Michigan-based Bollinger Motors has released starting prices for its Chass-E and Chass-E Cab models that could be the basis for a wide range of heavy-duty trucks, including commercial and government purposes.

Coinciding with a presentation from CEO Robert Bollinger at “Work Truck Week,” an event from the National Truck Equipment Association (NTEA), the Chass-E Cab will start at $70,000 in rear-wheel-drive form or $100,000 in all-wheel-drive form. Chass-E models will cost $55,000 with rear-wheel drive or $80,000 with all-wheel drive.

Both rear-wheel-drive models can be made dual-rear-wheel models—“duallies”—for $2,500 extra.

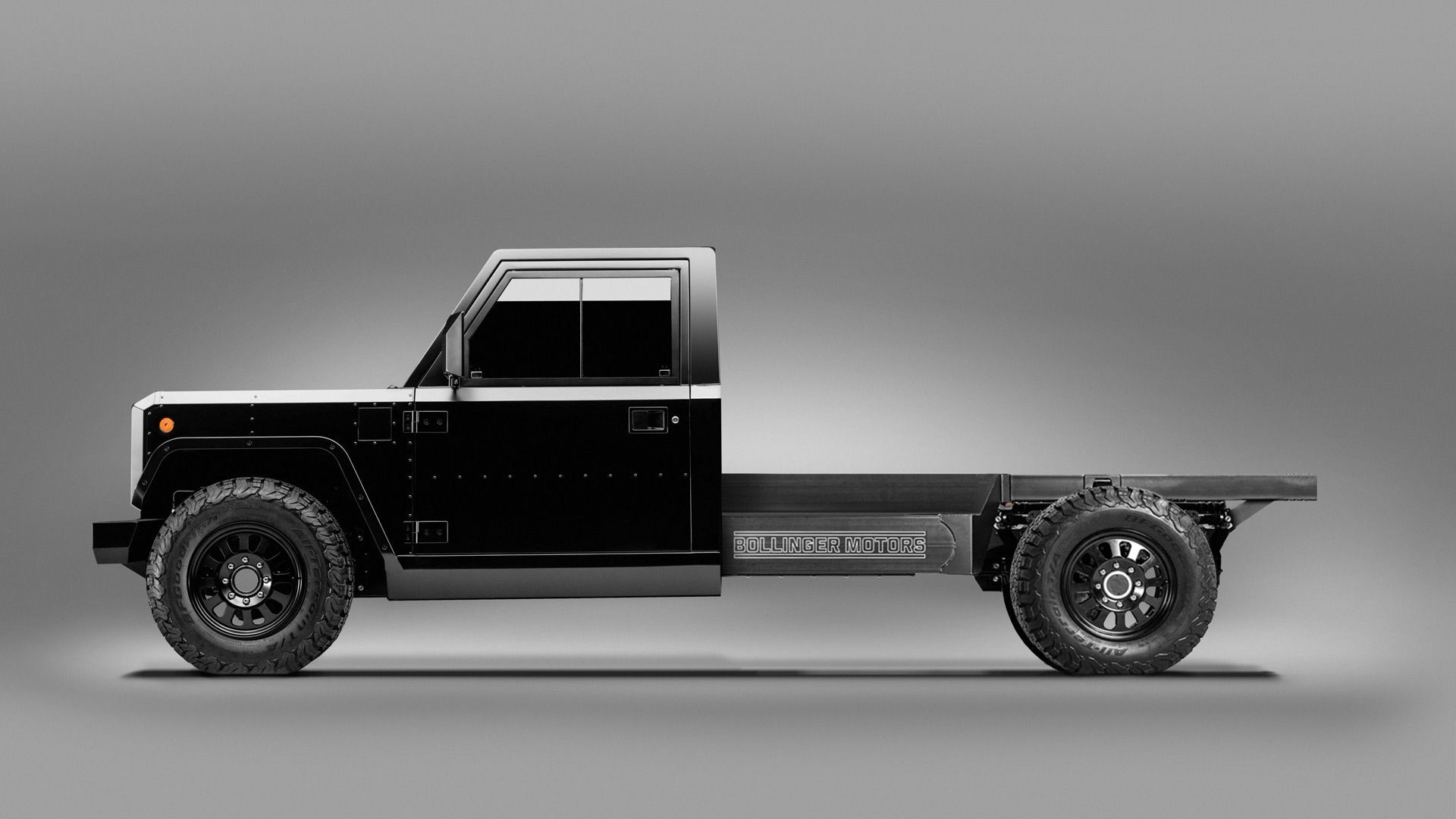

Bollinger B2 chassis cab

Bollinger B2 chassis cab

Bollinger B2 chassis cab

Bollinger is looking for its Chass-E to be used in everything from kit cars and airport tugs to emergency vehicles, while the B2 Chassis Cab might be used for tow trucks, ambulances, and fire rescue. And, of course, it’s what underpins its B1 SUV and B2 pickup.

“There’s nothing on the market, or in development, like our All-Electric Class 3 work trucks,” said Bollinger.

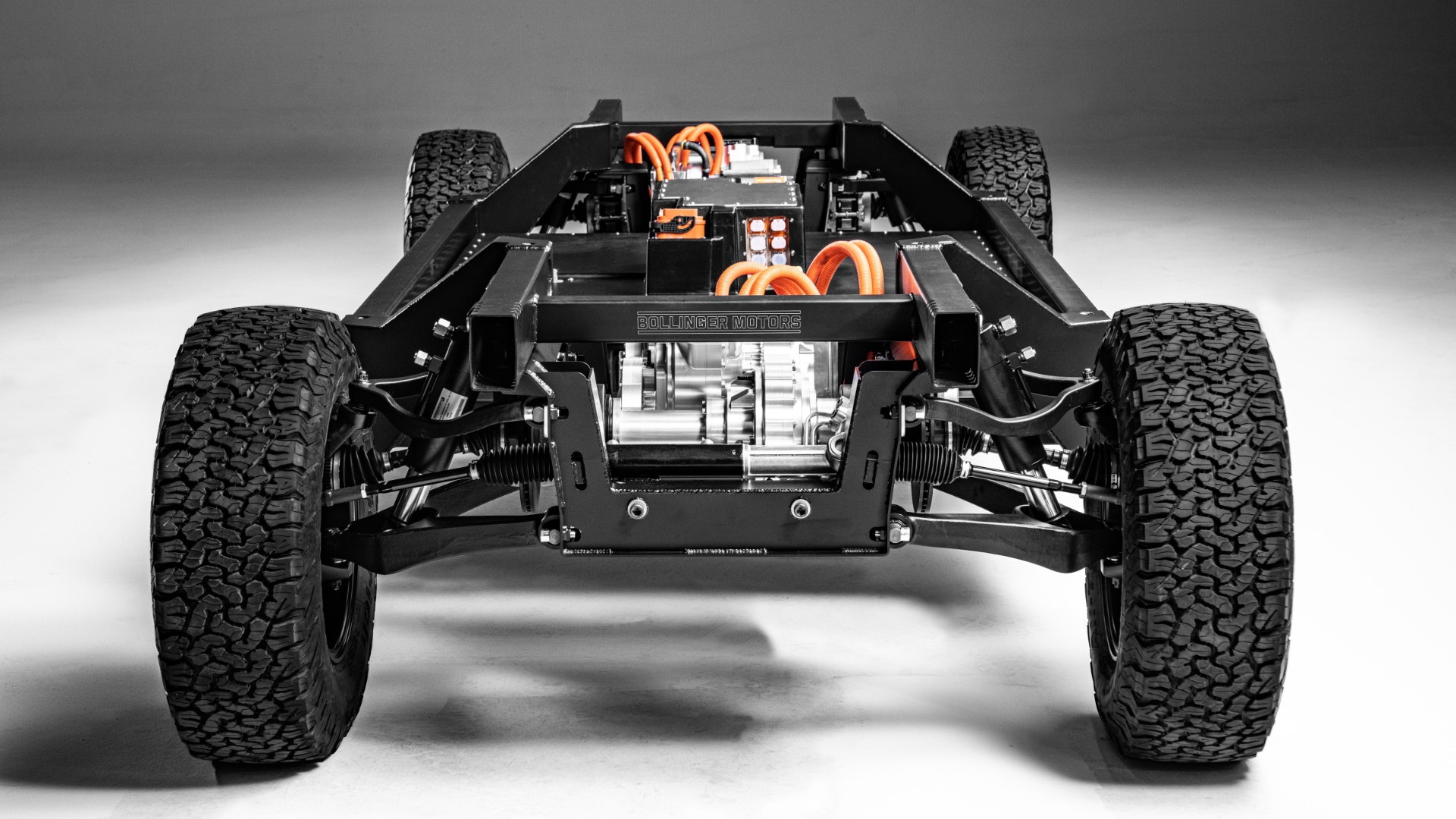

Underpinning the trucks will be Bollinger’s own frame and its own battery pack design. Propulsion units fit on a separate cradle, allowing various differences in power or gearing while the frame can be the same across all trucks.

It offers a hydro-pneumatic suspension, and is capable of hauling a 5,000-pound payload. And although the trucks are Class 3, meaning they’re not required to comply with the same safety standards as passenger vehicles, they include standard anti-lock brakes and stability control.

More about the battery pack

The Chass-E includes a 105-kwh or 140-kwh battery pack and 15-kw “export power.” Bollinger has suggested—today and in the past—that the priority is sustained power output rather than range, although the range is expected to roll in at 200 miles or more for many versions.

Bollinger energy density vs. power density

He referred to its proprietary battery pack, first detailed last fall, as the “diesel version” of an EV pack, with high sustained power output. The somewhat T-shaped pack (flat in the 105-kwh or 140-kwh configurations) is 350-volt or 700-volt compatible, and fast-charges to CCS standards.

Bollinger battery packs

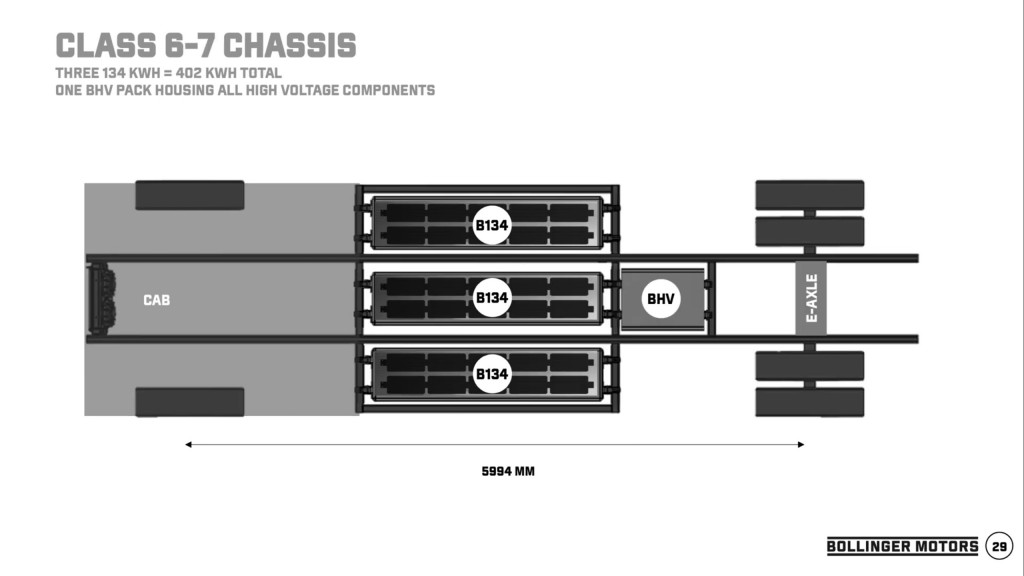

It’s built with 35-kwh “strings” of 16 modules each—obtained from a “Tier 1 supplier”—assembled in series or parallel to obtain a 350V or 700V layout. Using a combination of these packs inside and outside frame rails, Class 6 or 7 trucks could carry 402 kwh of energy capacity, according to Bollinger.

Bollinger Class 6-7 battery layout

The company is also working on building a series of frame-suspended high-voltage components for the battery, the hydraulic steering, and for air brakes.

Bollinger still plans to use contract manufacturers to build the trucks, although it hasn’t yet announced those partners. Deliveries of the B1, B2, and all the Chass-E versions are due to start in 2022.