The town of Namie, in eastern Japan, was devastated by the earthquake and tsunami of 2011, and has struggled to recover from the devastation of that day.

Almost seven years later, the first new plant in town is set to open, one contributing to clean energy and zero-emission vehicles to boot.

Carmaker Nissan and an arm of the giant trading company Sumitomo will open a plant to analyze, reuse, and recycle used and end-of-life battery packs from Nissan's electric cars.

DON'T MISS: Used electric-car batteries should be recycled, not reused: report (Dec 2016)

Nissan and Sumitomo together have set up a joint-venture company called 4R Energy Corpoation, which will operate the new plant.

It is scaled to accommodate rapid growth in the number of used electric-car batteries that become available as the earliest Nissan Leaf electric cars reach the ends of their lives.

Japan has very strict inspection rules for older vehicles that essentially make it cheaper to scrap cars that are five or seven years old than to keep them on the road, meaning that first-year Leafs from 2011 will start to come up for dismantling this year.

![2011 Nissan Leaf electric car after battery-pack replacement [by owner Tim Jacobsen, Concord, CA] 2011 Nissan Leaf electric car after battery-pack replacement [by owner Tim Jacobsen, Concord, CA]](https://images.hgmsites.net/med/2011-nissan-leaf-electric-car-after-battery-pack-replacement-by-owner-tim-jacobsen-concord-ca_100599982_m.jpg)

2011 Nissan Leaf electric car after battery-pack replacement [by owner Tim Jacobsen, Concord, CA]

The 4R company was actually established in 2010, even before the Leaf went into mass production, anticipating the need that has now arisen. It has gained, the partners said, "valuable expertise" in that field since then.

Batteries will arrive at the Namie plant not just from Japan, but sourced from dismantled Leafs and e-NV200s all over the world.

The company has developed a system to measure the performance of the battery as a whole and that of individual modules, letting it assess which components and subassemblies can be reused and which should be recycled.

CHECK OUT: New life for old Nissan Leaf electric car: battery replacement and what it took

Components with remaining energy capacity will be reused and reassembled into "refabricated" battery packs, some of which will be offered as lower-cost replacement batteries for older electric cars.

Others will find new homes in applications ranging from electric forklifts that can be frequently recharged to large-scale energy storage systems for electric utilities, factories, and many other applications.

In general, a battery pack is considered at the end of its life for automotive use when its energy-storage capacity has declined to about 70 percent of the original rating.

Honda's process for recycling nickel-metal hydride batteries

That still leaves it entirely usable for other applications, especially those without the frequent deep discharge cycles of use in vehicles that may travel long distances at high speeds.

With growing concerns over the availability of rare-earth metals and other battery components, not to mention the environmental costs of mining them, battery recycling is widely expected to become a thriving industry.

READ THIS: Honda Recycles Hybrid Battery Packs Into Rare-Earth Metals For New Ones (Mar 2013)

It's also viewed as a way for vehicle owners to recapture some of the value from battery packs even after they're no longer suitable for automotive use.

There's precedent for a global system of automotive battery recycling, too, not only among all makers of hybrid-electric cars but for an even simpler and far more ubiquitous type of battery.

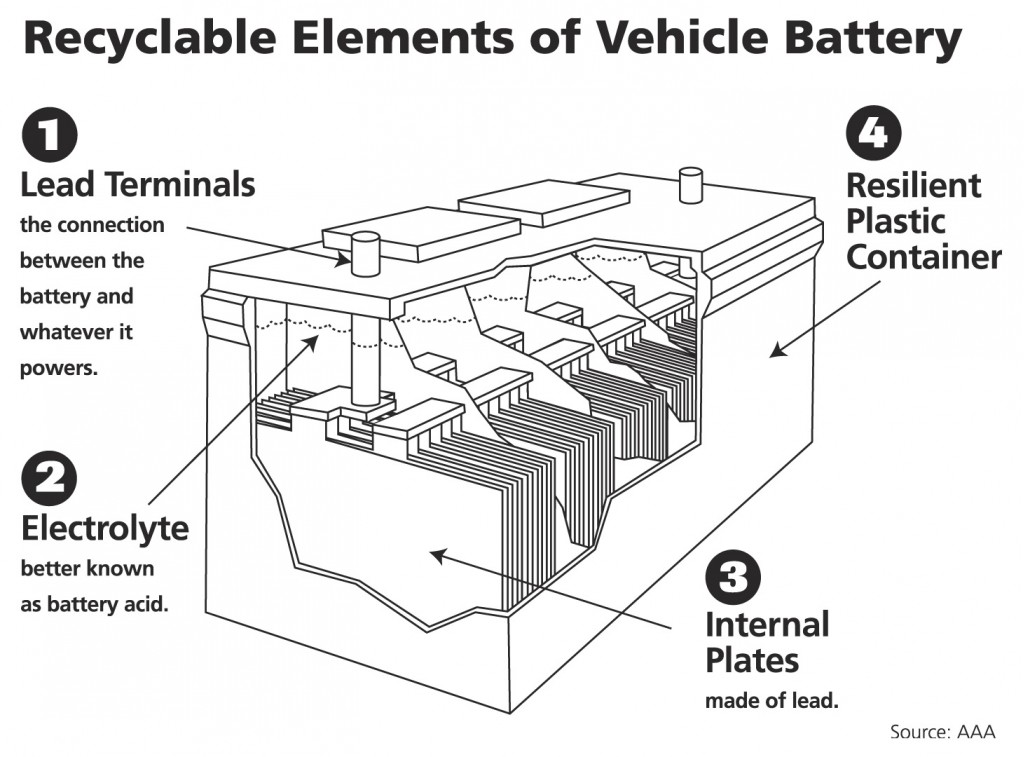

car batteries are highly recyclable - AAA

The standard 12-volt starter battery is the most recycled consumer good in the world, due in part to the high toxicity of the lead used in its electrodes.

Lithium-ion cells, on the other hand, are largely inert and are not considered toxic to human health.