Because of the various limitations of charging infrastructure, permanent EV charging stations are not the only option for many companies. SETEC POWER has developed the Emergency mobile EV charging system, a solution that can be customized to meet your specific charging needs to solve this problem. It is available in various sizes and configurations and can provide mobile EV charging services at any time or location.

In this guide, we will take you through the critical components of the Emergency mobile EV charging system and how it works in more detail.

Battery System

Batteries are an essential part of the Emergency mobile EV charging system (EMEVCS), capable of storing energy and outputting it when needed. The battery system consists of several lithium batteries connected to form battery modules. These battery modules are then stacked and combined to form battery packs. These packs are connected to achieve the voltage and current required by the EMEVCS. This series of battery systems are suitable for UPS or energy storage systems with a battery voltage of 100V to 800V and a minimum standby time of more than 10min.

Battery Management System (BMS)

BMS is the brain of the battery system, whose primary role is to intelligently manage and maintain each battery cell, prevent overcharging and discharging of the battery, prolong the life of the battery, and monitor the status of the battery.

High voltage series BMS products are battery management systems developed for large-scale high-voltage battery energy storage systems. Distributed architecture and modular design concept are adopted, which is highly configurable and easy to assemble, debug and maintain. It is suitable for various battery energy storage systems with DC voltage below 1000V. The product can be configured as a secondary architecture (BMU + CBMs) at least, and is suitable for 10kwh-100kwh. Cooperating with industrial computer and battery stack management software, a three-level architecture (BMU + CBMs + GBMs) can be formed, which is suitable for 50kwh-2mwh occasions. Cooperating with the server and power station battery management system software, a four level architecture (BMU + CBMs + GBMs + bbms) can be formed, which is suitable for occasions from 2mwh to 1000mwh to meet different project requirements. The product has perfect and reliable operation and protection strategies to effectively prolong the service life of the battery pack. With a variety of communication interfaces, it can directly or indirectly connect with the third-party energy management system.

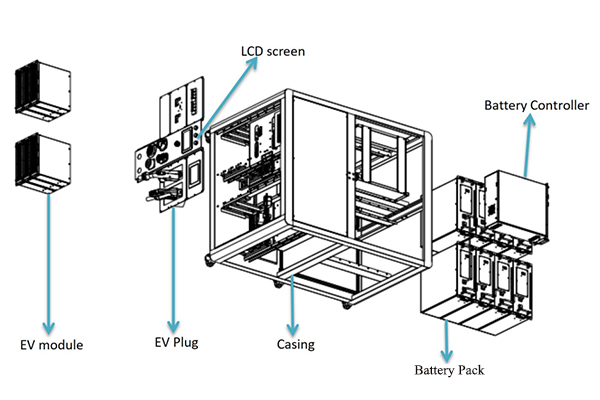

EV Charger Module

The battery system within EMEVCS stores and delivers power in the form of DC, but most electrical systems and loads run on AC. Therefore, an EV Charger Module is required for conversion.

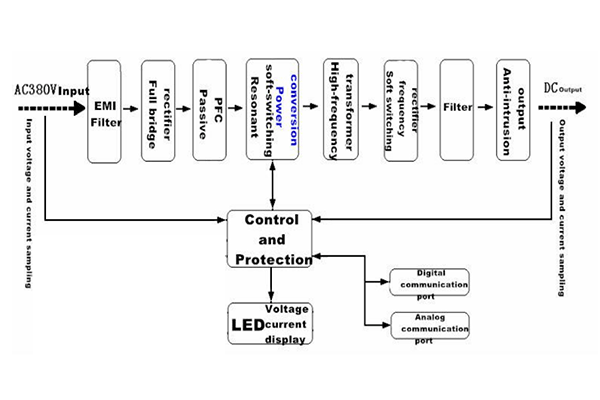

Devices connect with 380VAC three-phase city power (three-phase, five-wire), filtering by EMC; The active PEC adjust the input voltage, and current phase and the Output is full-bridge DC-DC converter circuit. When auxiliary power goes into work, the power light display and the control circuit control module start-up. DSP controls APFC and DC-DC working. When this module is used in the power system, the output voltage is set by the monitoring module or by buttons; In the absence of the monitoring module, the output voltage is 450V(initial voltage can be set according to customer requirements)

Fire Suppression

If a thermal runaway occurs in EMEVCS, the fire suppression system can produce an effect. It is distributed in each corner of the EMEVCS frame and, once activated, releases an extinguishing agent to achieve the result of absorbing heat. In case of severe cold, the heating and insulation system can be customized to meet your needs.

These are the main components of the Emergency mobile EV charging system, forming a safe and efficient charging infrastructure. At the same time, it has a robust container enclosure, and all components are assembled before shipment. It’s a solution that can be delivered quickly and yield benefits.