Raven SR & Hyzon Motors to build up to 100 waste-to-hydrogen hubs

Green Car Congress

APRIL 28, 2021

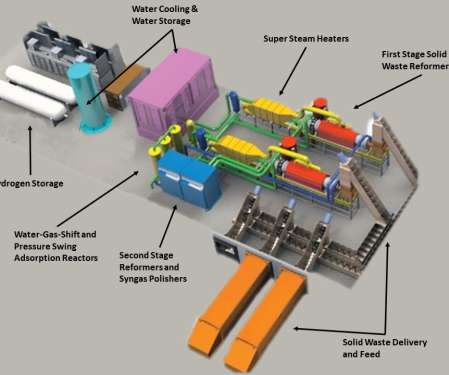

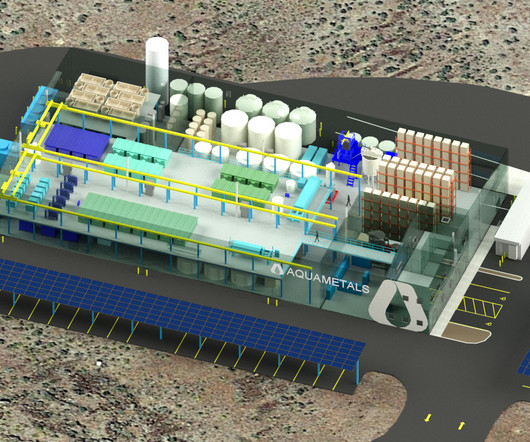

a global supplier of hydrogen fuel cell-powered commercial vehicles, announced a joint venture to build up to 100 hydrogen hubs across the United States and globally. Raven SR’s patented, Steam/CO 2 Reformation process enables it to be one of the only combustion-free, waste-to-hydrogen processes in the world. 22 CCR § 66260.10

Let's personalize your content