Continental Structural Plastics perfects carbon fiber RTM process, launches production programs

Green Car Congress

DECEMBER 4, 2020

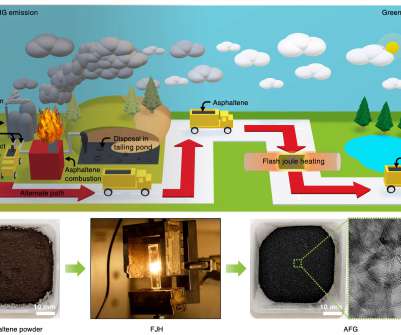

Continental Structural Plastics (CSP) has fine-tuned its carbon fiber RTM (resin transfer molding) (CF-RTM) process to the point that a premium automaker will be using the technology for closures on future vehicle platforms. We have been targeting a 3-minute cycle time using 100 percent recycled carbon fiber.

Let's personalize your content