The emerging electric vehicle market is getting a lot of attention, but the electrification of electric trucks is lagging far behind. On current trends, passenger electric cars, electric buses and other light commercial vehicles may reach the numbers needed for zero emissions by 2050, but medium and heavy trucks are off track. According to BNEF, electric trucks would need to account for about 95 percent of sales in 2040 to meet emissions targets by 2050, but current projections are that they will account for only about 35 percent.

Current market trends are bound to drive significant growth in sales of electric trucks, both in terms of environmental protection and economic benefits. However, they are still scarce and expensive compared to electric passenger vehicles, so let’s analyze the keys to enabling electric trucks’ large-scale development.

The benefits of electric trucks

Compared to fuel trucks, electric trucks can reduce operating costs by 14% to 52%, and maintenance costs can be reduced by about 40%. These savings, combined with the continuing decline in battery prices, make electric trucks increasingly affordable. While the upfront costs of most electric trucks are still high today, studies show that the life-cycle costs of electric trucks are lower than those of fuel trucks. And states like California and New York offer incentives for purchasing electric trucks.

Although medium- and heavy-duty trucks account for only about 5 percent of vehicles on the road, they are responsible for 29 percent of the transportation sector’s greenhouse gas emissions, or about 7 percent of the U.S. total. Fleet operators can, therefore, not only save on high operating costs but also contribute to environmental protection. These significant benefits of electric trucks are sure to be one of the keys to their massive growth.

The cost of electric trucks

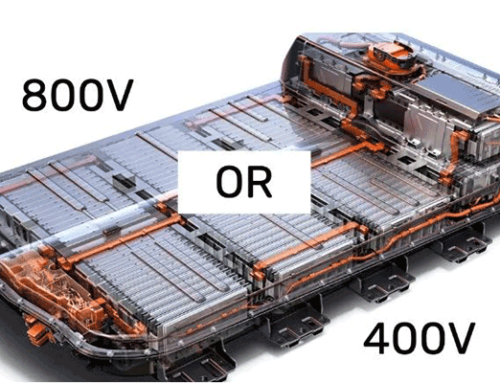

The high initial purchase cost of electric trucks is the biggest obstacle for fleet operators. Large trucks have different requirements for power and charging and require larger batteries than passenger cars, so batteries for electric trucks are currently 2 to 3 times more expensive than passenger car batteries. Fortunately, BloombergNEF’s annual Battery Price Survey found that lithium-ion battery pack prices fell 13 percent in the last year alone. BNEF anticipates this price will continue to drop the pace to help EVs achieve price parity with internal combustion engine vehicles within the next three years globally.

Charging infrastructure

Today there is only a handful of charging stations in the U.S. equipped to serve the needs of heavy-duty electric trucks. The charging infrastructure needs to meet the fleet’s needs, not only in terms of quantity but also in terms of charging power. An example is a 300 kW high-power charger like SETEC POWER. Because of the attributes of a truck driver’s job, only a high-power charger can provide them with the shorter charging time they need.

And while most early electric truck deployments currently rely on private charging infrastructure, plans are being developed to build-out accessible public charging. For example, the West Coast Clean Transit Corridor Initiative — a collaboration among electric utilities and agencies representing municipal utilities — proposed a plan to build out charging infrastructure along 1,300 miles of Interstate 5 to support medium- and heavy-duty electric trucks from the Mexican to the Canadian border.

The pace of battery technology advancement is happening faster than we thought, and battery costs are also dropping faster than anticipated. Manufacturers like Daimler, Volvo and Tesla are rolling out new zero-emission heavy-duty trucks with policy support, and I’m sure we’ll soon see electric trucks on every corner. Of course, if you lay out the business of electric truck charging infrastructure in advance, you will indeed have a bright future too.