As Volkswagen ramps up to build a new generation of mass-market electric vehicles in the aftermath of its diesel scandal, regulators and environmental groups will likely be paying close attention to their emissions—especially the emissions created in making them.

The Financial Times, in a Sunday report, presented some interesting pieces of information based on an interview with Marco Philippi, the corporate director for procurement for the VW Group, which oversees not just VW but Audi and many others.

In the upcoming ID Neo, the first MEB vehicle, which reaches the market late this year in Europe, the carbon emissions impact from the supply chain is 150 percent higher—2.5 times higher—than that of a Golf TDI.

DON’T MISS: VW’s new U.S. CEO: The tipping point on EVs is already here

Given that, it’s not surprising that VW has made some very strong demands to its suppliers—that as plans for its new generation of fully electric cars come together, they’ll need to comply with new, tighter rules about carbon emissions from their operations.

Volkswagen, among other automakers, already issues annual sustainability reports that have made sure that its suppliers—not just the top-tier ones, but down the supply chain—comply with environmental and social standards. One such example is the use of conflict minerals like cobalt.

What's new is the closer monitoring of carbon emissions, which has only in the last decade become a point of pride for top-tier suppliers. By adding second- and third-tier suppliers, VW will have a much more accurate picture of how much energy is going in—and the total emissions involved.

CHECK OUT: Volkswagen details the foundation for 10 million electric vehicles

All 40,000 suppliers could soon be issued “S-ratings,” for sustainability, that would affect their future use by the global automaker.

Philippi remarked to FT that right now for EVs the focus is on the reduction of cobalt and cutting the cost of manufacturing. So the carbon piece may prove an additional puzzle for some suppliers.

“This is a revolution,” said Philippi. “If there are violations, our partners will not be our partners.”

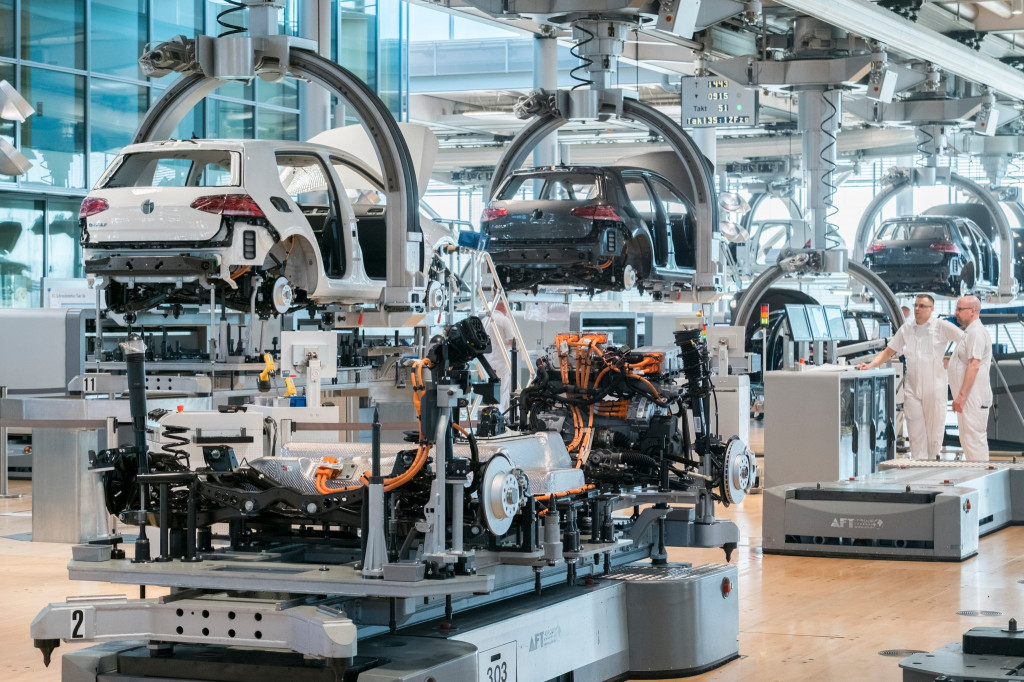

2018 Volkswagen e-Golf electric cars on assembly line in

The company has already made some large-scale changes to clean up its manufacturing. The cornerstone of that effort is its Zwickau factory, where VW has committed to convert from the production of 300,000 internal-combustion-engine vehicles a year to the same number of all-electric cars by 2021. It calls that facility, which is run by Austrian hydro-power, “Europe's most efficient e-car factory.”

The battery packs are what drives manufacturing carbon impact so high for EVs, relative to internal-combustion vehicles. VW has previously declared that its batteries, down to the cell production, will also be made with green energy.

READ MORE: Charging ahead: VW follows Tesla into power business

VW already plans to make other significant green-manufacturing commitments around the world, including two more plants in Germany, two in China, and an $800 million expansion in Chattanooga, Tennessee that will bring that plant an additional 1,000 jobs with the company and many more at suppliers.

The strategy also fits right in with VW’s creation, last month, of Elli, the company’s “electric life” affiliate that will sell all the ancillary home-related services to electric-vehicle ownership, such as clean power, energy storage, and charge points, in what we see as an attempt to help owners in all regions lower their carbon impact as well. So far, the service is limited to Europe.