Heliogen and Bloom Energy demonstrate production of low-cost green hydrogen; concentrated solar and high-temp electrolysis

Green Car Congress

NOVEMBER 17, 2021

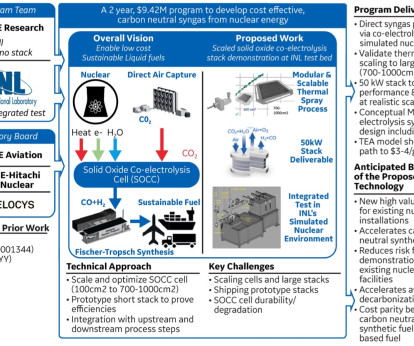

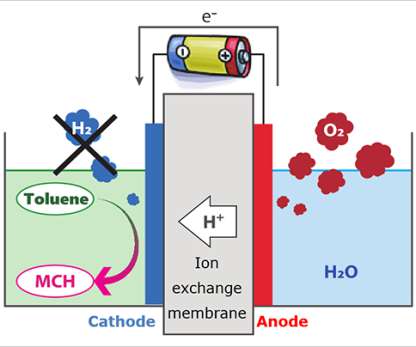

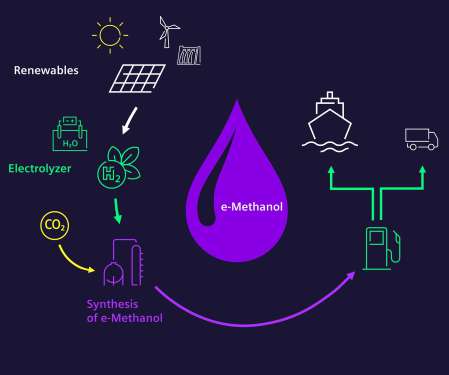

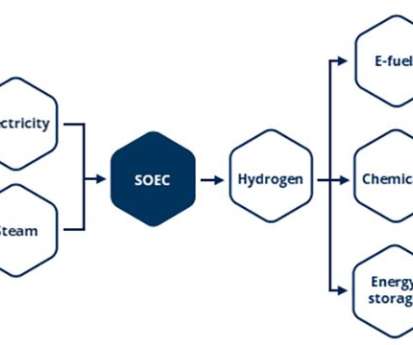

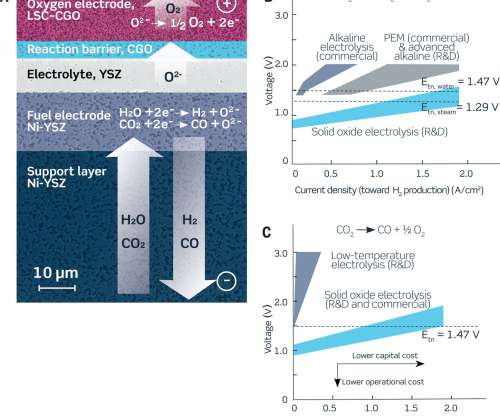

When combined with Bloom’s proprietary solid oxide, high-temperature electrolyzer, hydrogen can be produced 45% more efficiently than low-temperature PEM and alkaline electrolyzers. Electricity accounts for nearly 80% of the cost of hydrogen from electrolysis. Source: Heliogen.

Let's personalize your content