The global chip shortage’s effect on current products is clear in just about every consumer market in the developed world, reflected in half-empty car dealerships and shuttered manufacturing lines. COVID gets a lot of the blame—and it sure didn’t help—but the fact is, the proliferation of gadgets in everyday life had been a slow-moving train that was long on track to disrupting the semiconductor supply/demand balance.

The end, unfortunately, is not near. Yuh-Jier Mii, R&D chief at the world’s largest contract chip manufacturer, Taiwan Semiconductor Manufacturing Corp., recently told Spectrum he personally believes it will take two to three years to get enough new fabrication facilities on line to adequately address the shortfall.

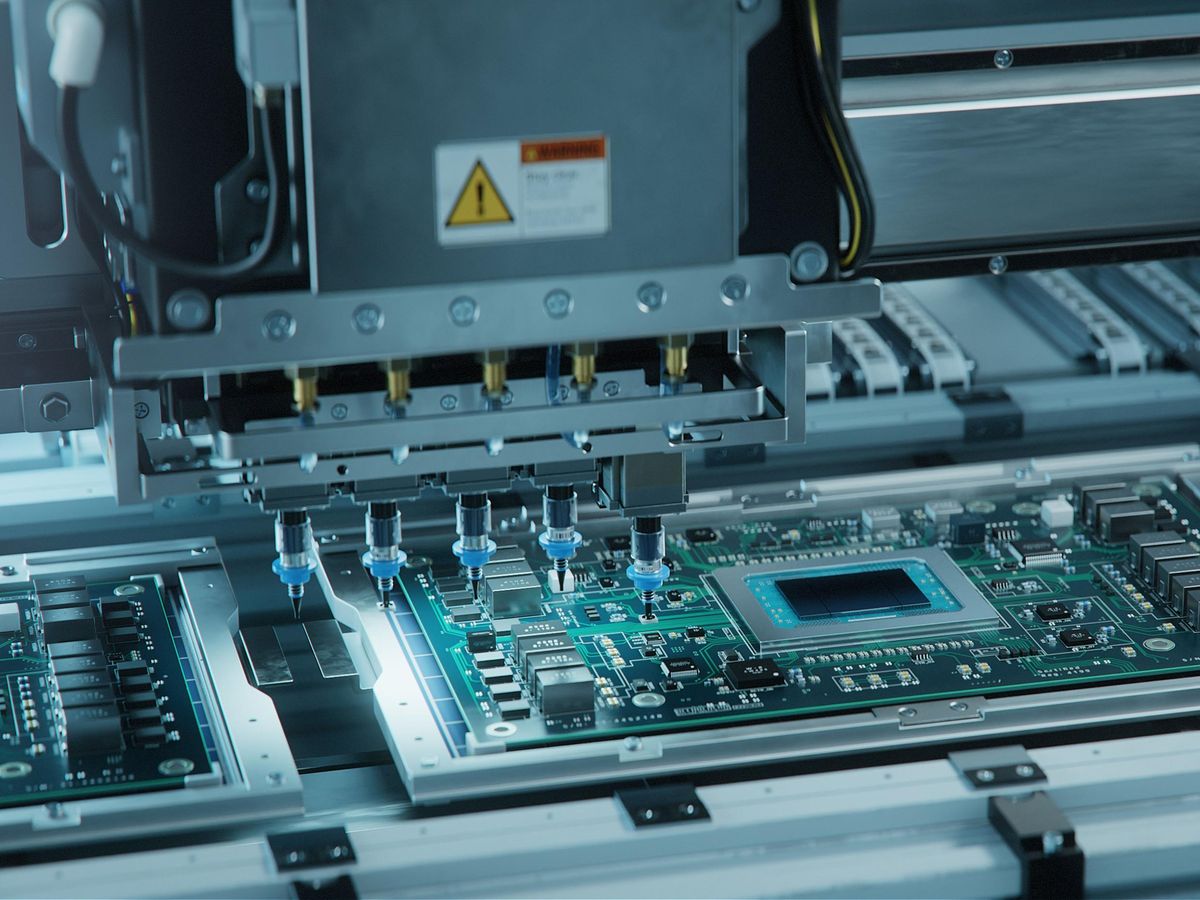

So the shortage isn’t just affecting the availability of current gadgets. The lack of chips is already fueling changes in the design of future products, delaying the next generations of devices, and forcing engineers to come up with all manner of Plan Bs, according to a new survey from Avnet.

The study found 64 percent of the global engineers polled say their companies are increasingly designing products based on the availability of components, rather than just following their preferences, regardless of availability. This finding and more (see below) highlights how the chip shortage will alter technology—and tech jobs—for years to come.

“Just as [technologists] have had to think about manufacturability and testability, we need to start thinking about ‘procurability,’” says Samuel Russ, an associate professor of electrical engineering at the University of South Alabama. “It’s got to become part of the engineer’s lexicon, and we’ve got to figure out better ways to be more agile.”

Russ stresses that tech workers shouldn’t view the crunch as a temporary problem to work around when designing. It’s a real-world component of the landscape that’s fundamentally altering how technologists, designers, and engineers work—and could just as readily affect what tech is made, by whom, and when.

“In the past, design was separate from procurement. It was based on the technology—you pass it to the sourcing organization, you move that into production,” says Peggy Carrieres, Avnet’s vice president of global sales enablement and supplier development. Product designers, engineers, and tech specialists who participated in the survey, she says, these days “have to think about [component] availability from day one.”

That availability is particularly low for microcontrollers (a.k.a. microcontroller units, or MCUs), Avnet found. Russ noted that unlike in the CPU world, which has Intel and AMD and then “scenery-chewing extras,” the MCU space is a dozen different companies of roughly equal size. “The problem with MCUs is that it’s not one or two parts; it’s like 100 different parts that are low-volume products,” Russ says. “So it’s a lot harder to keep those in stock, especially if fab lines are starting to have to decide how to allocate. They’re obviously going want to focus on the high-volume stuff.”

The supply/demand imbalance has helped to push MCU costs significantly higher, but that’s not the only reason for the price spike. It’s also the macro factors affecting the economy at large, Carrieres notes: inflation, higher labor costs, intermittent shutdowns, and soaring prices for materials like palladium, which topped US $3,000 an ounce in March.

“It takes a while to rebalance that whole supply chain, and we’ve got these mega trends happening,” Carrieres says. “There’s ever more demand, and the cost to manufacture has gone up, so that has to be reflected in the end selling price.”

Engineers are being forced into “behavioral” changes when it comes to design and product generation road maps, Carrieres says: “They’re delaying the next-gen project and extending something that’s already in production because they may have already had the mix of materials for that previous production. It’s pushing out the innovation cycle—or removing features in the current production cycle—because they’ve got to focus on, ‘Well, what do we have available to build?’”

This chart highlights the challenges for design engineers and the limited options for alternative paths. “None of the options are great—if you can find a pin-to-pin replacement, that’s the easiest, you know, sure. That may or may not be possible,” Russ says. “But other than that, what can you do, right? You’ve either got to redesign the board or come up with some kind of adapter. You have to start making those considerations: How easily can the board be redesigned? How high is the volume of production for your board?”

The successful design engineer will have to take a holistic view of everything it takes to get the product to market, Russ and Carrieres agreed. Says Russ: “In a situation like this where the industry is throwing you curveballs, you have to have a 360-degree view of your product. Is it manufacturable, is it procurable? What does it do to the cost, what does it do to the performance? [Tech designers and engineers] especially have got to keep the procurement organization and the manufacturing organization on speed dial.”

While engineers have always needed a strategic view to some extent, Carrieres says, “The forces that are at play today are so much more complex. So when you start your design, even from the first sketch, look beyond the board. It’s tempting to go deep into that design and stay focused on the technology, but they have to look beyond the board to be successful.”

- TSMC R&D Chief: There's Light at the End of the Chip Shortage ... ›

- These 5 Charts Help Demystify the Global Chip Shortage - IEEE ... ›

Julianne Pepitone is a freelance journalist who reports via text, video, and television. She spent years on staff at CNN Business and then at NBC News, covering consumer tech, cybersecurity, and business. Now a freelancer, she works with an eclectic roster of clients. Beyond Spectrum, CNN, and NBC, her bylines can also be found at HGTV Magazine, Memorial Sloan Kettering, NYMag.com, Glassdoor, Popular Mechanics, Cosmopolitan, Town & Country, Thrillist, MagnifyMoney, The Village Voice, and more.