The Elestor battery is proving to be the ideal solution to reliable and efficient energy storage in the transition to green energy.

As the transition to sustainable energy progresses, reliance on intermittent, unpredictable sources like sun and wind continuously increases while the predictable generation of fossil-based electricity is faded out.

Though occurring statistically only once or twice per year, these changes in the electricity generation lead to dark and windless periods – in German referred to as the ‘Dunkelflaute’ – sometimes lasting several days. The question to be answered is how such periods can be managed to ensure the availability of sufficient electrical energy at any time and at the lowest possible costs.

Electrolysers, gas-fired power plants and fuel cells

One way to bridge the gap is to convert a surplus of electricity, generated by sun and wind during periods of overproduction, into hydrogen using electrolysers. The hydrogen can then be converted back into electricity by gas-fired power plants running on green hydrogen. This is a proven approach, which applies already established technologies utilised with fossil-based sources. In essence, the combination of electrolysers and gas-fired power plants act as an electricity storage system – a battery.

Economically, this is a different story. Analyses show that these hydrogen-powered gas-fired power plants will only be operational for 10% of the time. Moreover, it is far from efficient to produce hydrogen from green electricity via electrolysis and then to generate electricity again through combustion in a gas-fired power plant. Each individual step displays an energy efficiency of about 60%, resulting in an overall energy loss of two thirds.

With such low efficiency, it is necessary to triple the capacity of renewable energy generation, which is accompanied by tripled costs and time. Lastly, these solutions need to be kept operational all year round in order to step in only occasionally. This low utilisation leads to very high costs per ‘stored’ megawatt hours (MWh).

Fuel cells could be considered as an alternative to gas-fired power plants, converting hydrogen and oxygen into electricity and water. However, with a fuel cell efficiency of around 60%, this combination also results in a two-third energy loss, while also the utilisation of two installations is low.

The role of batteries

To address those longer of periods of time during which little or no electricity is generated, the key concern is how large reserves of electrical energy can be realised in the most efficient and economical way.

Electricity storage technologies are available in many forms and sizes such as: pumped hydro, compressed air, flywheels, super capacitors, electrochemical batteries and many more. Obviously, there is no silver bullet technology solving every storage need, but each technology holds unique properties that determine its ideal application.

Lithium-ion batteries are, for instance, the absolute champion in energy density, making them the ideal solution for mobile technologies, electrical vehicles and possibly even maritime challenges.

Flywheels are extremely fast, but can only deliver power for a very limited period of time, meaning they are only suitable for applications in which the short and fast delivery of peak powers is needed or need to be absorbed.

The most distinguishing and unique property of flow batteries is that their power (megawatts, MW) and capacity (MWh) are not coupled. With conventional batteries like lithium-ion or lead acid, power and capacity are coupled, meaning that a high capacity also comes with a high power. To sustain longer periods of time, only the battery capacity must be higher, not the power.

For this reason, flow batteries offer the most economical and durable solution, while the lithium-ion battery is the technology of choice in applications where only a few hours are to be covered. In other words: the lithium-ion battery is the sprinter, the Elestor battery technology is the marathon runner.

The Elestor battery as bi-directional power plant

Two years ago, Elestor conducted an in-depth analysis aiming to identify the most economical 100% carbon-free electricity supply, generated by sun and wind, at the lowest possible cost and maintaining the same reliability and availability of electricity.

The study made use of detailed historical data on the generation of wind and solar energy over an entire year, so included all seasons. As expected, sun and wind turned out to be fairly complementary, so when the sun doesn’t shine, the wind often blows and vice versa. It is therefore essential to first define the optimal ratio sun and wind generation.

The analysis concluded that, with the optimal sun and wind combination, a maximum of 130 hours need to be covered, and that periods of this length occur only incidentally, once or twice per year. To sustain the availability of electricity, stored reserves of electrical energy are required to compensate during these intervals.

An Elestor battery can easily bridge more than 130 hours, and does so in the most economical way. Moreover, the same battery can be used not only during these rare intervals but also for grid balancing, resulting in an almost continuous utilisation as opposed to the 10% mentioned above for electrolysers and gas-fired power plants.

The overall efficiency of the Elestor battery technology is twice as high as that of the electrolyser and gas-fired power plant combination. Not only regarding total capital expenditure but also in terms of energy efficiency, the Elestor solution is the better alternative. The Elestor battery is a candidate for the bi-directional power plant of the future and, with it, gas-fired power plants will be obsolete. A bi-directional power plant cannot only supply electricity, but can also be charged.

Using batteries instead of gas-fired power plants is a development already underway in the US. On the Moss Landing Project, a complete gas-fired power plant has been replaced by a large battery and energy company, Vistra, that will eventually replace its gas-fired power plants for back-up purposes with batteries, with a total power of 6,000 MW.

Electrolyser and fuel cell combined in one single system

When taking a closer look at the working principle of the Elestor battery, it is both an electrolyser and a fuel cell and is therefore also referred to as a ‘reversible fuel cell’.

Capital expenditure

In the Elestor system, both electrolyser and fuel cell functionalities are combined in one single piece of hardware. Both processes make use of the same equipment as opposed to individual electrolysers and gas-fired power plants (or fuel cells), resulting in a much lower capital expenditure for the Elestor battery despite their same functions.

Efficiency

Another essential difference is that the electrolyser and fuel cell functionality of the Elestor battery is not based on the traditional hydrogen (H2) and oxygen (O2) chemistry, but uses hydrogen and bromine (Br2). This difference leads to energy efficiency double that of the electrolyser and gas-fired power plant (or fuel cells) combination.

The charging (‘electrolysis’) and discharging (‘fuel cell’) processes each have an efficiency of around 90%. The roundtrip chemical efficiency is therefore around 80%. So-called parasitic losses for auxiliary systems that all batteries have – like battery management systems, inverters, sensors and safety systems – add up to losses of 5-10%, resulting in an overall efficiency of around 70%.

In conclusion, analyses show that the Elestor flow battery is an ideal candidate for substituting gas-fired power plants in the form of bi-directional power plants. Its capital expenditure is much lower, its efficiency is twice as high, and its utilisation is almost continuous in comparison to the current solution based on traditional electrolysers and gas-fired power plants running on hydrogen.

A new energy system requires innovative solutions. Old systems shouldn’t be kept alive.

Technology fundamentals

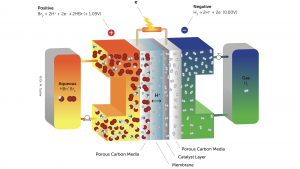

The illustration (below) shows the fundamental working principle of the Elestor battery.

A system consists of two tanks, of which the left tank contains hydrogen-bromide (HBr) and the right tank is to store hydrogen (H2). Both tanks are part of an individual closed circuit, which come together at the centre at the so-called membrane. This membrane has a specific property in only allowing hydrogen ions H+ (protons) to pass through.

Charging: Electrolyser

When charging, the HBr molecules in the left tank are split into H+ ions (protons) and BR– ions. The H+ ions cross the membrane, absorb an electron and form hydrogen. This hydrogen is stored in the right tank. The Br – ions stay in the left circuit, release electrons and form Br2. This charging process is fundamentally an electrolysis. While with traditional electrolysis H20 is split into H2 and O2, the Elestor battery splits HBr into H2 and Br2.

Discharging: Fuel cell

When discharging, H2 and Br2 molecules are combined into HBr again. The H2 molecules release two electrons and form two each H+ ions (protons). These protons cross the membrane and form HBr in the electrolyte circuit.

This discharging process is fundamentally a fuel cell process. While with traditional fuel cells H2 and O2 is recombined into H2O, the Elestor battery recombines H2 and Br2 into HBr.

Please note, this article will also appear in the fifteenth edition of our quarterly publication.