GM battery fabrics funding in Quebec to manage $1 billion

Baua Electric

JUNE 2, 2023

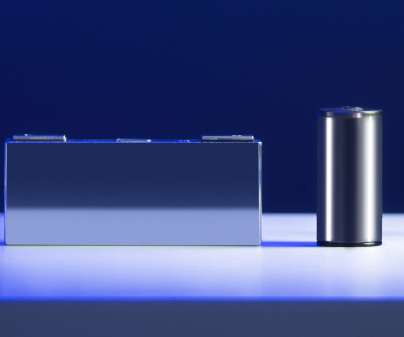

CAM contains parts equivalent to processed nickel, lithium and alternative fabrics that produce up about 40 in step with cent of the price of a battery. The Quebec and federal governments are kicking in C$150 million every. It’ll assemble cathode energetic subject material (CAM) for EV batteries.

Let's personalize your content