OneD Battery Sciences and Koch Modular said on Wednesday they have teamed up to build a factory in North America to produce enough silicon-graphite anode material to supply batteries for around 1 million EVs annually.

The two companies will announce the location for the factory, which should cost a “few hundred million dollars” in the near future, CEO Vincent Pluvinage told Reuters.

OneD is one of a number of startups developing silicon anode materials, including GDI, Nexeon, and Sila Nanotechnologies, all touting better EV battery performance than graphite.

China refines more than 90% of the world’s graphite for almost all EV battery anodes and introduced export curbs for graphite in December.

This has spurred automakers’ efforts to source synthetic graphite or use alternative materials such as silicon outside of China.

OneD adds silicon nanowires to graphite EV battery anode material to boost range and cut charging time, while also reducing weight. The company says the process also saves money for automakers seeking affordable EV models. Nanowires are ultra-thin wires.

General Motors is a OneD investor and customer.

Pluvinage said OneD is “already in negotiations” with customers to build a similar plant in Europe.

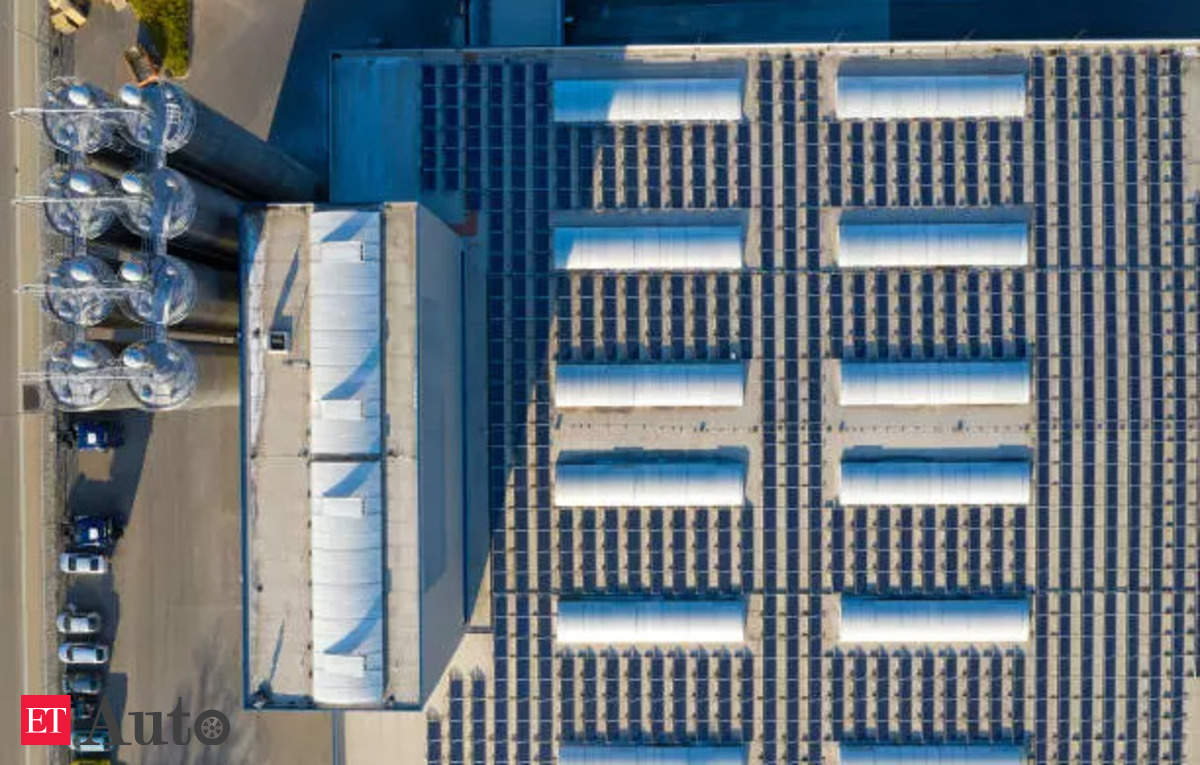

Koch Modular, minority-owned by U.S. conglomerate Koch Industries, will design and build a silane gas plant to remove impurities from silicon for the factory where OneD will combine it with graphite to make silicon anode materials.

Over the last decade, Chinese suppliers have flooded the market for polysilicon – high-purity silicon – market with cheap supplies, making new U.S. production uneconomical, Koch Modular president George Schlowsky told Reuters.

But a U.S. push via the Inflation Reduction Act and moves in Europe to own more of the EV supply chain have helped make a U.S. silane plant a viable option.

“There was never any thought in my mind that we’d ever sell another silane plant again,” he said. “But due to the desire… for the Western world to own the technology, our silane production system is available once more.”