components, as well as the reference cell feature an estimated usable capacity of 23.5 Ah, NMC622 chemistry on the cathode, and graphite on the anode-side. In case of the ION cell, the jelly roll was turned upside down and the anode tabs were connected to the current interrupt device (CID) as part of the lid assembly. Thereby, the anode potential is isolated from the aluminium housing preventing chemical reactions between aluminium and lithium. To achieve high electrical and thermal conductivity and to avoid the challenge of joining dissimilar materials, copper was selected as CID material. However, it should be noted that NPS could be an alternative option.

Large-format cylindrical cells

For large-format cylindrical cells with high energy density, the safety design is of central importance. Our safety design features three independent thermal runaway (a spontaneous chain reaction releasing thermal and electrical energy of cell due to improper cell thermal management, improper loads or internal cell defects) preventing measures – namely CID opening, venting and cap expulsion. The safety measures avoid build-up of explosive gas mixtures within the cell and direct energy towards the top of the cell in case of malfunction or misuse and hence, avoid propagation of a thermal runaway event to adjacent cells.

State-of-the-art LIB cells guarantee a minimum housing burst pressure of 95 bar, while ensuring geometric stability. Therefore, wall thickness and mechanical properties of the housing material must ensure integrity up to that pressure. Based on calculations using Barlow’s and Lamé’s equations and finite element simulations, we have optimised these parameters in our design concepts. As a result, required wall and bottom thicknesses of 0.55mm and 0.65mm for the reference cell housing and respectively 0.75mm and 0.9mm for the ION cell housing design were determined. The outer diameter and the height of our ION cell was increased accordingly, in order to enable direct comparison of the thermal behaviour between our concept cell and the reference design.

Despite its increased wall thickness, the aluminium cell housing features only half as the weight of the NPS housing, which is due to the low density of aluminium. Accordingly, a 9% higher gravimetric energy density is achieved using our ION cell housing, while the volumetric energy density is reduced by merely 2% because of the thicker walls.

The jelly roll concept

Electrode material and geometric parameters of high energy cells were derived from tear downs in literature. Based on cell and jelly roll design, cell capacity, heat generation and heat transfer within the jelly roll were assessed. As commercial 4680 cells are still under development, no validated data that is usually needed for heat-loss evaluation is available in common databases yet. Therefore, we derived reasonable assumptions for the heat generation in a 4680 cell via upscaling available literature and teardown data of 18650 and 21700 cells.

As a result, a multi-tab design featuring six tabs was chosen. Thereby, each of the tabs is positioned accordingly to achieve similar current density per tab and within the cell’s current collectors as featured in 21700 high energy cells.

Want to know more about heat distribution and our improvements in cooling performance? If you want to check out detailed illustrations of the design and our thermal simulations visit www.speira.com/publications/

Please note, this article will also appear in the seventeenth edition of our quarterly publication.