Stellantis N.V. and Orano have signed a Memorandum of Understanding (MoU) to collaborate on a globally significant electric vehicle battery recycling project.

The joint electric vehicle battery recycling venture will recover materials from end-of-life batteries and scrap from gigafactories in Europe and North America.

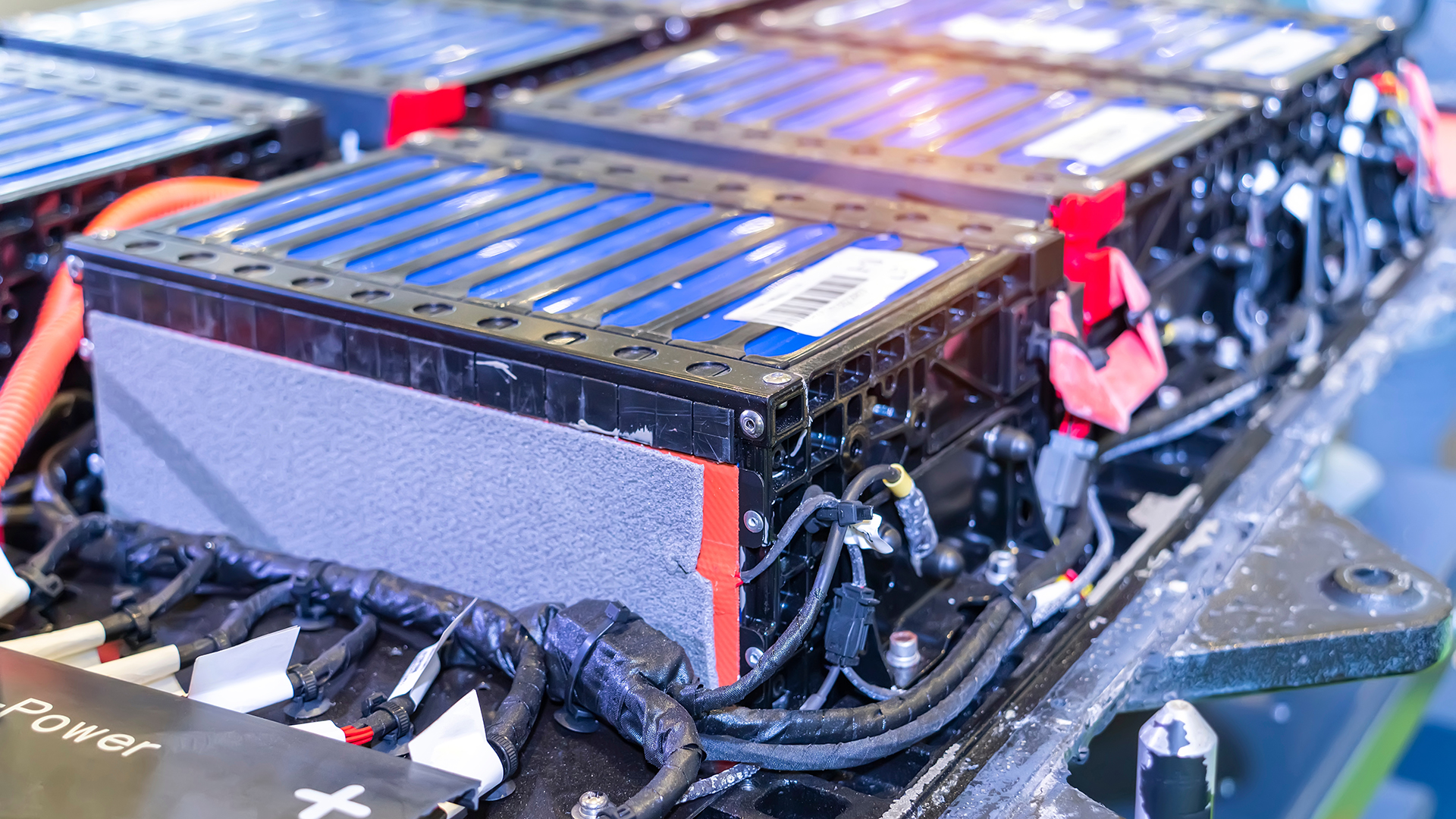

The endeavour will provide a significant boost to Stellantis’ battery value chain, yielding cobalt, nickel, and lithium, which is essential for battery production.

The project is expected to be operational at the start of 2026, with both organisations reskilling and upskilling their employees to close the green skills gap and retain jobs.

Speaking on the announcement, Guillaume Dureau, Orano Group Director of Innovation, R&D and Nuclear Medicine, Magnets and Batteries, said: “We are delighted with this partnership with a major player such as Stellantis to work together in the recycling of used electric batteries.

“We are proud to bring our expertise and know-how with our innovative and disruptive process, which allows a real closed loop.

“Orano continues its commitment to developing a low-carbon economy with the recycling of strategic materials for the energy transition and the circular economy.”

Stellantis’ circular economy mission

As outlined in the company’s Dare Forward 2030 strategic plan, Stellantis’ Circular Economy Business Unit aims to increase recycling revenues tenfold and generate over $2bn in circular economy revenues by 2030.

Due to these ambitious targets, the company is on track to become net zero by 2038, with the latest electric vehicle battery recycling venture being instrumental in this mission.

Alison Jones, Stellantis Senior Vice President, Circular Economy Business Unit, echoed the significance of the partnership: “The United Nations’ Sustainable Development Goals has confirmed the need to find solutions like this one with Orano to meet the challenge of natural resource scarcity and sustainability.

“Guided by our Dare Forward 2030 strategic plan, Stellantis is committed to shifting its production and consumption model by fulfilling its circular economy commitment.”

The project will recover 90% of electric vehicle battery materials

The joint venture leverages Orano’s groundbreaking, low-carbon technology, which departs from conventional methods and facilitates the complete retrieval of materials from lithium-ion batteries, as well as the production of fresh cathode materials.

These materials are commonly referred to as ‘black mass’ or ‘active mass’. They can be further refined in Orano’s upcoming hydrometallurgical plant in Dunkirk, France, with the aim of making them suitable for reuse in batteries, thereby promoting the principles of a circular economy.

Thanks to its innovative pre-treatment approach and state-of-the-art hydrometallurgy technology, this joint venture achieves exceptional metal recovery rates exceeding 90%.

This accomplishment enables original equipment manufacturers (OEMs) to meet the recycling rate targets set by the European Commission for electric vehicle batteries, thereby ensuring the sustainability of their business model.