LeMond Carbon obtains independent verification of its carbon fiber rapid oxidation technology

Green Car Congress

DECEMBER 22, 2019

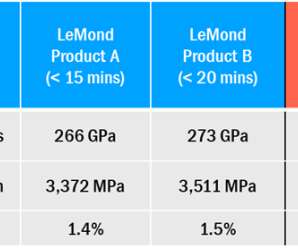

LeMond Carbon announced the results of an independent technical audit conducted by Bureau Veritas (BV) of its carbon fiber manufacturing process. The audit was conducted on a pilot line at Deakin University’s Carbon Nexus facility in Geelong, Australia. This is a significant milestone for our company.

Let's personalize your content