A digital twin approach to improve the performance of EV battery cells.

Battery cell design optimization is intricate, involving a multitude of design parameters such as cell geometry, electrode micro-structure, and materials properties. These parameters often have conflicting effects on key requirements. For example, increasing electrode thickness can enhance energy density but may come at the expense of fast-charge capability.

In this 60-minute webinar, Xavier Conqui and Aziz Abdellahi from Simcenter demonstrate the effectiveness of an incremental engineering approach using digital twins in optimizing battery cell design against vehicle requirements.

With a focus on the electrochemical performance of battery cells, the experts will demonstrate how a digital twin approach helps to navigate the complexity of battery cell design optimization. They will delve into the crucial factors that shape EV battery requirements, including fast-charge capability and energy density.

Key topics and takeaways

- Trade-off potentially conflicting design parameters early on

- Predict the impact of li plating on fast-charge capability

- Utilize vehicle-level simulations to identify specific requirements at the cell level

- Employ a fast system simulation approach for the initial cell design phase

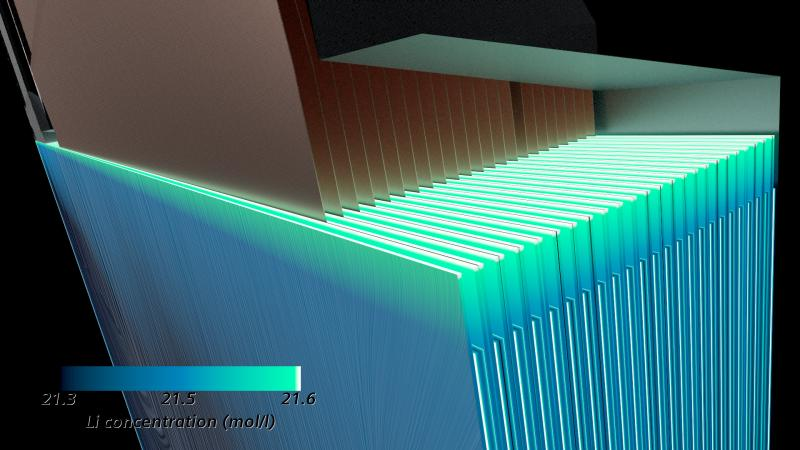

- Advance to a detailed 3D simulation approach to refine the battery cell design

Join the webinar and ask your questions live

This webinar will be hosted by CHARGED on Wednesday 13th March at 11am US ET