Freudenberg Sealing Technologies offers material testing for lithium-ion battery electrolytes

Green Car Congress

MARCH 17, 2021

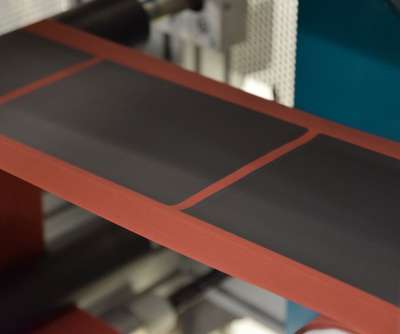

Freudenberg Sealing Technologies (FST) has expanded its material testing capabilities to include performance and compatibility evaluations of the rubber, elastomers and thermoplastics used to seal and safely maintain lithium-ion batteries. Source: FST. This work focuses upon the impact the electrolyte has on the materials.

Let's personalize your content