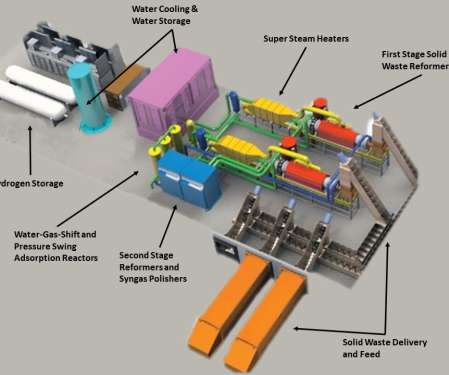

Raven SR & Hyzon Motors to build up to 100 waste-to-hydrogen hubs

Green Car Congress

APRIL 28, 2021

a global supplier of hydrogen fuel cell-powered commercial vehicles, announced a joint venture to build up to 100 hydrogen hubs across the United States and globally. This permits the control of the rotary reformer when there is water content or chemical makeup variation in the feedstock, such as in MSW.

Let's personalize your content