How clean is EV battery manufacturing?

It’s getting cleaner and prospects are improving

BY TIM BENFORD: PRESIDENT OF DRIVE ELECTRIC DAYTON, PAST VICE-PRESIDENT OF ELECTRIC AUTO ASSOCIATION

Green Energy Ohio plant in Dayton, OH

Scientists inform us that today’s transportation sector is the largest contributor to US greenhouse gas emissions driving climate change, but how clean are lithium-ion batteries?

First, it should be noted that while internal combustion engine (ICE) vehicles produce 17.2% of burned gasoline into energy to turn the wheels, electric vehicles (EVs) use 59-62% of the electrical energy from the battery to do the same.

Gasoline always emits 20 lbs of toxic air pollutants per gallon, and can only be burned once. This C02 stays in the atmosphere for thousands of years.

Further, according to a report from the Union of Concerned Scientists (UCS), gasoline and diesel ICE vehicle technologies fueled on a fossil/biofuel mix emit approximately 245–253 g CO2 eq./km over their lifetime. Whereas, battery EVs fueled on average grid electricity emit 105–124 g CO2 eq./km, 49% lower than the CO2 production of a comparable gasoline car. UCS also reported that once the grid is fully renewable, the number for EVs is reduced to 41 g CO2 eq./km.

So, how clean is EV battery manufacturing? Is it becoming cleaner? What is the impact on the EV lifecycle carbon footprint?

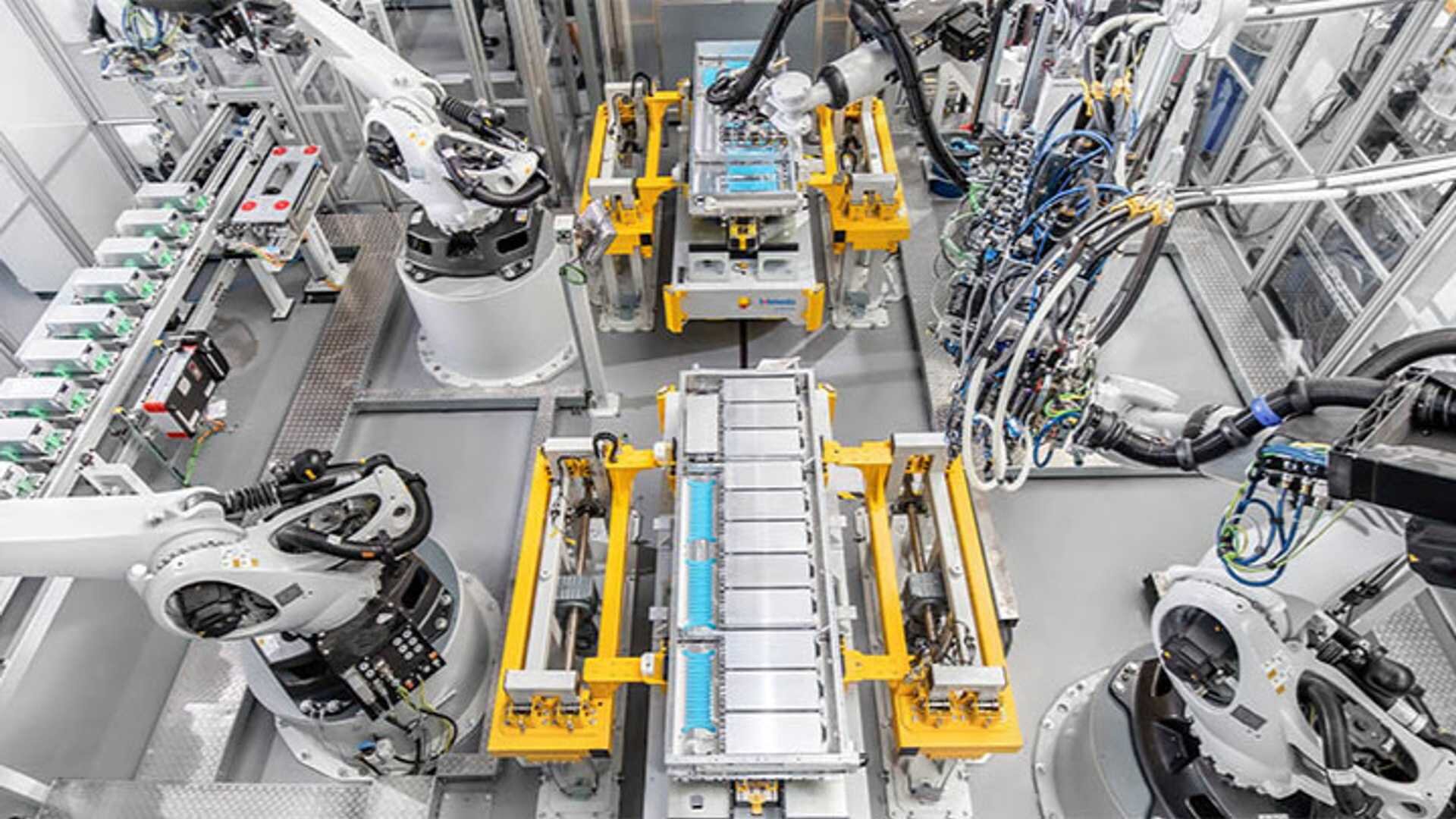

Battery manufacturing is energy-intensive

EV batteries offer the opportunity to take a huge step toward truly sustainable future mobility, but they currently carry a sizable environmental burden. Production causes more emissions than combustion engine models, an EV beginning life with a heavy "emissions debt.”

But, emissions during the battery manufacturing stage are paid off after just 2 years, a time frame that drops to approximately 1.5 years if the car is charged using renewable energy.

Optimistic outlook

The emissions from battery manufacturing are likely to decline significantly in coming decades, especially with the use of cleaner electricity throughout the production cycle. A 30% decrease in grid carbon intensity would reduce emissions from the battery production chain by about 17%.

Use of recycled materials and alternative battery chemistries could also reduce emissions in the manufacturing phase. Even as EVs use larger batteries to allow longer range, these and other improvements will further increase life cycle advantage over ICE vehicles.

The carbon footprint of the most common type of battery for EVs is estimated to be 61-106kg of CO2 emissions equivalent per kilowatt hour of battery capacity, according to the latest data compiled and modeled by battery researchers at IVL Sweden. This is 2 to 3 times lower than the 150-200kg of CO2eq estimate measured by the same researchers in 2017. This 2017 study has been used by anti-EV commentators to discredit the climate performance of EVs.

More efficient production

The EV battery manufacturing process is growing cleaner by the month with economies of scale and more renewable energy involved in the process. Tesla’s Gigafactory in Nevada is committed to manufacturing EV batteries using 100% solar energy by the end of 2019. Audi’s e-Tron batteries are manufactured at a carbon-neutral facility.

As the EV industry grows, battery recycling rates will increase, further reducing the emissions from battery manufacturing. When EV batteries degrade enough to be unsuitable for cars (about 70% capacity remaining), they are re-used for electricity storage. It is predicted that 75% of all used EV batteries will be recycled by 2025, and there is a good chance that figure will be higher. The US Energy Department recently launched a research center on lithium ion battery recycling, and recycling technologies are undergoing development and testing in China and the European Union, as well as the U.S.

Issues and answers

Concerns remain about the sustainability of lithium ion EV batteries. These concerns include: 1) labor practices for mining cobalt (2/3 of cobalt currently comes from the Democratic Republic of Congo, where it is mined using child labor and other unethical practices); 2) environmental impacts of extracting lithium from the cobalt; 3) sufficient supply of materials for EV batteries; 4) carbon emissions from battery manufacture; and 5) toxic waste from disposal of used batteries.

However, EV battery components may be very different in the near future. Many EVs, including the Nissan LEAF, already use batteries that do not rely entirely on cobalt, and for those EVs that do, the cobalt usage is likely to decline by approximately 70%. The new generation of batteries (expected to reach market within a year) will contain eight parts nickel (an abundant material) for each part of manganese and cobalt, and recycling of the cobalt in EV batteries is expanding rapidly.

Meanwhile, the US Department of Energy and many automakers are developing cobalt-free batteries, and companies are investing enormous resources in the development of new battery technologies, including the use of glass, lithium metal, lithium-sulfur, sodium, graphene, and zinc air.

Battery Usage

Electric car batteries are generally warranted for 8 years or 100,000 miles, but new EV batteries are lasting much longer—in some cases, close to 500,000 miles. Assuming a gas car would last for 200,000 miles, choosing an EV can be like getting two cars for the price of one!

Interestingly, approximately one-third of EV drivers have home rooftop solar, so their electricity is coming from sunshine, saving fuel costs as well as the environment.

EV battery packs usually last much longer than just the warranty date. If properly maintained, they should last the full lifespan of an EV (about 17 years) without having range overly restricted, according to an estimate by Consumer Reports.

Batteries get a second lease on life in stationary storage applications that connect large numbers of batteries together. The number of EV batteries at the end of their lifetime remains relatively low to date. Returns by customers do not play a major role yet, but this is expected to change significantly over the next decade.

On balance

The manufacture of EV batteries is not yet 100% clean, but is becoming cleaner as countries and companies work to improve the efficiency of obtaining the source materials and combining them into batteries with minimum carbon emissions involved.

EVs are still more expensive to buy at the outset, but they quickly pay for themselves over time in terms of financial value and reduced carbon emission when compared to ICE vehicles.

Concerns about EV batteries should not deter vehicle shoppers from considering an EV for their transportation needs. When all is said and done, EVs are more fun to drive, to maintain, to refuel, and are better for the environment than their ICE counterparts.