Experts at the University of Illinois Chicago (UIC) have developed an innovative carbon capture system that enables the carbon-negative production of ethylene.

The groundbreaking machine obtains carbon from flue gas and converts it into ethylene, a significant step towards green ethylene production. The first-of-its-kind technology integrates a carbon capture system with an ethylene conversation system, which not only runs on electricity but also removes more carbon from the environment than it generates, meaning it produces net-negative emissions.

Meenesh Singh, UIC Assistant Professor in the Department of Chemical Engineering, commented: “This is the first demonstration of a net-negative, all-electric integrated system to capture carbon from pollutants and create a highly valuable resource. This is an important milestone in ethylene decarbonisation.”

The study, ‘Fully-Integrated Electrochemical System that Captures CO2 from Flue Gas to Produce Value-Added Chemicals at Ambient Conditions,’ is published in the journal Energy & Environmental Science.

Ethylene emissions need to be reduced urgently

Of all the manufactured chemicals worldwide, ethylene ranks among the top three for the highest carbon emission, only coming behind ammonia and cement. Ethylene is utilised to manufacture plastic products for packaging, agricultural, and automotive industries, but is also used to create chemicals used in antifreeze, medical sterilisers, and vinyl siding for houses.

Singh explained: “There is an urgent need to develop efficient technologies for integrated carbon capture and conversion to sustainably produce net-negative fuels. Currently, integrated carbon capture and conversion systems are highly energy-intensive and work in a discontinuous cycle of carbon dioxide capture and reduction. Efficiently integrating carbon capture with the conversion system eliminates the need for transportation and storage, thereby increasing its energy efficiency.”

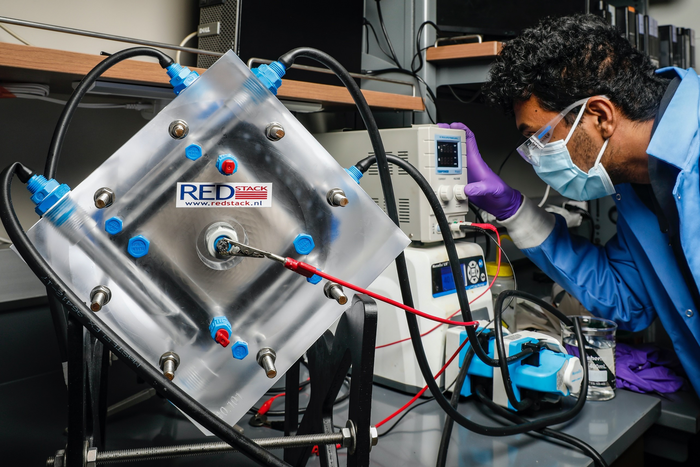

Developing the carbon capture system

The researchers modified a traditional artificial leaf system with inexpensive materials to include a water gradient – a dry and wet side – across an electrically charged membrane to capture carbon from the air or flue gas.

The dry side included an organic solvent that binds to available carbon dioxide to produce a concentration of bicarbonate on the membrane. As the bicarbonate accumulates, these negatively charged ions are pulled across the membrane toward the positively charged electrode in a water-based solution on the wet side of the membrane. Subsequently, the liquid solution dissolves the bicarbonate back into carbon dioxide so it can be released and used for CO2 conversion.

The team employed a second system to convert the captured CO2 into ethylene, in which an electric current is passed through a cell. Half of the cell is comprised of captured carbon dioxide from a carbon capture system, with the other half containing a water-based solution.

An electrified catalyst pulls charged hydrogen atoms from the water molecules into the other half of the unit, which is separated by a membrane, where they combine charged carbon atoms from the carbon dioxide to produce ethylene.

The researchers amalgamated the two systems by feeding the captured carbon dioxide solution into the carbon conversion and recycling it back. This closed-loop recycling process provides a constant supply of carbon dioxide from flue gas, converting it to ethylene.

How did the system perform?

The team tested the integrated system using a 100-square-centimetres bipolar membrane electrodialysis unit to capture carbon dioxide from flue gas and hydraulically connected it to the one-square-centimetre electrolysis cell to create ethylene. The system was tested continuously for one week, demonstrating exceptional stability and capturing carbon at a rate of 24 grams daily, producing ethylene at 188 milligrams per day.

Singh concluded: “In the journey to make ethylene production green, this is a potential breakthrough. Our next step is to scale up the integrated carbon capture and conversion system to produce ethylene at higher rates — a rate of one kilogram per day and capture carbon at a rate higher than kilograms per day.”