Former Tesla 4680 battery cell production engineer James Herbermann has been named Vice President of Manufacturing at the American Battery Factory (ABF).

“James brings to American Battery Factory incredible perspective and front row experiences in evolving battery cell technology and is the perfect complement to our team as we begin our journey to develop a domestic battery manufacturing ecosystem that will make energy independence and renewable energy a reality for the United States,” ABF CEO and President Paul Charles said. “As we lay the foundation for our factory network, I am confident James’ cross-functional leadership will not only enhance the efficiency of ABF’s modular approach to manufacturing, but it will also propel our unwavering quest to develop the longest-lasting LFP prismatic battery cells on the market.”

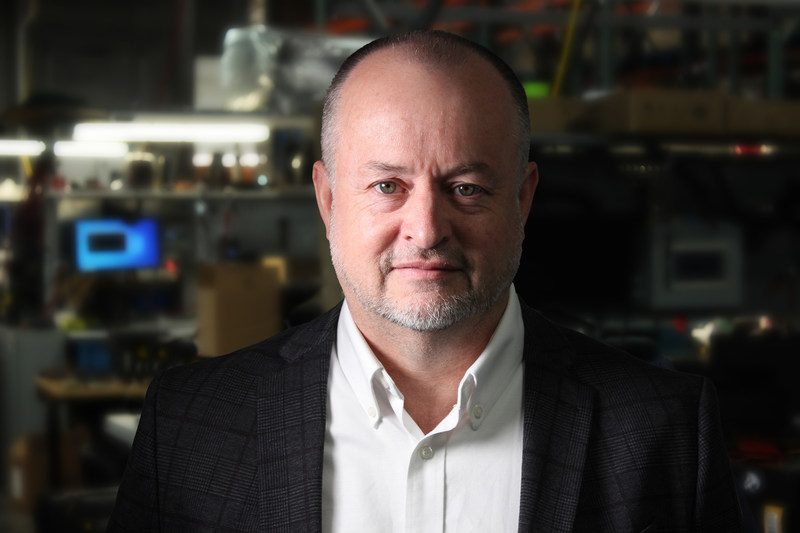

James Herbermann, formerly with Tesla, joins American Battery Factory as its new Vice President of Manufacturing.

ABF is working to develop the United States’ first network of Lithium-Iron Phosphate, or LFP, battery cell gigafactories. The LFP cell is a major part of many automakers’ plans for future electric vehicles as more cell chemistries are being utilized to combat excessive demand. Tesla, for example, started transitioning its Standard Range trim levels to LFP batteries last year. The automaker confirmed that it would utilize the cell chemistry in lower range vehicle as they are less expensive and have longer lifespans. They do have their disadvantages, especially in terms of energy density, which means less power and range with EVs that utilize these packs. They are also more likely to be affected by adverse weather conditions, especially in colder climates.

CEO Elon Musk has said in the past that LFP packs want to be charged to 100 percent, as opposed to nickel-based packs that prefer a 90 percent state of charge.

Tesla is just one of the companies working to use LFP cells. Rivian, Ford, and Volkswagen are also utilizing the cell chemistry for some of their vehicles. Therefore, the need to produce more cells to provide automakers and customers with suitable options is definitely a work in progress.

Tesla says ‘nearly half’ of the vehicles it produced in Q1 equipped LFP batteries

ABF is working to eliminate LFP shortages with a series of production plants across the U.S., and the company is looking for Herbermann to lead and support all aspects of its manufacturing and production operations. Prior to ABF, Herbermann worked at Tesla to lead the development and scaling of its new battery electrode processes in Austin from the pilot program to a full-scale production process. He was a direct piece of Tesla’s commercialization of the 4680 cells, which has been installed in early builds of the Model Y from the new Austin factory. Additionally, Herbermann has developed “novel Sodium Titanium Phosphate; F1 racing Li-Ion cells; Aquion Hybrid Ion (AHI®); Duracell Ultra®; Comfort Plus® modular carpet tiles; and ZIP Wall® sheathing,” a press release from ABF said.

“I am inspired by ABF’s mission to develop a domestic supply chain for LFP batteries, especially in light of the pandemic’s crippling effect on availability and our country’s glaring void in battery cell manufacturing,” Herbermann said about his new role. “With its strategic approach of constructing a network of modular rapid construction factories near or onsite at pack integrators and energy solution providers, ABF is on track to solve one of the planet’s most pressing energy needs. I look forward to being a part of this impactful work.”

I’d love to hear from you! f you have any comments, concerns, or questions, please email me at joey@teslarati.com. You can also reach me on Twitter @KlenderJoey, or if you have news tips, you can email us at tips@teslarati.com.