Lamborghini introduces new monofuselage carbon fiber monocoque concept

Green Car Congress

MARCH 15, 2023

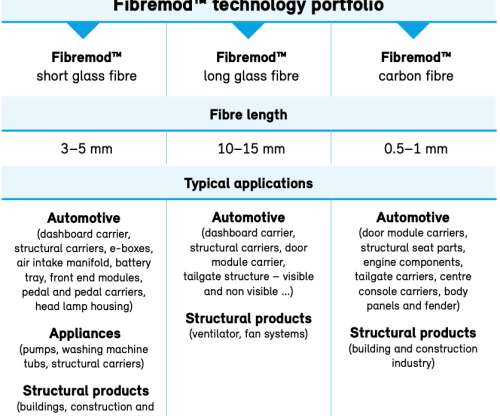

As well as a monocoque made entirely of multi-technology carbon fiber, it features a front structure in Forged Composites; a special material made of short carbon fibers soaked in resin. The LB744 is also the first super sports car to be fitted with a 100% carbon fiber front structure.

Let's personalize your content