Any potential industry shift toward cylindrical battery cells in EVs is far from a foregone conclusion, let alone an actual trend. Case in point: The battery supplier CATL makes a strong argument for the prismatic format with the latest version of its cell-to-pack battery technology, which skips the idea of battery modules entirely.

CATL last week disclosed more details regarding its third-generation tech, which is also referred to as Qilin, or CTP 3.0. CATL revealed Qilin earlier this spring with the claim that it could produce more power than the latest battery tech from Tesla.

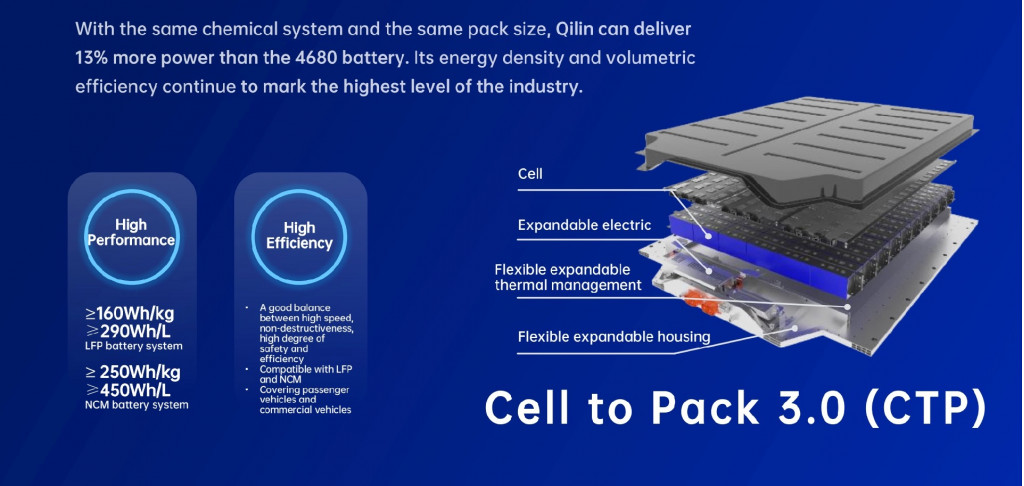

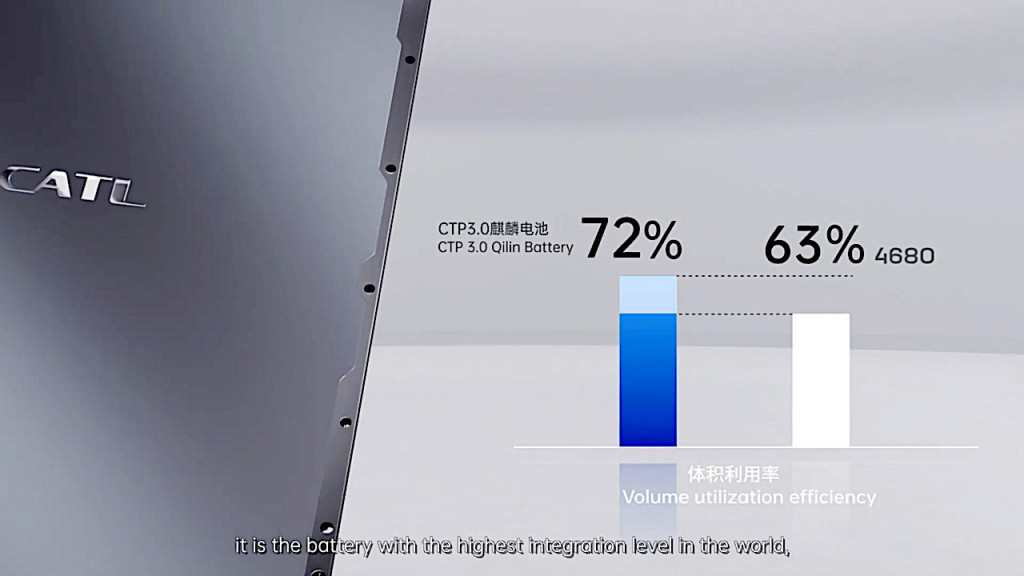

It says that the cell-to-pack system can deliver 13% more power by volume than Tesla’s 4680 battery, with an energy density of 255 Wh/kg with current-tech lithium-ion cells and 160 Wh/kg for LFP cells—delivering more than a 1,000-km range (621 miles) “in a breeze,” claimed the company.

CATL third-generation cell-to-pack tech

CTP 3.0 is designed around a flexible expandable thermal management and housing—altogether part of a “sandwich structure,” the company calls it, replacing a three-piece construction of the previous versions.

Flexible micron bridges between the cells can also help adapt to physical changes inside the packs, aiding reliability. Perhaps most noteworthy, CATL boasts of a “disruptive” water-cooling design for the pack.

It offers a 50% boost in thermal efficiency versus the previous pack design and has four times the heat transfer area versus before. Cooling channels between adjacent cells allow faster responses in temperature conditioning for a hot start in cold weather (5 minutes), or 10-minute DC fast-charging (10-80%).

CATL claims the more aggressive cooling strategy makes it compatible with “materials with higher energy density”—a strong hint it’s looking ahead to other future chemistries such as sodium-ion cells.

CATL CTP 3.0 cell-to-pack battery tech

CATL CTP 3.0 cell-to-pack battery tech

In all, the CATL system offers an impressive 72% volume utilization efficiency—meaning that portion of the volume is dedicated to battery cells, with the remainder for the structure, connections, safety features, and cooling. That’s a big improvement versus the 55% volume utilization efficiency of the original CATL cell-to-pack system revealed in 2019.

The cell-to-pack tech is also a building block for CATL’s Evogo battery-swapping business, which could help fit a lot more price flexibility into EVs. So far, Evogo is focused on China.

Although CATL’s CTP is thus far focused around the prismatic format, the logic and improvements could feasibly be extended to cylindrical cells. Recently, BMW reportedly pivoted to the Chinese supplier as one of its primary sources for cylindrical cells in next-generation EVs.

CTP 3.0 will be mass-produced in China and will be due in production models soon, CATL says. Hyundai, Kia, and Genesis are among the brands that have already agreed to use the tech, although specific models haven’t yet been confirmed.