Renault Group and Phoenix Mobility launch electric retrofit of commercial vehicles; Renault Master kit first

Green Car Congress

JULY 19, 2022

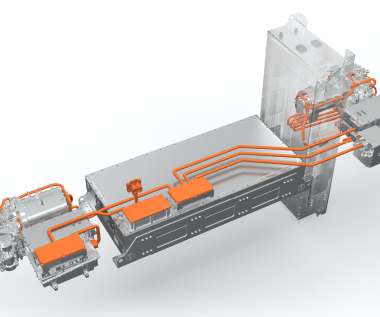

Renault Group and Phoenix Mobility , a Grenoble-based company specializing in the conversion of commercial vehicles to electric power, have signed a letter of intent to form a strategic partnership for the development and commercial operation of a retrofit kit, the first of its kind in the French LCV market.

Let's personalize your content