All electric vehicle users and charging equipment manufacturers expect EV charging to be as fast as refueling. Faster charging relies on a higher power, and current Extreme Fast Chargers (XFCs) can exceed 350kW or more. Such power generates a lot of heat, so how do we deal with this heat?

Air-cooled and liquid-cooled

Traditionally, air cooling has been the preferred solution. Liquid cooling has proven to be the most effective, as air cooling dissipates heat more slowly. The heat capacity of water is also 3,500 times more efficient than the same volume of air, and up to 10 times more effective at dissipating heat from the source. Liquid cooling systems can also significantly reduce the size and weight of cables by about 40%, making them more suitable for the thermal management needs of high-power chargers and a natural choice.

Air cooling system

- Low cost, easy installation, high post maintenance cost

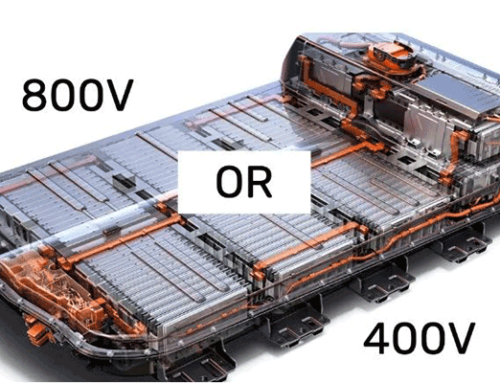

- Limited cooling capacity, heat transfer coefficient between 30~50W/㎡K, suitable for charging modules under 30KW

- Air-cooled systems are susceptible to air quality, leading to corrosion or dust buildup

- Fan rotation noise and energy consumption is large

Liquid cooling system

- Higher installation cost, low failure rate, low post-maintenance cost

- Strong liquid cooling capacity, heat transfer coefficient between 3000~10000W/㎡K, more than a hundred times that of air, suitable for high-power application scenarios

- No contact with the external environment reduces the influence of dust, moisture, etc., and high stability

- Significant reduction in noise and energy consumption, avoiding complaint problems

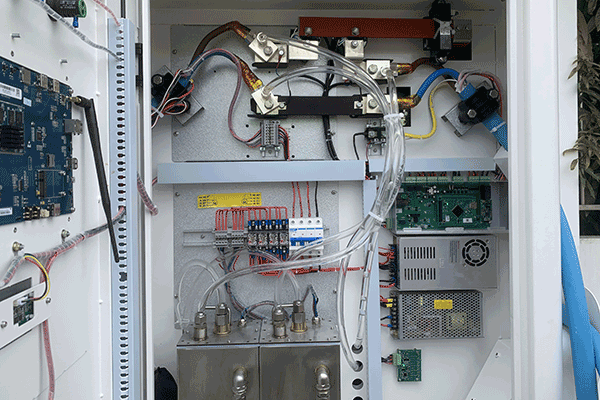

SETEC POWER Liquid Cooling Solution

SETEC POWER’s DC fast chargers all support the customization of liquid cooling systems and have proven their quality and performance in a variety of large projects. The core of the liquid-cooled charging system is the liquid-cooled charging module. Cooling pipes are added to the electric vehicle charger circuit, cables and connectors. The liquid-cooled system circulates the coolant through these cooling pipes by pumping it through the system, while the heat is removed by fans or coolers.

Many of our customers are worried about the cost of adding liquid cooling to their 180KW or 300KW charging station. Liquid cooling systems are currently more expensive to set up than air-cooled systems, but they are still very cost-effective in terms of the overall life cycle of the equipment. Typically, air-cooled systems are under a lifespan of 3-5 years, while liquid-cooled systems can have a lifespan of over 10 years. On average, air-cooled systems require maintenance about 6 times per year, while liquid-cooled systems only require routine checks.

Therefore, it is easy to see that liquid cooling is undoubtedly the most effective solution to the problem of heat dissipation in large metric electric vehicle charging stations. And it has been widely used and proven in SETEC POWER’s equipment.