PYROCO2 is developing carbon capture and utilisation technology for climate-positive solutions in European chemical production.

To reach climate neutrality by 2050, we must swiftly embrace innovative, climate-positive solutions that can energise and transform the European market. Emerging approaches to carbon capture, utilisation, and storage (CCUS) hold great promise for reducing emissions in the chemical and other industries and simultaneously generating value from its major and increasingly costly side stream, CO2.

Carbon capture and storage (CCS) targets permanent large-scale storage of industrial carbon emissions. In contrast, carbon capture and utilisation (CCU) aims at valorising them in the form of new commercial products, reducing reliance on fossil or biomass-derived carbon. Therefore, CCS and CCU assume key roles as climate action and bioresource relief, respectively, in the context of effective carbon management, with the option of directly recirculating those carbon emissions that cannot easily be removed from the carbon cycle through permanent storage. In this context, the PYROCO2 project acts as a game changer for European carbon-intensive businesses, paving the way for the sustainability of Europe’s chemical industry.

PYROCO2: Pioneering biotechnology-based carbon capture and utilisation for climate-positive acetone production

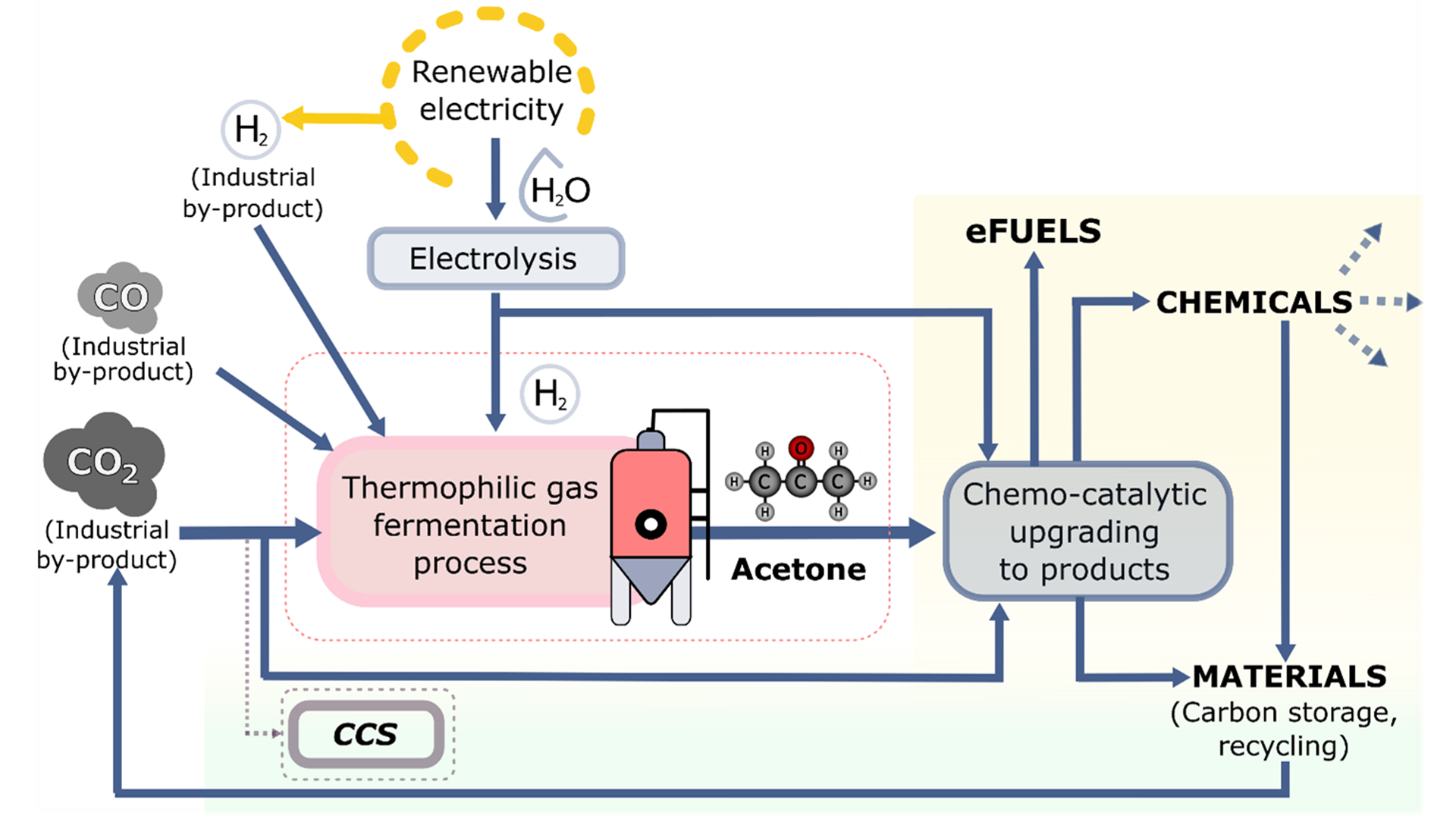

PYROCO2 is at the forefront of demonstrating the scalability and economic viability of carbon capture and utilisation to produce climate-positive acetone from industrial CO2 and hydrogen generated from renewable electricity. At the heart of this technology lies an energy-efficient thermophilic microbial bioprocess, poised to reduce an impressive 17 million tonnes of CO2 equivalent emissions by 2050. The acetone generated through the PYROCO2 process is an ideal platform for subsequent catalytic synthesis, enabling the creation of various chemicals, synthetic fuels, and materials from CO2. This will result in a diverse portfolio of viable business opportunities and pre-developed processes across various value tiers, ready for replication and commercialisation.

Acetone, (CH3)2CO, is a key commodity in the chemical industry. It is the simplest and most widely used example of the ketones chemical group and appears as a clear, colourless, volatile, and flammable liquid with a boiling point of 56°C. Acetone is completely miscible with water and most organic solvents and oils and is a common building block in organic chemistry. It is used in industry primarily to synthesise methacrylates and bisphenol A. It is further used as a solvent in many industrial applications, like in the production of plastics and synthetic fibres, for the thinning of resins, as the volatile component of paints and varnishes, and in preparing metal before painting or soldering. Global acetone demand amounted to 7.4 million tonnes in 2019, with Asia the leading region with around 52% of global consumption.1 The European market share of about 21% was roughly 1.6 million tonnes in 2019, with an expected increase of around 4% CAGR until 2030.2 Today, commercial acetone production is almost entirely from fossil resources as a by-product from, and thus linked to, phenol production using the cumene process. Sustainable large-scale biotechnological production of acetone from sugars using the Weizman process (acetone-butanol-ethanol fermentation using anaerobic bacteria) was well established during World War I, after which it was eventually abandoned and almost entirely replaced by newer methods based on fossil resources with better yields and economics, irrespective of their low sustainability. Acetone production in Europe releases approx. 2.3 million tonnes of CO2 equivalents for the estimated 1.4 million tonnes of annual European acetone production. Acetone is the central intermediate of the PYROCO2 biotechnological production platform and the chemical compound for which production will be demonstrated at the scale of up to 4,000 t/a.

Technology validation at a demonstration scale is crucial for any new technology intending to transform the market. In that light, the main aim of the PYROCO2 project is the design and construction of a demonstration plant for chemical production that enables at-scale optimisation and validation of the technology on its way toward commercial scale. It will further show that co-ordinated teamwork and close interplay of European carbon-intensive industries with some of Europe’s leading research institutions and universities can enable new technologies that reduce pollution and use CO2. The goal is to demonstrate the feasibility of using heat-thriving micro-organisms to transform CO2 and renewable electricity-derived hydrogen specifically and efficiently into acetone for subsequent demonstration of product diversification into several markets.

Demonstrator plant

The PYROCO2 demonstrator plant is planned to be situated strategically within Herøya Industrial Park in southern Norway. The Herøya peninsula, with surrounding industrial areas, represents Norway’s largest industrial cluster. The main business areas are within fertiliser, cement, metallurgy, chemical, material, and energy industries, as well as the manufacturing of electrolysers. In this region, the capture of 400,000 tonnes of CO2 is scheduled to start in 2024, connected to the large-scale CCS project ‘Northern Lights’, a part of ‘Longship’, the Norwegian Government’s full-scale carbon capture and storage project. Sustainability and decarbonisation are high priorities for Herøya Industrial Park and its clients, leveraging on the competitively priced, 100% green grid electricity. In parallel, CCUS is being evaluated as an alternative both for individual plants and in-joint solutions.

At Herøya, the PYROCO2 demonstrator plant is planned to have the capacity to produce up to 4,000 tonnes of acetone annually, utilising 9,100 tonnes of industrial CO2 and green hydrogen. The location guarantees abundant and flexible access to CO2 feedstock from different industrial sources and green energy, all while fostering industrial symbiosis by connecting various carbon-intensive industries with chemical production. This endeavour marks a significant step towards a greener, more prosperous future for Europe.

Starting at its primary demonstrator site in Norway, the PYROCO2 project will play a pivotal role in catalysing the establishment of CCU Hubs throughout Europe. In addition to establishing a comprehensive large-scale demonstration and conducting thorough financial, regulatory, and environmental evaluations of its own technology, the project will also delve into the realms of public acceptance and market development to actively promote the growth of the CCU market.

Key impacts of the project

PYROCO2 is set to achieve important goals, including creating a large-scale demonstrator by 2026. This demo will exemplify how different industries, like medical and technical gases, fertilisers, cement, metallurgy, hydrogen, chemicals, polymers, and synthetic fuels, can work together efficiently under Industrial Biotechnology. This project aims to reduce industrial CO2 emissions significantly compared to traditional acetone production methods. PYROCO2 will play a substantial role in helping the EU’s chemical industry move towards climate neutrality by introducing a cost-effective, eco-friendly process to make essential chemicals and other products. The project will also prove that the production of acetone through the PYROCO2 process is practical, feedstock-flexible, and cost-effective, paving the way for similar projects across Europe. Additionally, it aligns with the EU’s efforts to reduce air pollution, ensuring the well-being of EU citizens by cutting emissions and promoting a cleaner environment.

The PYROCO2 consortium

PYROCO2 brings together a consortium of 20 partners from ten European countries, with wide geographical coverage that extends to Thailand as the project’s outreach to the Asian market. This diverse collaboration includes eight major enterprises (Arkema (FR), DSM-Firmenich (CH), SCG Chemicals (TH), Johnson Matthey (UK), NextChem (IT), PNO-CiaoTech (IT), Herøya Industrial Park (NO), and Bioprocess Technology (ES)), three innovative SMEs (AGAIN (DK), Ranido (CZ), Ecoinnovazione (IT)), four leading academic institutions (Chalmers University of Technology (SE), Technical University of Denmark (DK), University of Lyon 1/National Centre for Scientific Research CNRS (FR), Karlsruhe Institute of Technology (DE)), three Norwegian Research and Technology Organisations (SINTEF, NORCE, NORNER), the Public-Private Cluster AXELERA (FR), and the regional authority Vestfold and Telemark County Council (NO). The project assembles leading entities across Europe, encompassing a comprehensive range of expertise required to achieve the ambitious goal of demonstrating a novel, sustainable, and economically viable pathway from industrial carbon emissions and renewable electricity to the key chemical acetone and from there onward to various other chemicals, as well as materials and synthetic fuel products, typically reliant on fossil feedstock.

PYROCO2: Leading the way in sustainable innovations and achieving remarkable milestones

While fully conceptualised and established under COVID-19 restrictions, the five-year PYROCO2 project was funded and officially launched in October 2021. With its almost €44m budget and an EC contribution of €40m, it represents one of the largest projects funded under the European Horizon 2020 Research and Innovation programme’s call for proposals in support of the European Green Deal, the co-ordinated effort to make Europe climate neutral by 2050.

Key facts about PYROCO2:

- Funding programme: Horizon 2020

- Call for proposals: LC-GD-3-1-2020: Closing the industrial carbon cycle to combat climate change – Industrial feasibility of catalytic routes for sustainable alternatives to fossil resources

Project type: Innovation action - Technology Readiness Level range: four/five to seven

- Project period: 60 months, October 2021 to September 2026

- Total project budget: €44m

- EC contribution: €40m

- Partners: 20 from 11 countries: (Norway (five), France (three), Italy (three), Denmark (two), Sweden, Germany, United Kingdom, Czech Republic, Spain, Switzerland, Thailand

- Ranked first in EC’s selection for topic GD-3-1

- Fourth largest grant awarded in Horizon 2020 in 2021

- Official project start: 1 October, 2021

- Website: www.pyroco2.eu

During its first two years of project implementation, the PYROCO2 consortium has made significant progress towards all of the project’s five main objectives:

1. Design and build a demonstrator-scale chemical production plant based on industrial symbiosis

Through its location at Herøya Industrial Park, the project has access to multiple carbon-rich gas streams from diverse carbon-intensive industries as feedstock for the biotechnology-based PYROCO2 technology. During the first phase of the project, available carbon feedstock at Herøya Industrial Park was systematically mapped, and availability for the project’s demonstrator in industrial symbiosis was ensured. Several options for sourcing green hydrogen from relevant electrolyser suppliers on-site have been identified. A 5,000m3 area has been secured for the project, and relevant permit processes have been defined and will soon be implemented. The PYROCO2 demonstrator plant represents an installation of substantial size and complexity. Bioreactor specifications and overall plant design and engineering have progressed to a point where the purchase and manufacturing of key process equipment and site preparation can soon start. At the same time, further ongoing experimental scale-up and optimisation activities at several project partners will continue. Substantial efforts have been made in the integration and optimisation of the CO2 conversion process, involving state-of-the-art biotechnological and modelling tools as guidance for the ongoing upscaling efforts to intermediate scale in 2024 and final full-scale demonstrator size towards the end of 2025.

2. Demonstrate large-scale industrial feasibility of thermophilic microbial gas fermentation

During the first two years, the project has made significant steps forward in establishing optimised and robust cell factories for the PYROCO2bioprocess to be implemented at an increasing scale. Integration and testing of the gas fermentation-based CO2-to-acetone conversion process at up to 1m3 pilot scale is currently ongoing. In parallel, the development of process modules for diversifying the product range from just acetone has made considerable progress. This included the construction and definition of operation conditions of three different chemical production pilot units, of which two were eventually deemed to be integrated with the large-scale demonstrator facility at Herøya in the last phase of the project. The aim is to show the unique combination of biotechnology and chemical catalysis in CCU technologies to produce CO2-based chemicals and polymer materials, for example, for packaging applications. In addition, experimental proof-of-concept for producing hydrocarbon fuel components from acetone has been achieved as the basis for implementing further development strategies besides the PYROCO2 project itself.

partner RANIDO in Czech Republic

3. Establish and promote PYROCO2’s new chemical production platform as a more sustainable alternative to fossil-feedstock-based production

The PYROCO2chemical production platform comprises a bundle of various value chains that, during the first 24 months, have been translated into a complete PYROCO2 process concept to guide the demo plant engineering. During the project, technological developments are guided by a set of assessments, ranging from techno-economic analysis and life-cycle costing to environmental and social life-cycle assessments of the PYROCO2 process, core technologies, and products. To promote the project and ensure the use of all its results, a comprehensive communication and exploitation strategy has been developed and implemented, aiming at disseminating the project and its results to the widest possible range of stakeholders in Europe and beyond. The first highlights were the PYROCO2 public project launch event in Porsgrunn, Norway, on 21 September, 2022, with participants from industry, policy, research and education, and the interested public, as well as the project’s first exploitation workshop that was held during the Ecomondo conference in Rimini, Italy,

on 8 November, 2023.

Norway, October 2023

4. Seek synergies with a wide spectrum of existing and future European projects for European Green transition

Since its beginning, the project has worked tirelessly to establish new links and synergies within the innovation ecosystem of research initiatives for the European Green transition. Besides a wealth of information about the project, its results and activities, the PYROCO2website features a dedicated sub-page that features the project’s sister initiatives to foster collaboration and co-ordination of activities to maximise impact. To date, PYROCO2 is actively linked with more than ten other national and EU-funded projects that are working on project-related topics, and the project team will be happy to expand this portfolio to other interested European projects that share our aims and vision for a greener future.

5. Become a key driver for the emergence of carbon capture and utilisation hubs across Europe

The PYROCO2consortium has, during the first two project years, been focusing on de-risking and evaluating the market readiness for carbon capture and utilisation hubs to replicate the PYROCO2 technology. The process started with the Auvergne-Rhône-Alpes (AURA) region in Southeast France before expanding to several other industrial clusters all over Europe in the further run of the project. Exploitation and replication strategies, as well as a toolbox for facilitating the emergence of local carbon capture and utilisation hubs, have been developed and can be obtained either directly from the PYROCO2 website or shared upon request through the contacts provided thereon.

Overall, the PYROCO2 project is well on its way to achieving its mission to bring Europe closer to climate neutrality by 2050 while maintaining the competitiveness of the European chemical industry sector.

PYROCO2 has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 101037009.

PYROCO2 has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement No 101037009.

References

- ICIS Top 100 Chemical Distributors, May 2020. ChemAnalyst Europe acetone market.

- Acetone Market Trends, Demand 2020-2027. Reports and Data.

Please note, this article will also appear in the sixteenth edition of our quarterly publication.