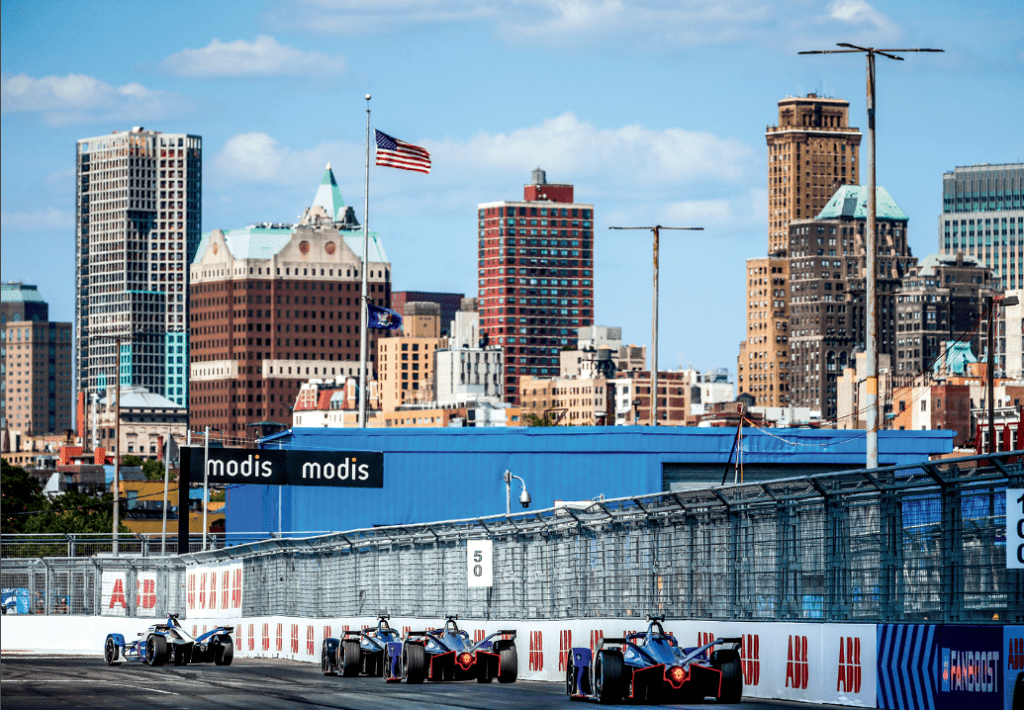

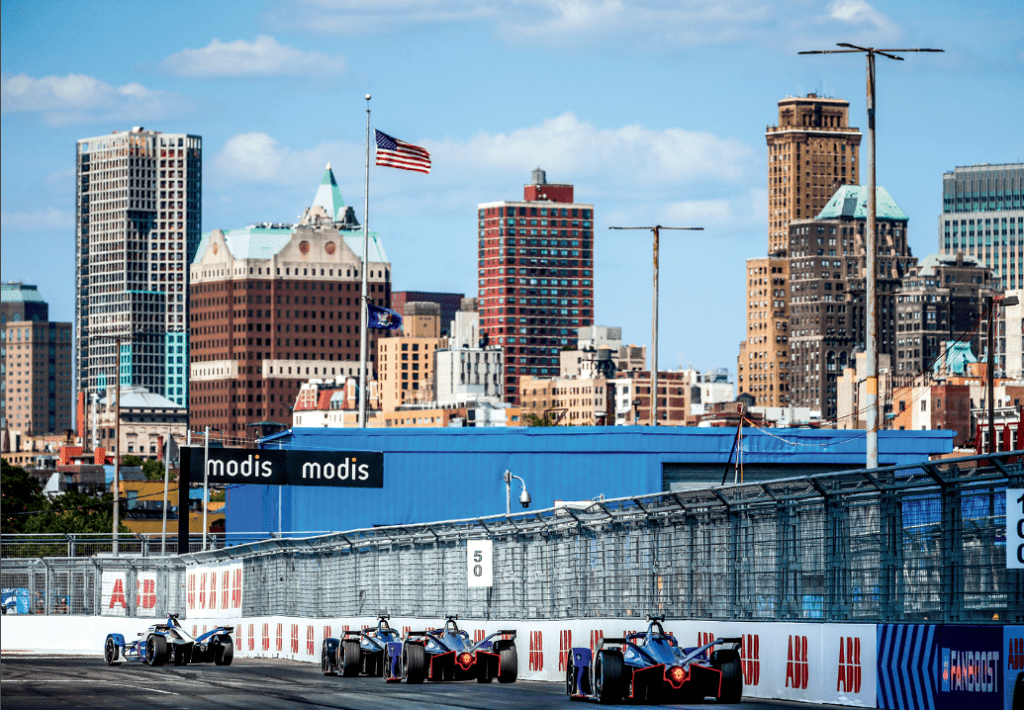

The global electric racing championship Formula E has been a huge success by any measure. Automakers like Mercedes-Benz, Porsche, Nissan, and Jaguar have embraced the series, which is surely the world’s most prominent showcase for electric vehicle performance. Charged attended the New York City E-Prix in July, and spoke with several execs from EV infrastructure powerhouse ABB. All told us that their partnership with the electric racing series has brought a tremendous amount of public awareness to the company, and of course, to e-mobility in general.

However, for ABB and the many other companies involved with Formula E, it’s by no means all about marketing—there’s some important product development going on. As the saying goes, “Race on Sunday, sell on Monday.” ABB’s work with Formula E (and with the participating OEMs, all of which are also ABB partners) has led to numerous practical advances.

From the racetrack to the street

“A lot of what we do with Formula E, we’ll pull the lessons learned and the improvements to our mass-market chargers or equipment,” ABB Global E-Mobility Executive Stephanie Medeiros told Charged. ABB is currently providing UPS systems for Formula E’s broadcast center, and it provided 50-kilowatt chargers for the Jaguar I-Pace trophy, a racing series that was presented before the main Formula E races for two seasons from 2018 to 2020.

A lot of what we do with Formula E, we’ll pull the lessons learned and the improvements to our mass-market chargers or equipment.

The real action will begin with the 2022/23 season, when ABB will become the official infrastructure supplier for Formula E. The companies are already working closely together to develop a third-generation charging system that will allow the Formula E racers to charge in less than a minute during pit stops, adding a new dimension to the races.

“We’ve been [working] on it for quite a while now—we’re designing the specifications, working on the prototypes,” Ms. Medeiros told us. (Technical specs such as voltage and power levels haven’t been announced yet.)

The Gen3 charging system will supercharge not only the race cars, but also the promotional value of the racing series. “The power will be higher, so we can promote even more how EVs are exciting to drive, and the fast charging tech will give the opportunity to show that the range and the time of charging is becoming less of an issue nowadays,” said Medeiros.

We asked for an example of how something that was developed for Formula E would have wider applications for ABB’s everyday customers.

“Formula E is a very unique application, because not only are we taking this equipment and shipping it all around the world, but we’re also connecting it to so many different power sources and different grids,” said Medeiros. “Typically, with electrical equipment, you install it and then you just leave it there for 10, 15-plus years. We’re taking this [equipment for Formula E] and shipping it around the world. You have to make sure that the equipment is robust and reliable enough that it will work when you get to the next destination. That’s a lot of really good data…there’s so much value and data we can take from that.”

“And the same thing with the chargers,” Medeiros continued. “The mobile [Gen3] chargers are going to be wheeled, because you want to maneuver them very easily when we put them in garages. It’s power electronics—you want to make sure that it’s safe, reliable and robust, so that when you plug it in, no matter what kind of rate or energy source, you’re going to get something that’s reliable. We’re going to take those lessons learned, and then put it into chargers.”

Efficiency is everything

In the racing world, efficiency and weight are critical, and advances made in the pursuit of speed can also yield advantages in terms of range and vehicle design that can be applied to less glamorous vehicles. “Energy management is EVs,” Formula E Chief Championship Officer Alberto Longo told us. “You need to manage your energy in order to be efficient. Efficiency is what we are about. This is not about who is going the fastest. This is about who is managing energy better.”

Efficiency is what we are about. This is not about who is going the fastest. This is about who is managing energy better.

Dan O’Shea, Director of Utility Strategy and Business Development for ABB in the US, gave us some more examples of the two-way exchange of ideas between Formula E and more mundane markets.

When Formula E started, range was limited, so each driver had two cars, and performed a swap mid-race. The Gen2 racer has enough range to last the whole 45-minute race, and the Gen3 car’s super-fast charging will make it possible to reduce the battery size. “As you progress, the batteries get smaller, because you can charge it faster,” said O’Shea. “Well, this is happening in the commercial space with trucks and buses. When electric transit buses first hit the market, they had an inverter on board, and they charged with alternating current. Now, the general consensus seems to be that having the [AC-to-DC] conversion happen off-board lightens the bus, and makes room for a bigger battery. As the batteries get denser, that bus will have more range, and maybe more flexibility, because the charging will happen with DC. Bringing the charging off-board, to [lighten] the vehicles, you can see that this is happening in Formula E. There’s obviously this technological synergy between what happens in Formula E and what makes it to the commercial model.”

Don’t most of today’s e-buses offer both Level 2 and DC charging? “Some of them do, but I don’t know that they’re being made that way anymore,” says O’Shea. “With CCS combo, you’ve got your J1772 Level 2 and your CCS in one port. If you have that port, you do have the option [of using AC or DC charging], if you have an inverter on the bus. The industry is still so young—I can’t tell you that in five years it’s going to be that way. I was told adamantly, five years ago, that AC charging was what was going to be happening with buses. And that is not the case.”

“We work closely with the auto, bus and truck OEMs to create the products that they’re going to need, and we’re in development constantly. We have a unit today called the Terra 184, which is 180 kilowatts in a smaller form factor. This cabinet is the same size as our 50-kilowatt cabinet, which can charge one vehicle at a time. Now you’ve got a cabinet with the same footprint, with 180 kilowatts, but it can charge two cars at 90 kW. The progress of the power electronics makes for smaller and more efficient power modules. We’ll be applying that kind of technological progress to the Formula E Gen3 charging application.”

Like computers, EVSE components continually get faster, smaller and cheaper. “Sometimes I use the comparison to Moore’s law,” said O’Shea. “It’s not really that crazy of a compression time—12 to 18 months, halving in size and doubling in power—but it is analogous. Like I said: 50 kilowatts, seven years later, same size cabinet, 180 kilowatts. What’s happening there? The power modules are denser, components are smaller. The unit is a lot smarter.”

Fleets are neat

What’s the hottest and fastest-growing area in the EV world at the moment? “I would say fleets,” says Stephanie Medeiros. “Obviously, for the last few years, it’s been passenger cars, and we’re not done with electrifying passenger cars. The next big thing was electric buses. Now it’s fleets, and that’s coming in huge, huge numbers. When looking at the total emissions that come from transportation, commercial transport [is a major part of it] especially as you’ve seen during the pandemic where deliveries just increased significantly. Obviously if you electrify that, you’re really going a long way to cleaning up the air.”

The fleet market may be red-hot today, but as battery prices continue to decrease, demand for fleet EVs, and associated charging services, could break the thermometer. “We always talk about the total cost of ownership of an electric vehicle, and that’s pretty much on par with a combustion engine vehicle, because maintenance costs are lower, and [charging cost] is usually lower,” said Medeiros. “But what’s really important is upfront cost, and we know that upfront cost is going to go down year over year. A lot of studies are saying that, in five years, electric passenger cars will be cheaper on average than combustion engine cars. And that’s mostly due to the battery. Once you get to that point—because obviously when you’re electrifying commercial fleets, the ROI is super-important—then it’s going to be making the overall story for electrification more attractive.”

One of the hottest topics on the EV scene these days is charging management for vehicle fleets. Charging large numbers of vehicles at once requires a complex package of hardware, software and services to maximize reliability and efficiency, and minimize costs. Naturally ABB is involved in this area, but the company is working with a partner to provide charging management services to its EVSE customers.

“We have an excellent partner called In-Charge Energy [the subject of a feature in our March/April 2020 issue], and they do a great job of offering turnkey solutions for fleets,” Dan O’Shea told us. “They have a team of some of the most qualified, experienced charging people in the world. They work with our hardware primarily, and they have software as well that addresses the needs of the vehicles, and also of the building—energy management behind the meter, on the customer side. They offer that service. There are other companies that do just the software—you’ve got Mobility House, ViriCiti, Electriphi, which was just purchased by Ford.”

“The fleet sector has pulled ahead. At first [our focus] was public charging—we had to get chargers on the road so that people [wouldn’t] have range anxiety. This was really the focus in 2010 through 2013. Once fleet managers understood that the return on investment, and total cost of ownership of these vehicles, was better than gas, and they could justify that largely without incentives, that really accelerated the development of fleets, and that incited development in the energy management space. There’ll be more of that. We are developing, and have developed, fleet-specific solutions. We have a lot of bus operators that use our software to operate the chargers on the buses. And then when it gets more complex, when energy management is needed, they layer the fleet-specific software on top.”

Coming attractions

CHARin, a consortium of vehicle OEMs and other players, is developing a new charging standard for heavy-duty vehicles, called the Megawatt Charging System (MCS). We asked O’Shea if MCS is the coming thing, and if there are any competing standards in development. “There’s testing going on at the labs with the auto OEMs and the charging manufacturers, and they’ve come up with a megawatt connection,” he told us. “We participate in CHARin, we’re a founding member. There are technical hurdles, cooling being the primary one, whether or not a human is going to actually operate that, or it’s going to be automated, for the actual connection, there are things to work out, but it is happening. It’s amazing. I don’t know of other standards that are working on a megawatt—it doesn’t mean there aren’t any.”

I also asked O’Shea about vehicle autonomy as a solution for the problem of drivers who don’t have the option of installing a home charger. Could self-driving cars go off and charge themselves in the middle of the night?

“Is that here, or on Mars?” O’Shea quipped. “I talk about this a lot because I get asked about driverless, autonomous and self-parking. It’s a thing that is eventually going to hit the streets, but the merging of humans and computers driving together is something that needs to be worked out. Now, with a fleet situation, let’s imagine that your driver gets back [to the depot], and just has to leave the vehicle at the gate. We already know that a vehicle can find its way to a parking spot. That already happens, so I could see that that would be a viable technology to deploy.”

“For ABB e-mobility, when they need hardware to charge it, we’re going to make it. Whatever format that needs to be [for an] automated charging experience, we’ll be able to do it. We’re network- and software-agnostic. If it’s on the Open Charge Point Protocol [OCCP] platform, we’ll be able to provide the hardware and the network services that need to be applied for that solution.”

Is ABB pushing for one solution or the other? “Not really. We lead in the development of power electronics for the use cases that are out there. Would we build something because we think there’ll be a market for it? We know where the market is now, and we’re building and releasing products for it.”

It’s always been bigger, faster, better, right? You go to 350, you go to 600, a megawatt. Well, we released a 24-kilowatt charger, and this is probably the most popular launch of a product we’ve ever done.

“I’ll give you an example. We released a 24-kilowatt DC charger last year. There’s a three-phase version and a single-phase version. I wasn’t exactly sure what the uptake of that would be, because since the first 50-kilowatt charger came out, it’s always been bigger, faster, better, right? You go to 350, you go to 600, a megawatt. Well, we released a 24-kilowatt charger, and this is probably the most popular launch of a product we’ve ever done.”

“What it really speaks to is that it’s about the use case. How long is that vehicle going to be parked there? When is it needed? And if you can mitigate your upstream electrical service, and limit those costs by having a 24-kilowatt charger, instead of a 50 or 150, why would you not do that? I used to say, your car is like your cat—it’s asleep most of the time. It charges when it’s asleep. Now, if you have a depot where you need your cars every eight hours, or you know the dwell time, then you can do the backwards math up the electrical supply chain, to see what power you need so that that vehicle is ready at 6 am. It doesn’t have to be 50, 150 or 350—it could be 24.”

What kind of customers are buying the new 24 kW model? “A lot of auto OEMs for their dealerships, and fleets. We have a great deal with Lion Electric. Their trucks are selling with our 24-kilowatt unit. We have bus companies that want the 24-kilowatt. We have others that want 150. It’s about the dwell time, and the use case.”

ABB: Early EV leader

It’s quite fitting that the lead corporate sponsor of Formula E is ABB, a global electronics giant that is involved in many aspects of the electromobility industry, from charging infrastructure to batteries to utility integration to robotics.

The company’s name reflects its Swedish and Swiss roots: the A is for ASEA, an electrical manufacturer founded in Sweden in 1883, and the BB is for Brown, Boveri, a group of electrical engineering companies formed in 1891 in Switzerland.

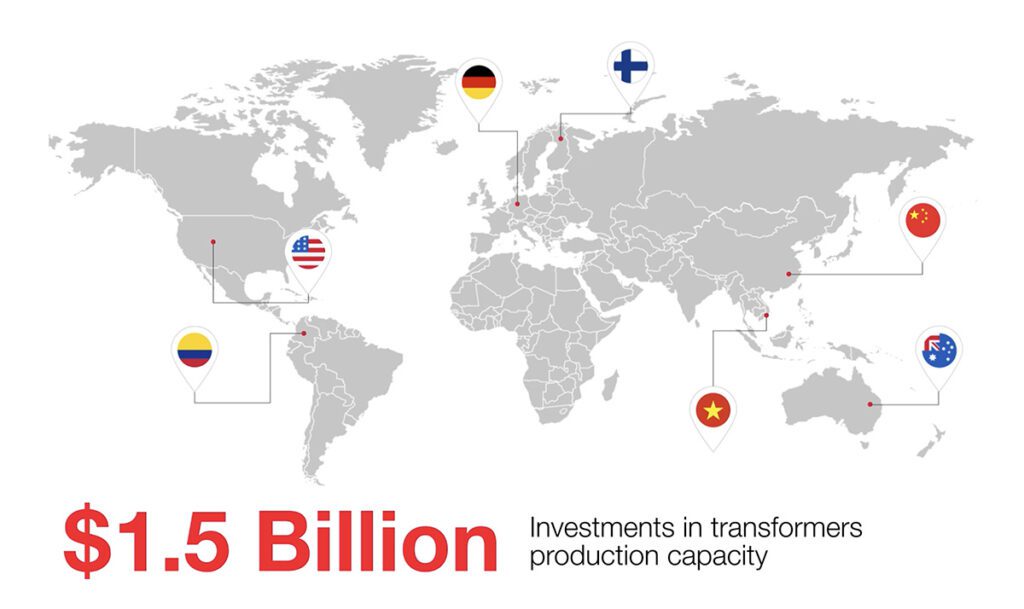

ABB is a major manufacturer of EV charging hardware—it provides chargers for some of the world’s largest public charging networks, including Electrify America and Europe’s IONITY, and for many large EV fleets around the world. Just to give two examples, in June the company announced a deal to supply 2,000 AC charging stations to Austria’s postal service, and another to provide charging infrastructure for 1,000 electric buses in Qatar.

Also in the past few months, ABB has sold electric power systems for ferries in Lisbon, bi-directional chargers for V2G kiosks in France, an energy storage system for highway chargers in Switzerland, fast chargers for utilities in Japan…the list goes on and on. “When they need hardware to charge it, we’re going to make it,” Director of Utility Strategy and Business Development Dan O’Shea told Charged.

Full disclosure: ABB has been a regular advertiser in Charged since our early days.

Formula E’s founders

There are more manufacturers involved in Formula E than in any other form of motorsport in the world, and one reason for this is because it’s an exciting way for companies to promote their electrification efforts. In fact, part of the impetus for creating Formula E was to appeal to sponsors who wanted to green up their images.

At the New York City E-Prix in July, Formula E co-founder and Chief Championship Officer Alberto Longo told Charged that, back in 2012, a lot of sponsors were starting to be concerned about the environmental aspects of gas-powered motorsports. “It wasn’t the right messaging for their companies. I knew that we needed to create a platform that really invited all these big brands that didn’t have a place in promoting [gas-powered racing] because of the sustainability angle.”

As the legend goes, Alejandro Agag met with some big-time motorsport sponsors at a restaurant in Paris, and told them that if they ever organized an electric championship, he would love to be the promoter. They were non-committal, but he insisted that they sign something on the spot, so they signed a preliminary agreement on a napkin, which laid the groundwork for the founding of Formula E.

Agag became the CEO, and the rest, as they say, is history. Formula E (officially the ABB FIA Formula E World Championship) has been a huge success, not only as a showcase for EVs, but as an exciting sporting event that attracts loads of spectators both live and broadcast. It’s also a financial success—the series came very close to turning its first profit during the 2019-2020 season, despite having to cancel 9 of the 14 scheduled races due to the pandemic. The series was just wrapping up its seventh season as we went to press, and planning its eighth for 2021/2022, which will include 16 races in 12 locations, from Cape Town to Vancouver to Seoul.

Alberto Longo told us about some of the big changes in store for the following 2022/23 season, which will feature a redesigned Gen3 race car. “Every four years, I think we need to change, because technology is advancing so quickly that every four years, your technology is obsolete—completely, 100%. ABB is such a great partner for that. But, at the same time, we’re taking care of the [investment] of the teams. We don’t change earlier than that.”

“It’s going to be a much nimbler car, much quicker. The weight of the battery is going to be much lower, and it’s going to have more range. And obviously that means that the cars are going to be way quicker than they are today. The batteries are going to be exactly the same for all cars—the powertrain is going to be what the teams and manufacturers can play with.”

Some have accused Formula E of hypocrisy, because although the race cars are electric, staging the event requires a large number of diesel trucks (at the 2019 race in Bern, protesters rode bicycles around the racecourse to highlight the irony). Formula E is continually working to reduce its environmental footprint.

“Sustainability measures are totally linked to efficiency as well,” Longo told us. “We travel the world with more than 300 tons of equipment. That’s not efficient. We need to talk to our teams, in order to reduce as much as possible the footprint that we leave. Efficiency has always been at the core of Formula E, but we’re pushing the boundaries there, and hopefully we will get way more efficient. I’m calculating more than 35% saving of CO2 emissions, by the new way that we’re going to manage our logistics.”

“Combustion engines are over, end of story,” Longo concludes. “You can believe it, you can not believe it, but this is happening now. It’s not the future anymore. Most of the first-world countries in the world today, they’re banning the sale of internal combustion engine cars [by] 2025, 2030. The commercial interests of all the big manufacturers are aligned with a platform like Formula E. The investment that these manufacturers are putting into EV technology is going to make us grow way faster than any other form of motorsport.”

This article appeared in Charged Issue 56 – July/Aug 2021 – Subscribe now.